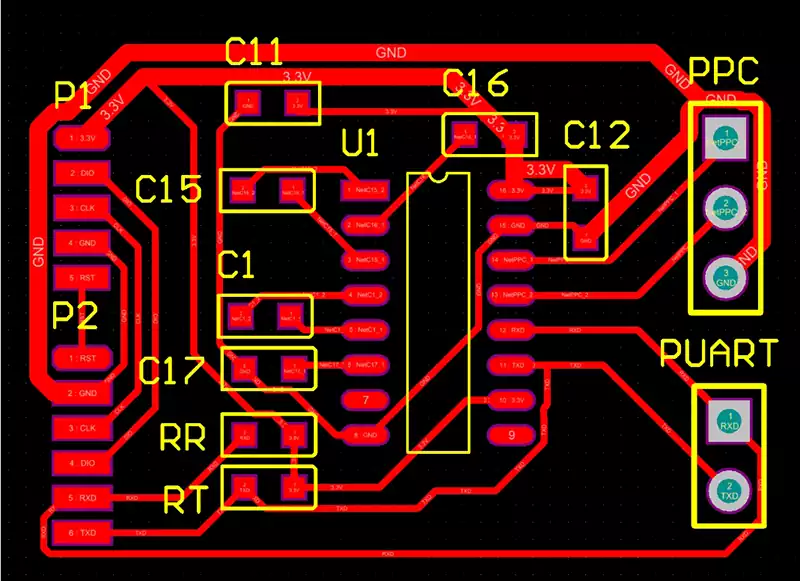

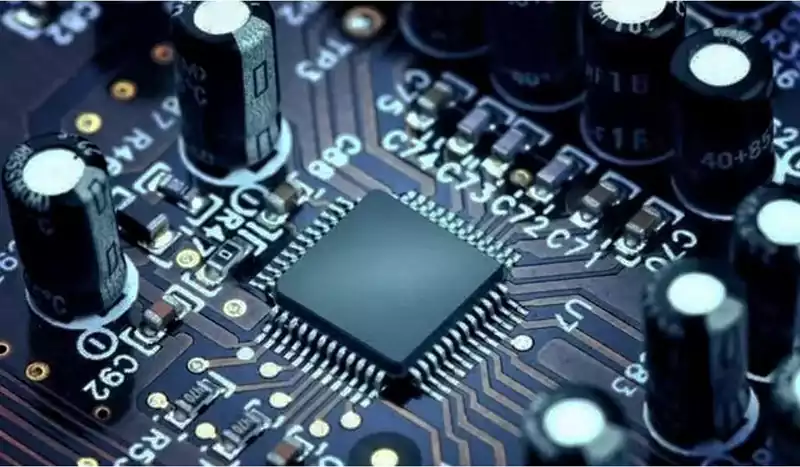

PCB layout rules and guidance

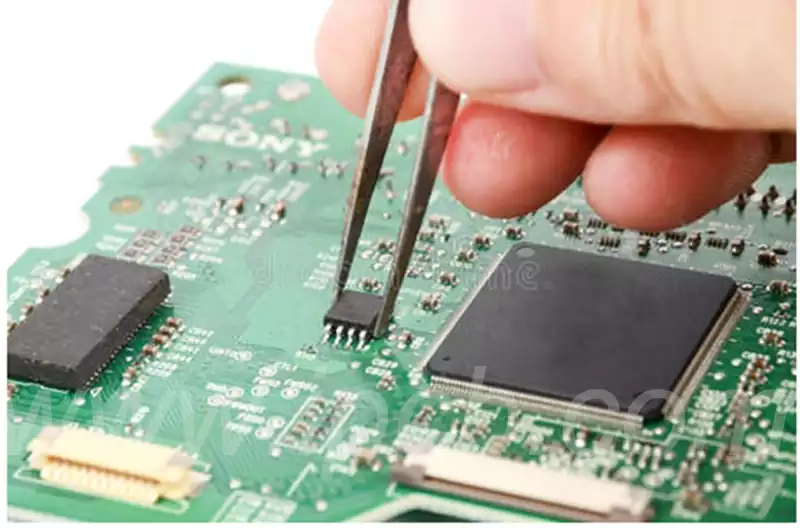

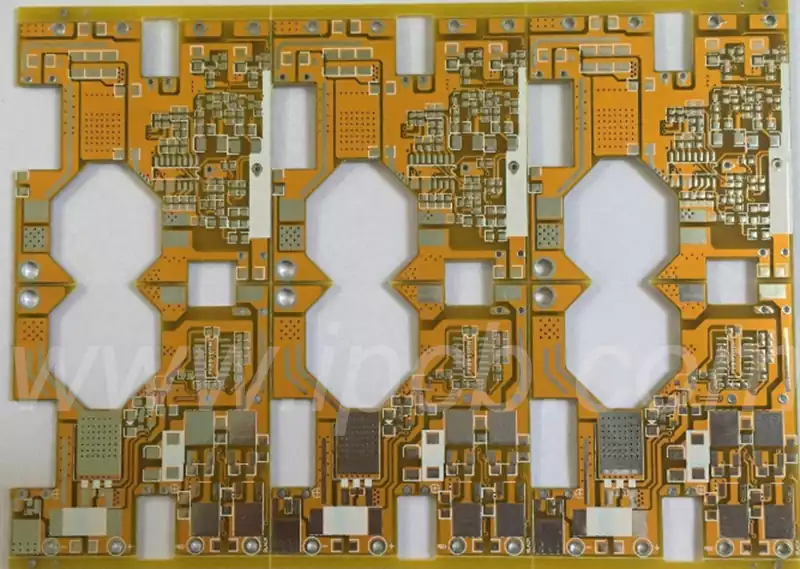

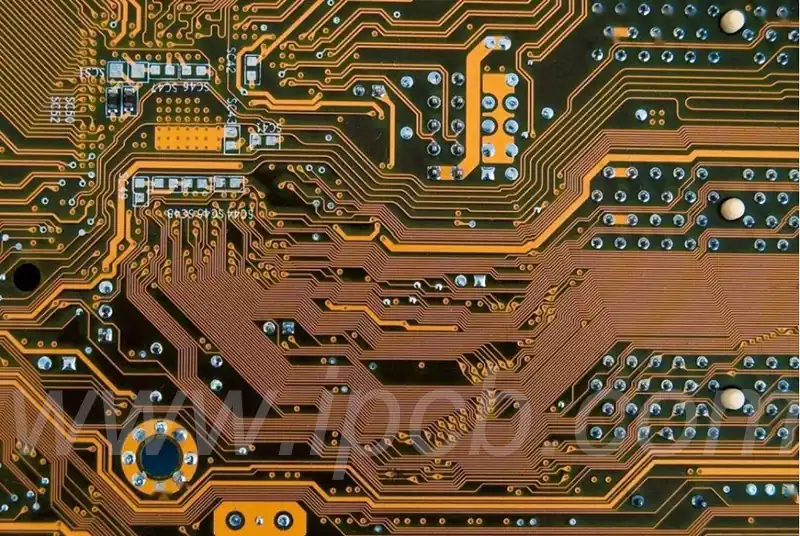

When designing a printed circuit board (PCB), following basic pcb layout rules is essential to ensure the functionality and performance of the circuit. The basic rules of PCB layout:1.According to the layout strategy of ‘major priority, complexity first’, i.e., the key unit circuits and core components should be arranged first.2.In the layout process, should refer […]