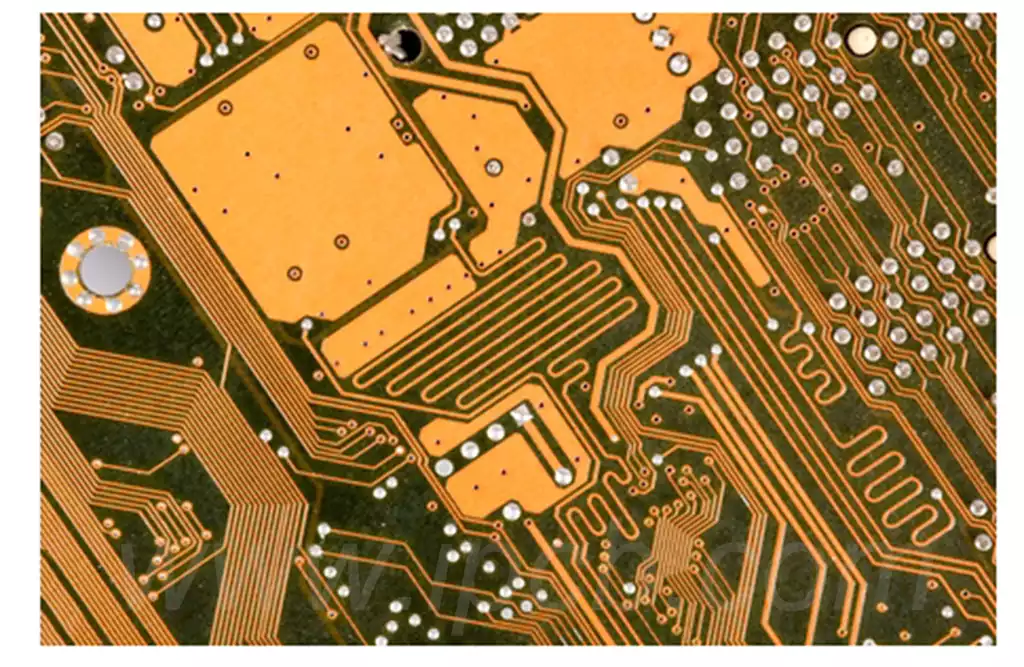

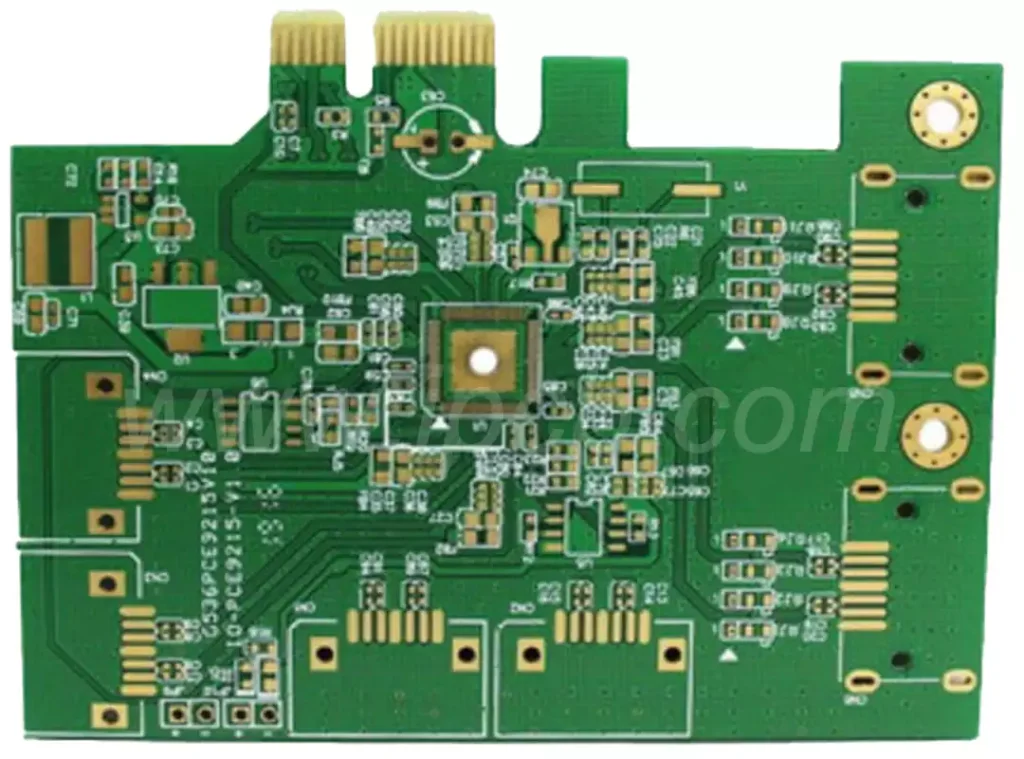

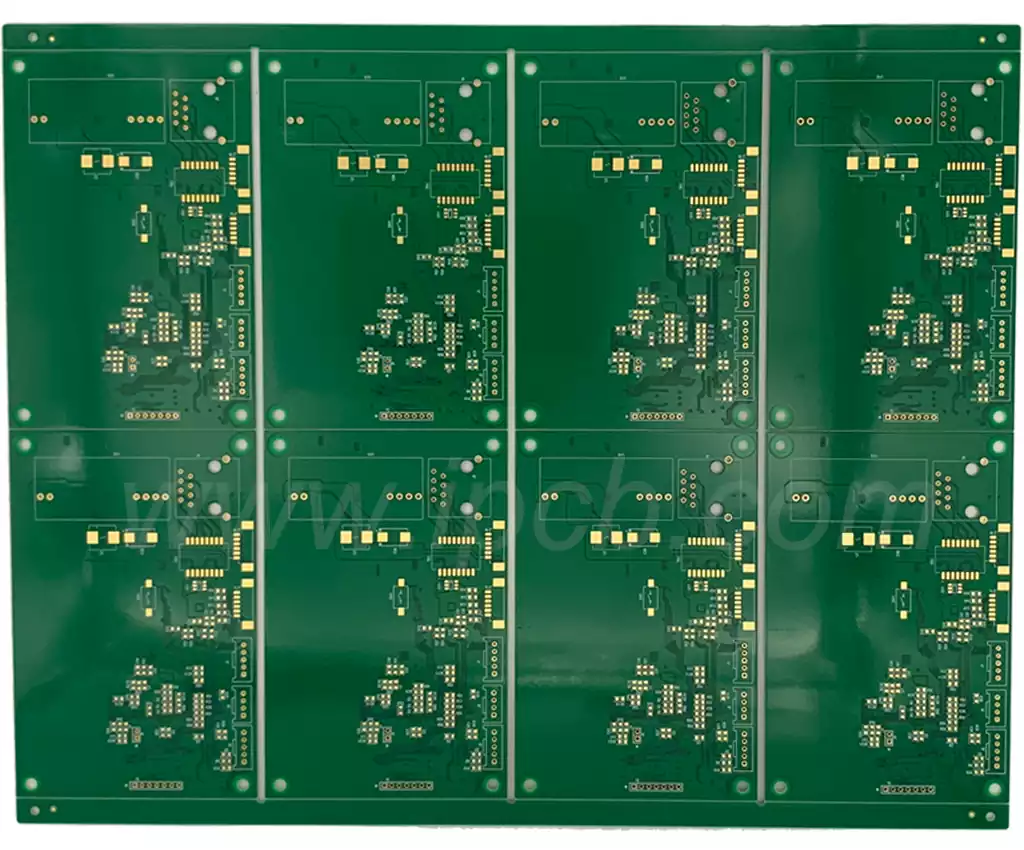

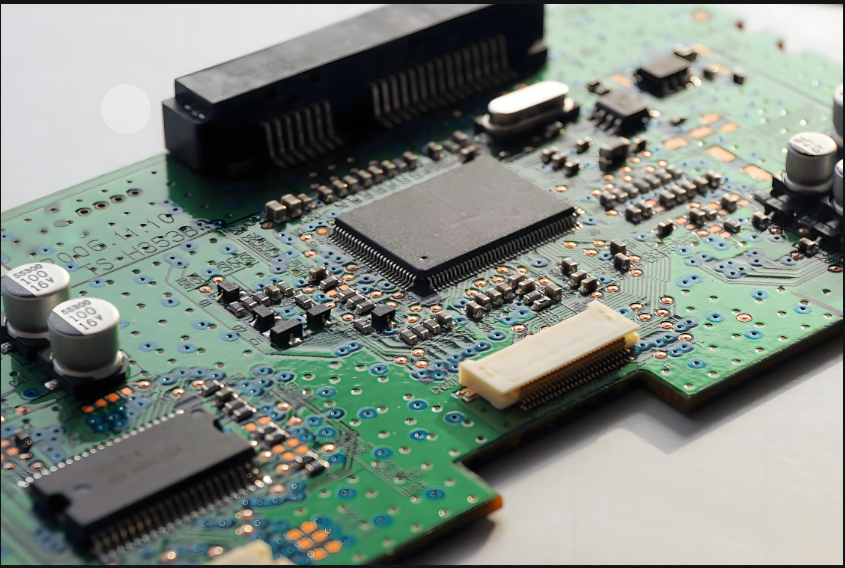

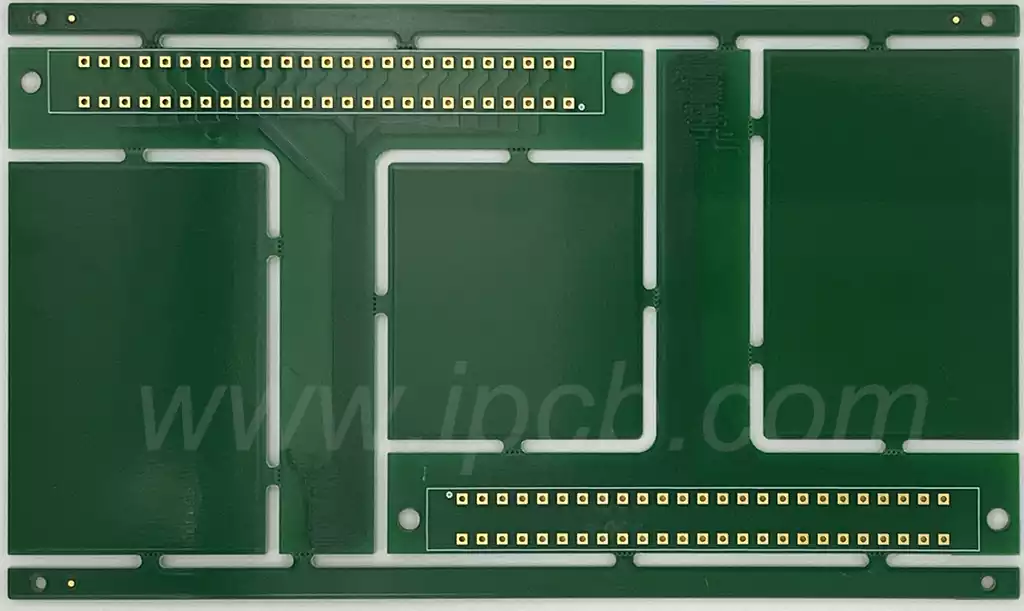

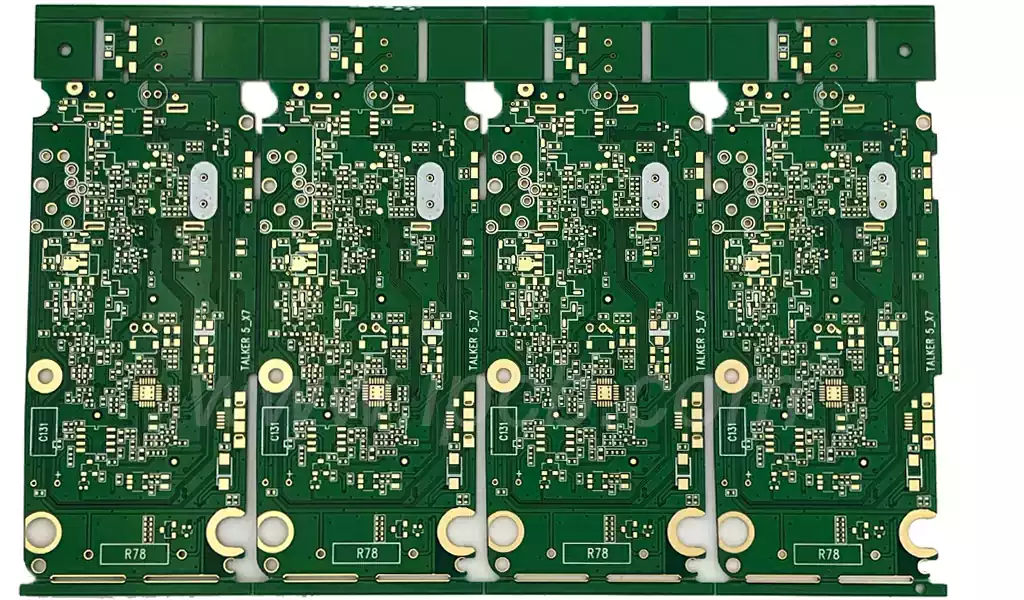

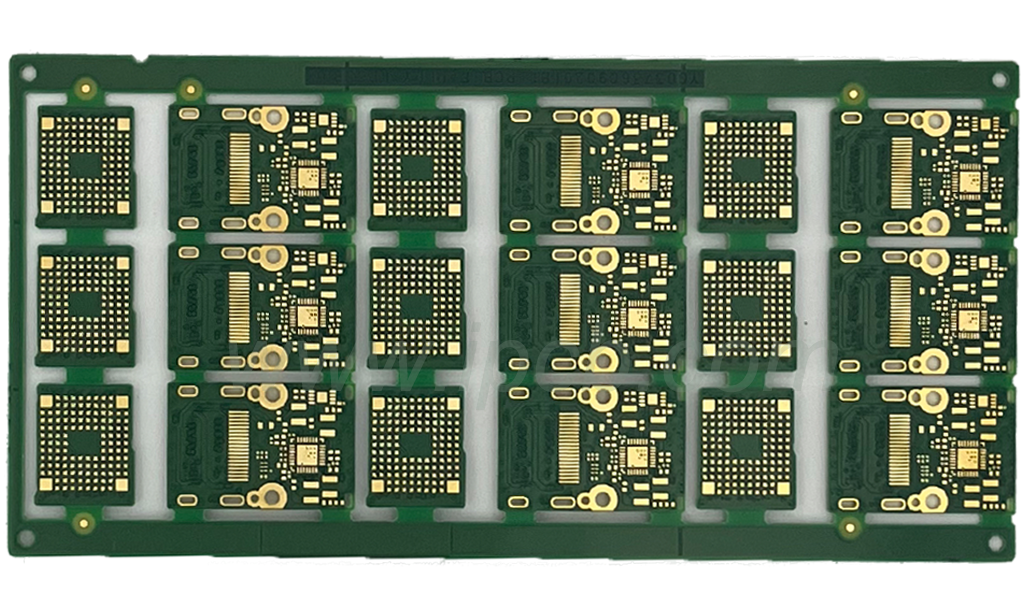

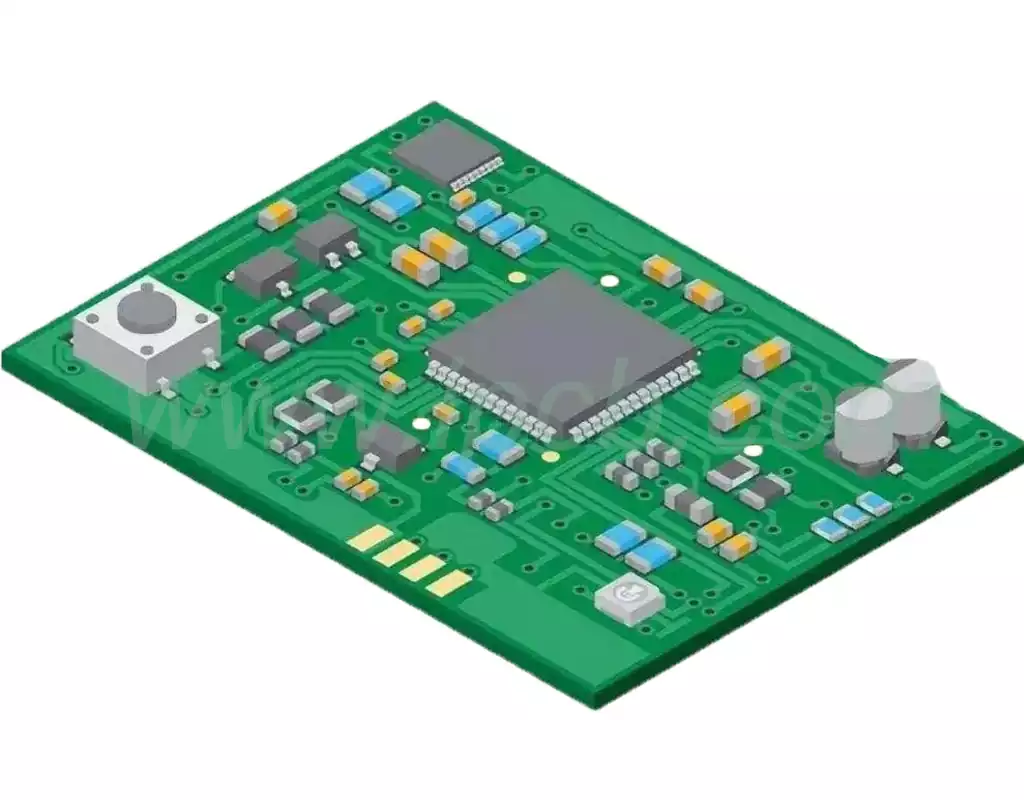

PCB Via fill and PCB Manufacturing

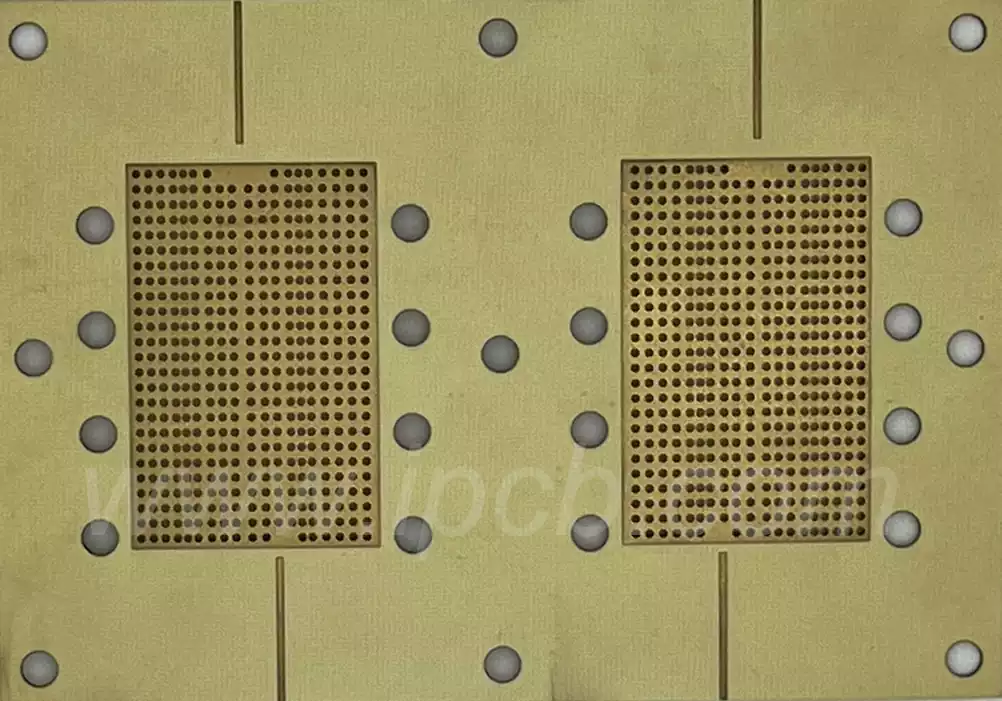

PCB Via fill is a material used to fill through holes in a PCB board. Through holes are holes punched in a PCB to connect different circuit layers so that current or signals can flow through. The purpose of through-hole fillers is to prevent liquid solder pads or other impurities from remaining in the through-holes, […]