Why FR4 Plate Keyboards Are Gaining Popularity in Custom Mechanical Designs

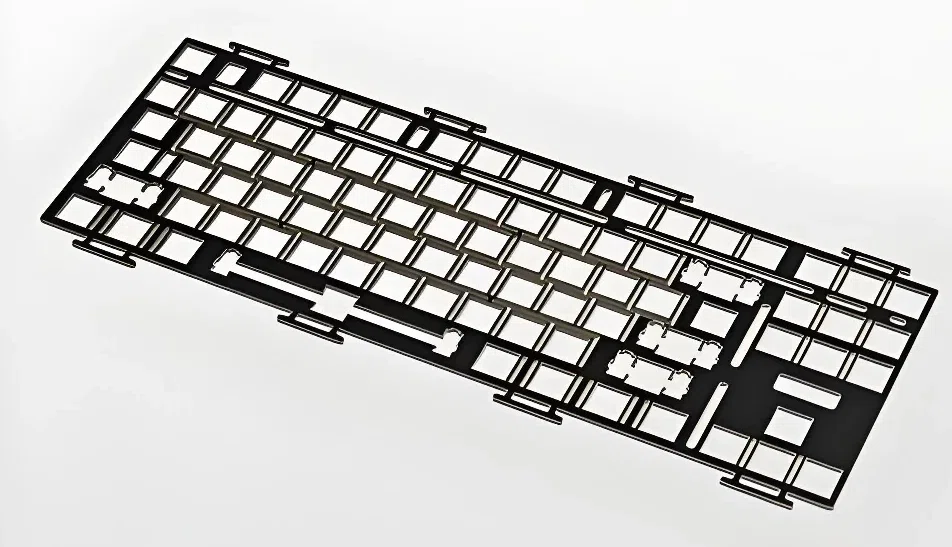

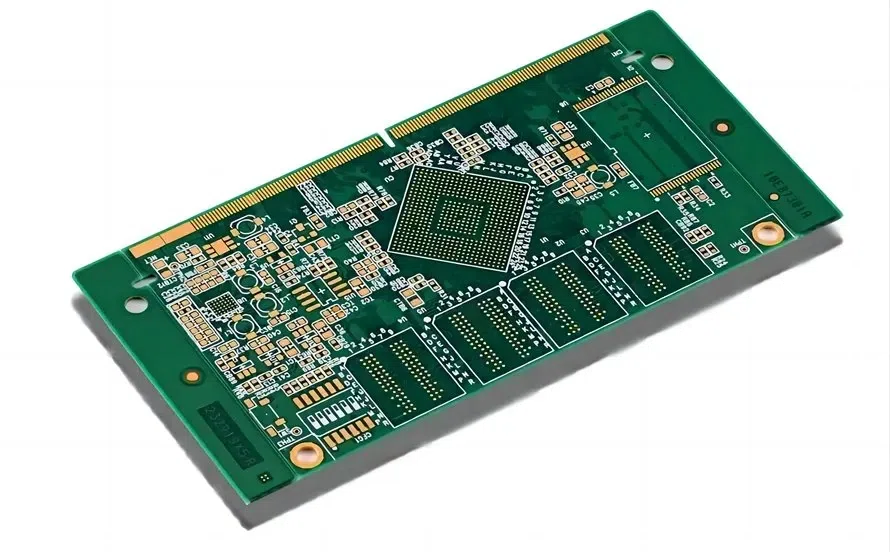

The Role of FR4 Plate Keyboard in Mechanical Keyboard Structure In the structural design of mechanical keyboards, the plate (positioning plate) is a crucial intermediate layer connecting the switches to the PCB. Its material selection directly impacts the overall feel, sound characteristics, and structural stability of the keyboard. In recent years, FR4 plate keyboards have […]