PCB Dielectric Thickness Analysis

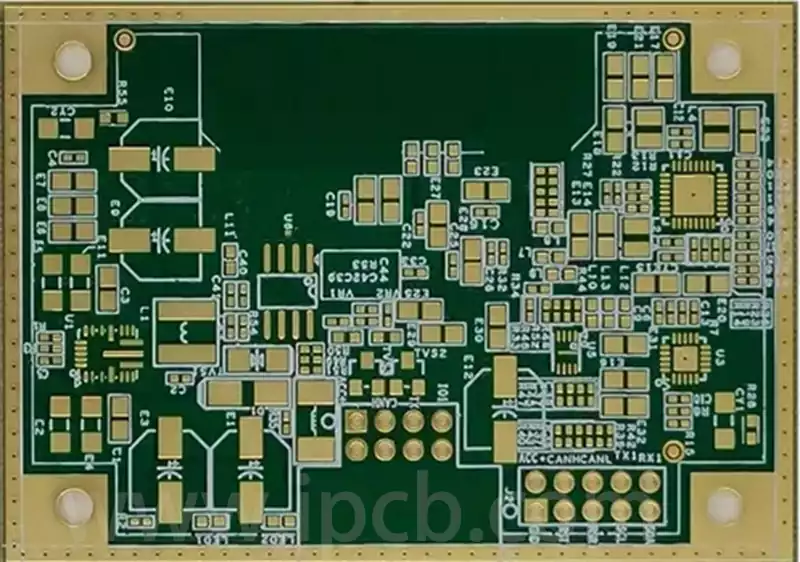

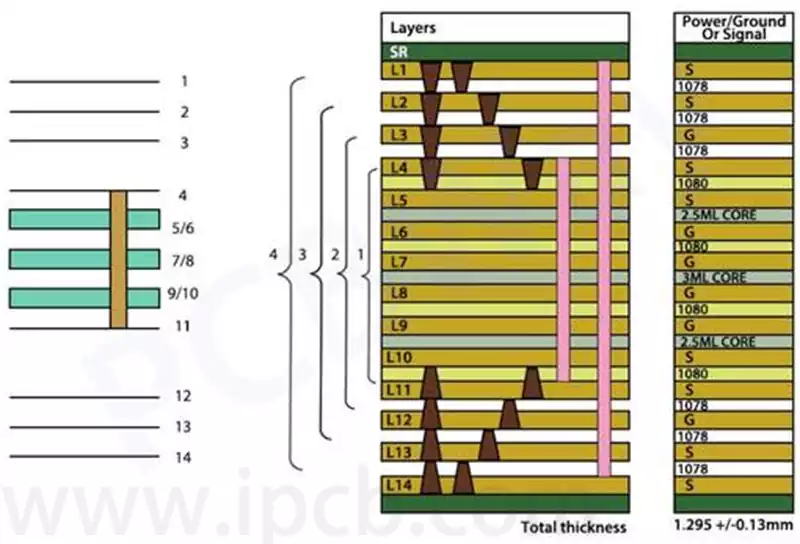

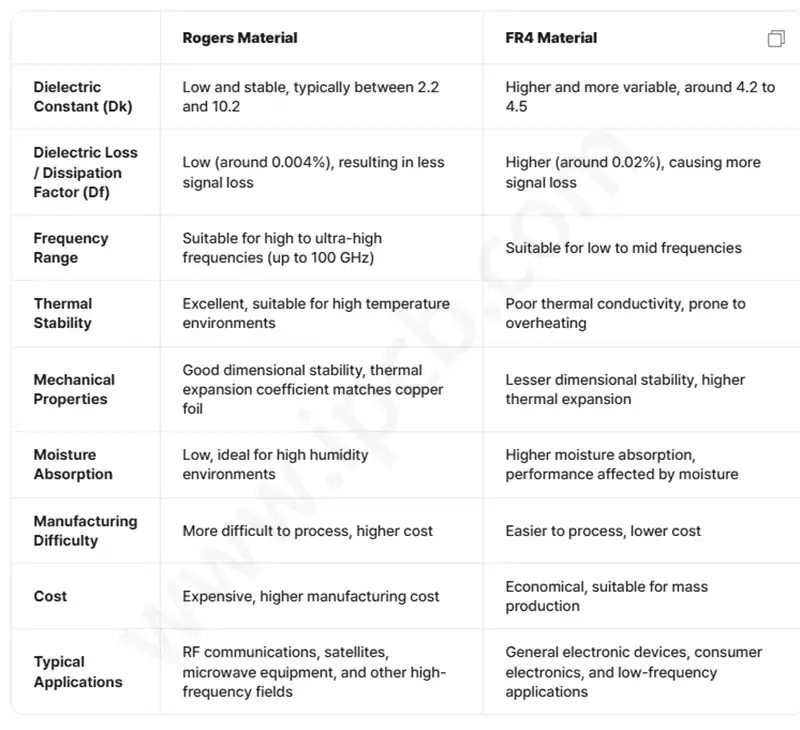

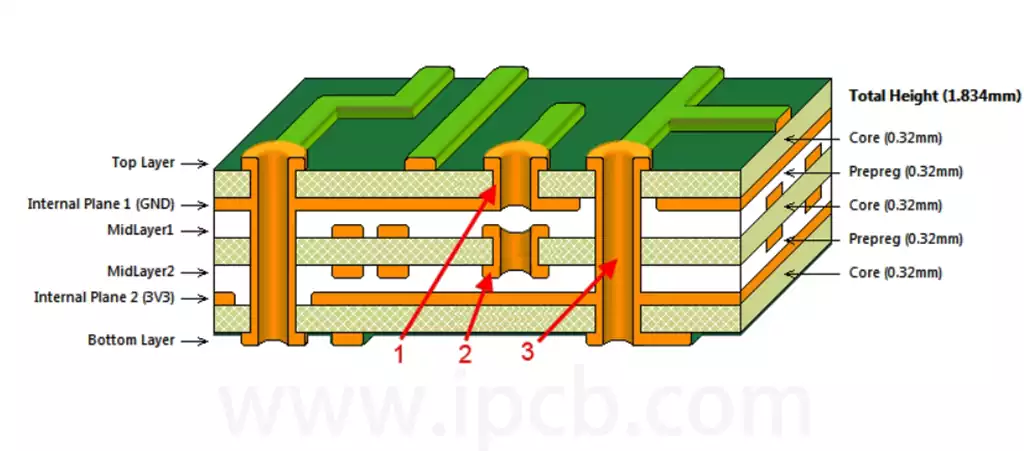

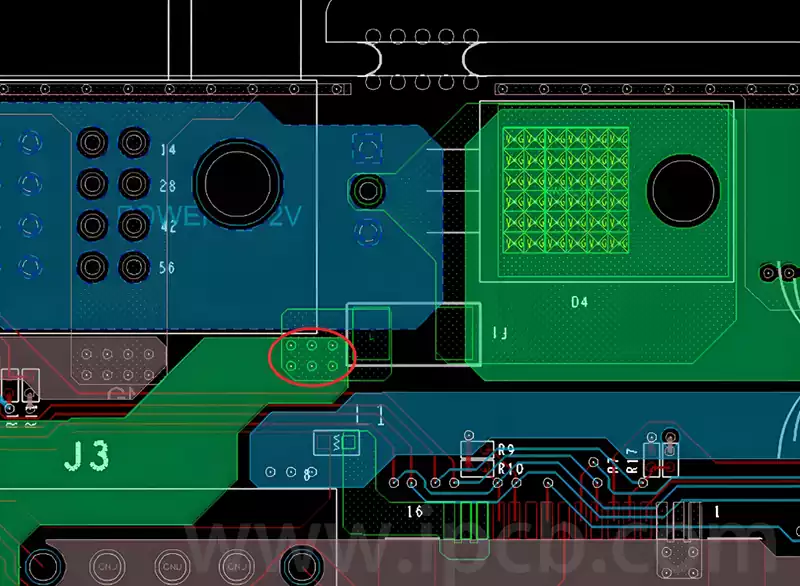

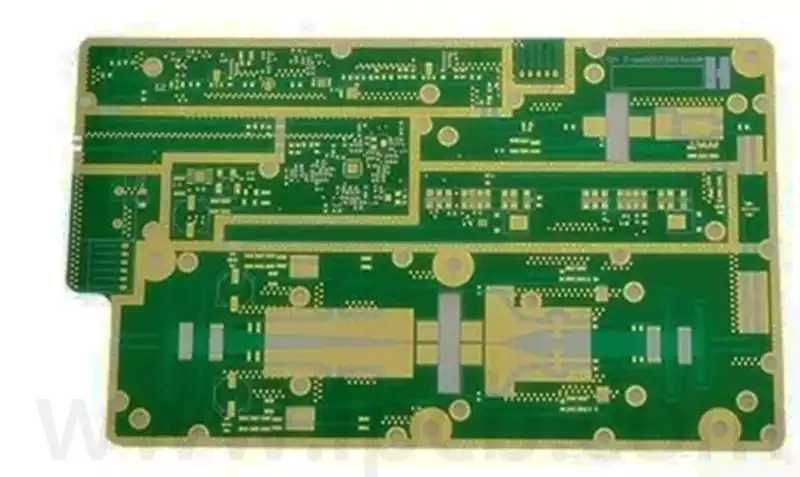

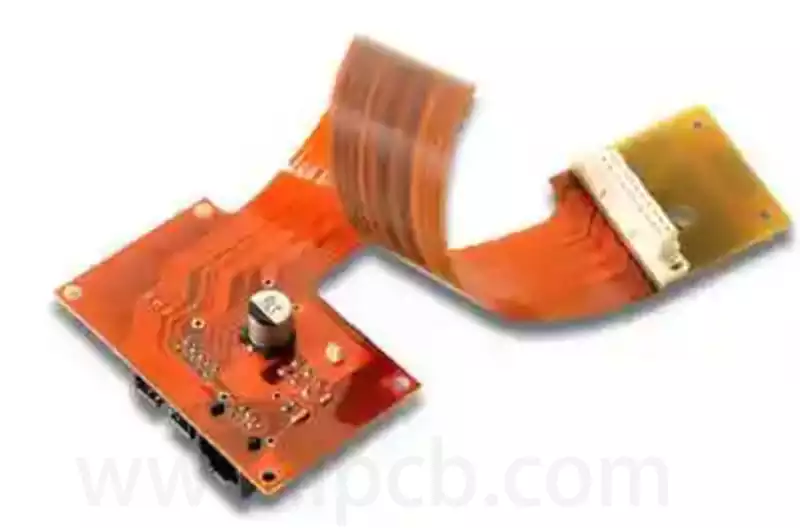

PCB dielectric thickness is usually the thickness of the glass fibre cloth or other special material used to cover both sides of a printed circuit board (PCB) during the manufacturing process. The choice of dielectric thickness depends on the specific application scenario and requirements of the circuit board. Multilayer board dielectric thickness refers to the […]