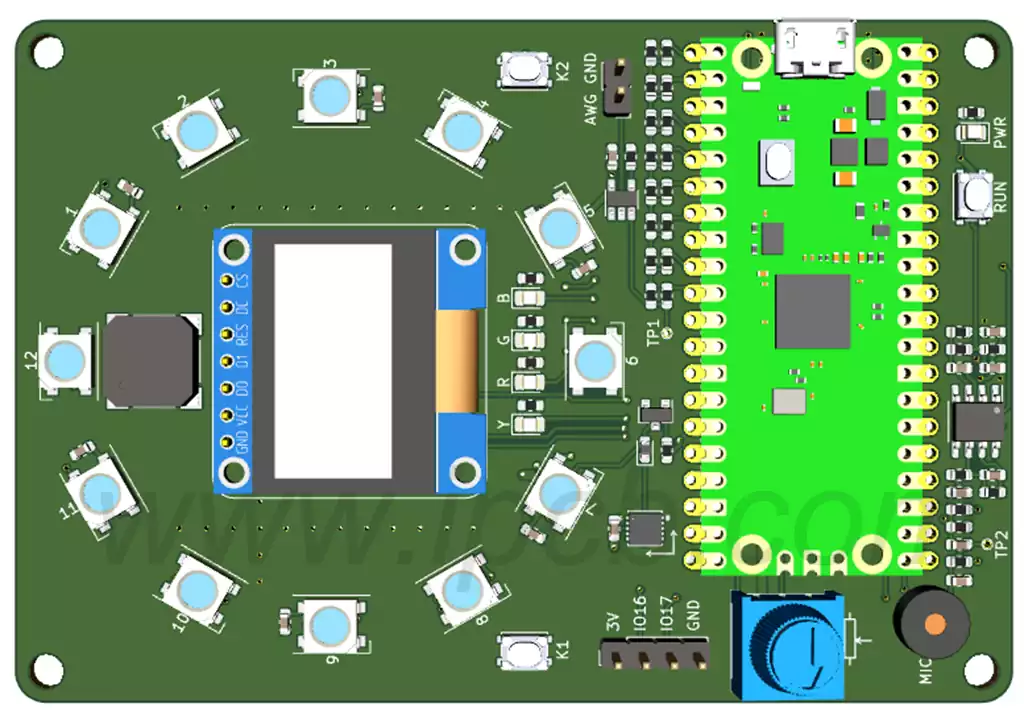

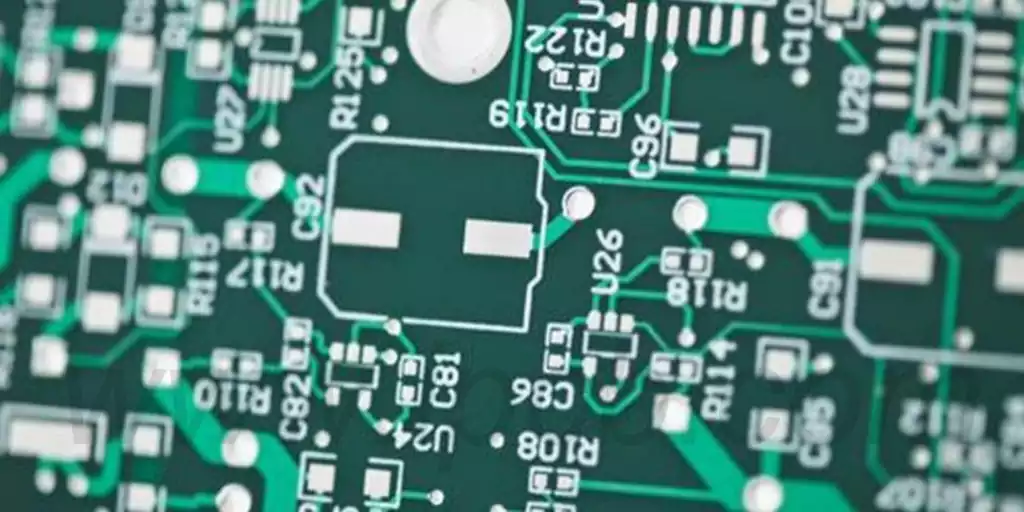

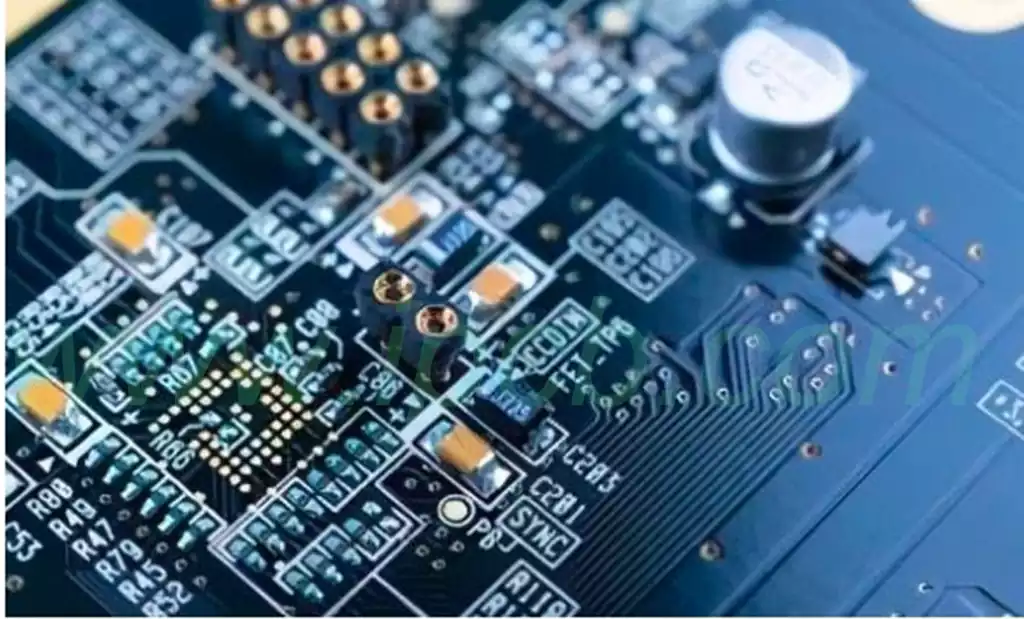

Potentiometer circuit board structure

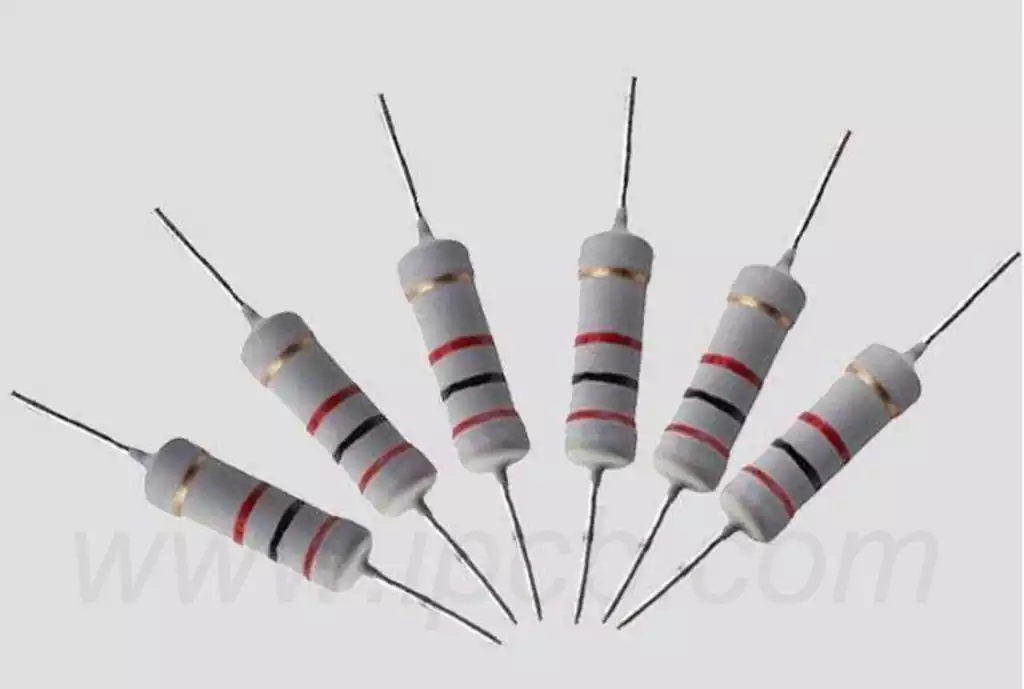

Potentiometer circuit board is circuit boards that incorporate a potentiometer, an electronic component designed to regulate and control voltage or current in a circuit. Such circuit boards are commonly used in audio equipment, lighting regulation, instrumentation, and industrial controls for precise adjustment of equipment performance. A potentiometer usually consists of three terminals, two of which […]