Key Techniques for RF Circuit Board Design Interference Resistance

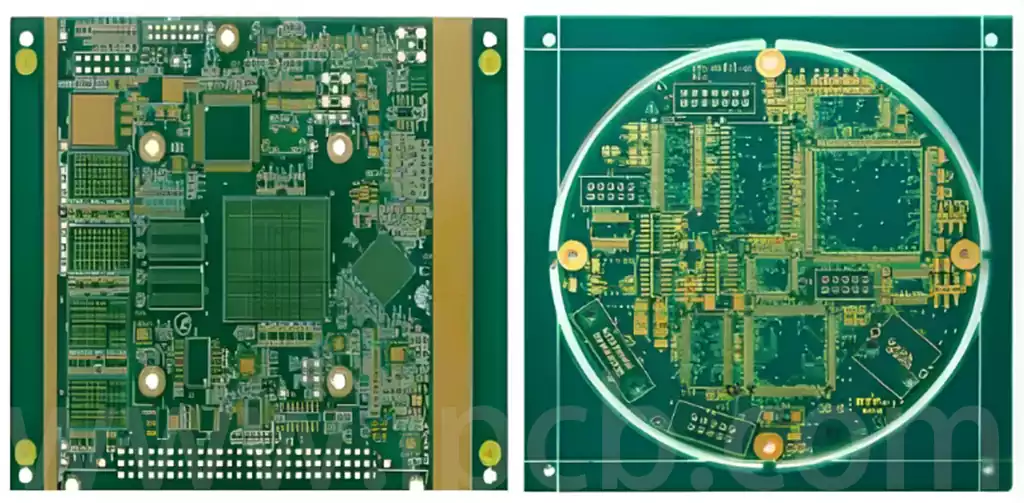

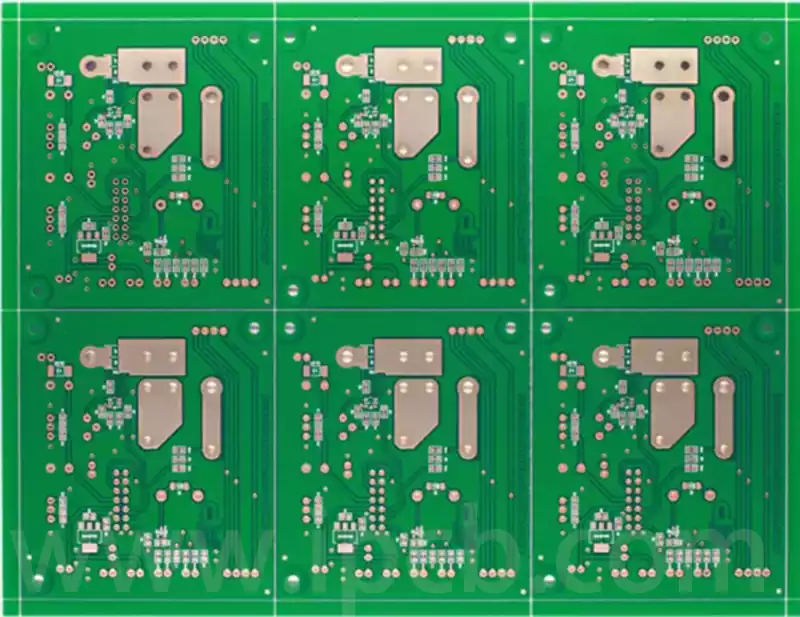

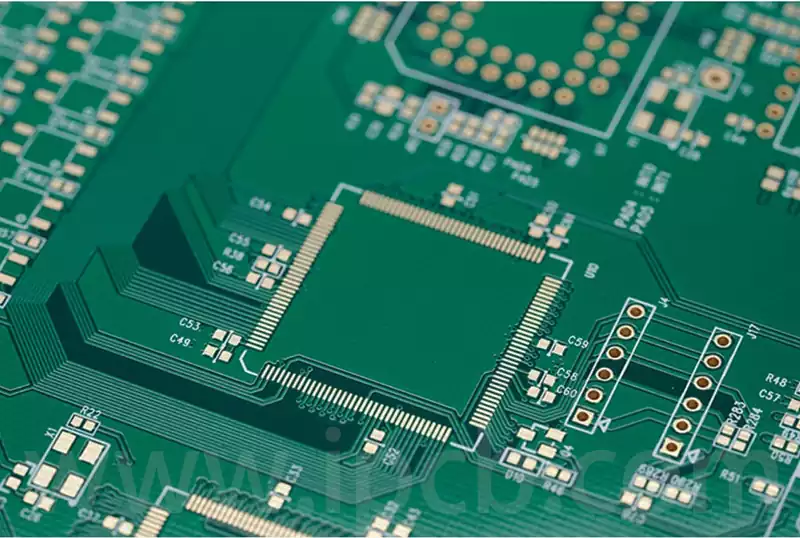

As a core component of electronic devices, the performance stability of RF circuit boards directly affects the overall operational effectiveness of the device. However, in complex electromagnetic environments, RF circuit boards are highly susceptible to various forms of electromagnetic interference, which can lead to performance degradation or even failure. Therefore, implementing effective shielding measures to […]