Applications and Challenges of BGA PCB Board

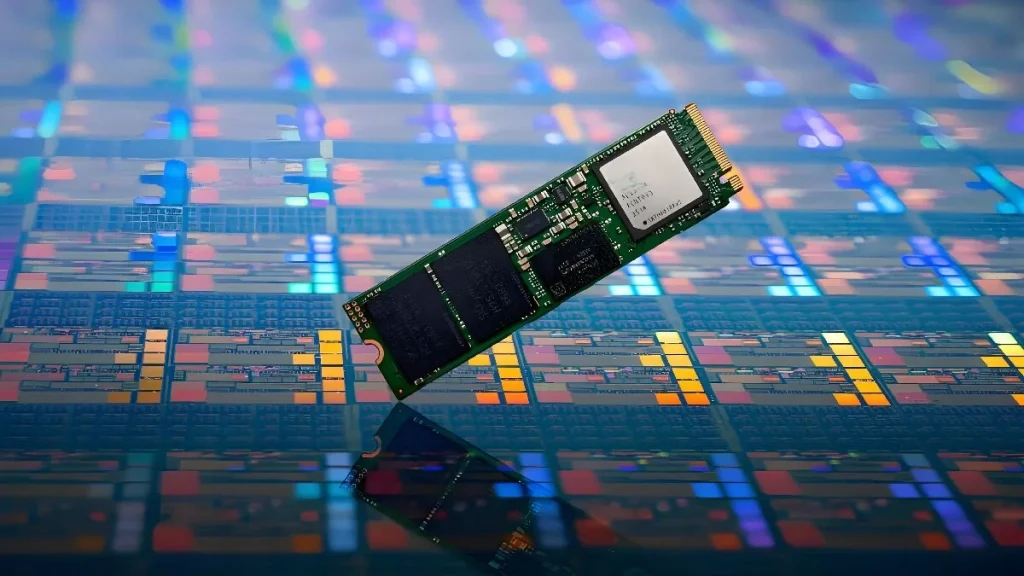

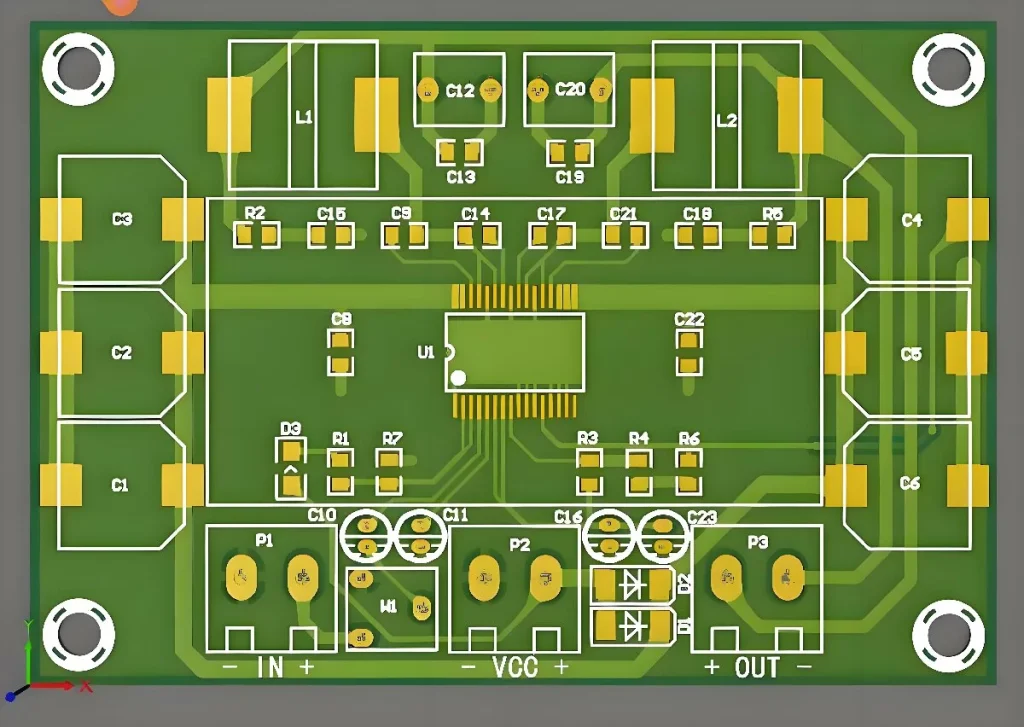

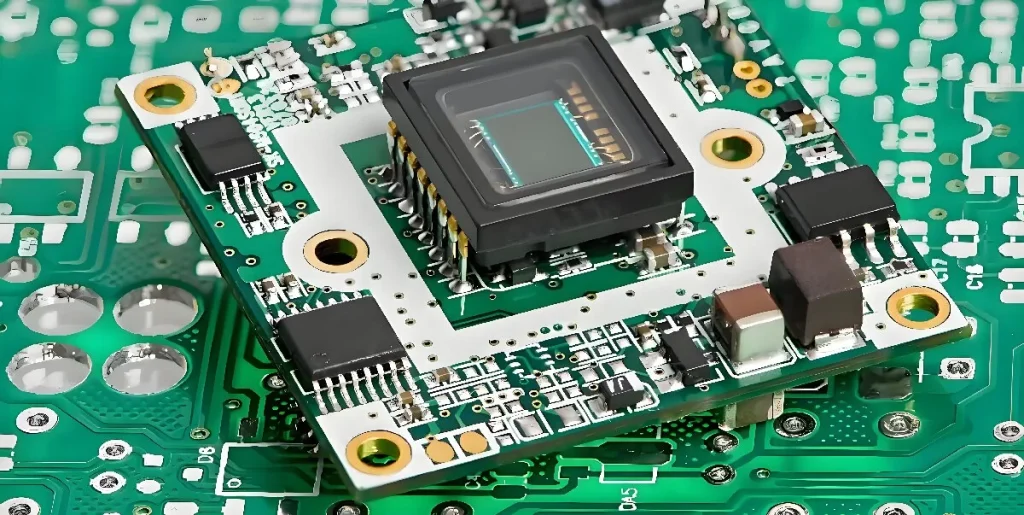

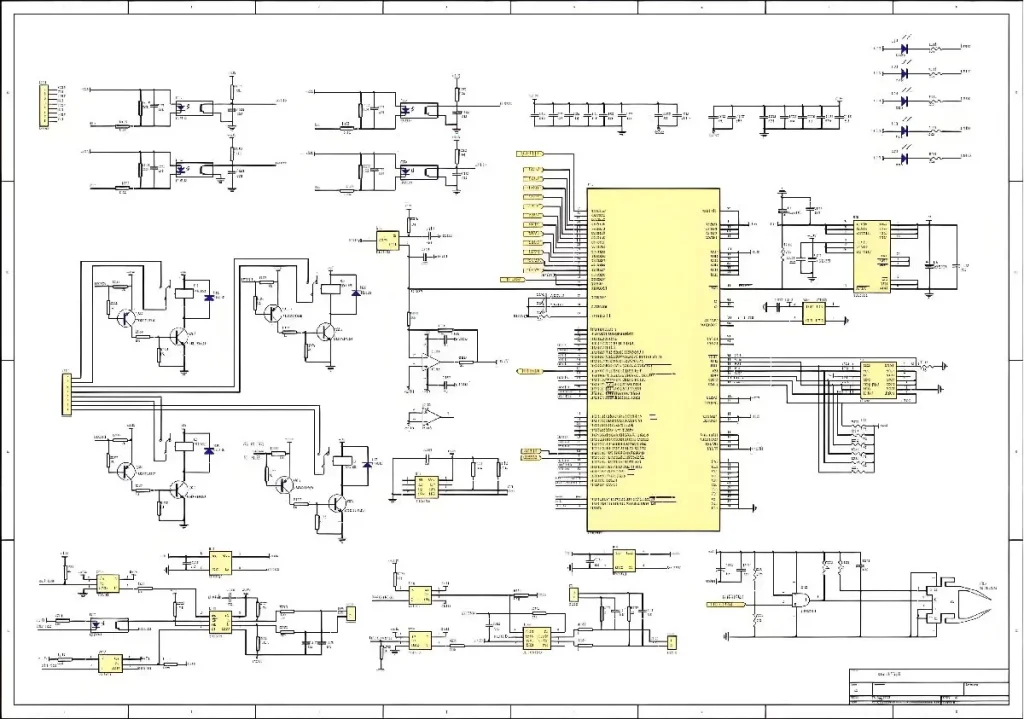

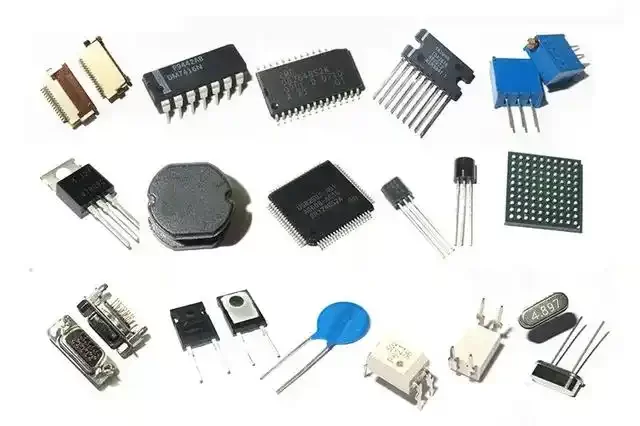

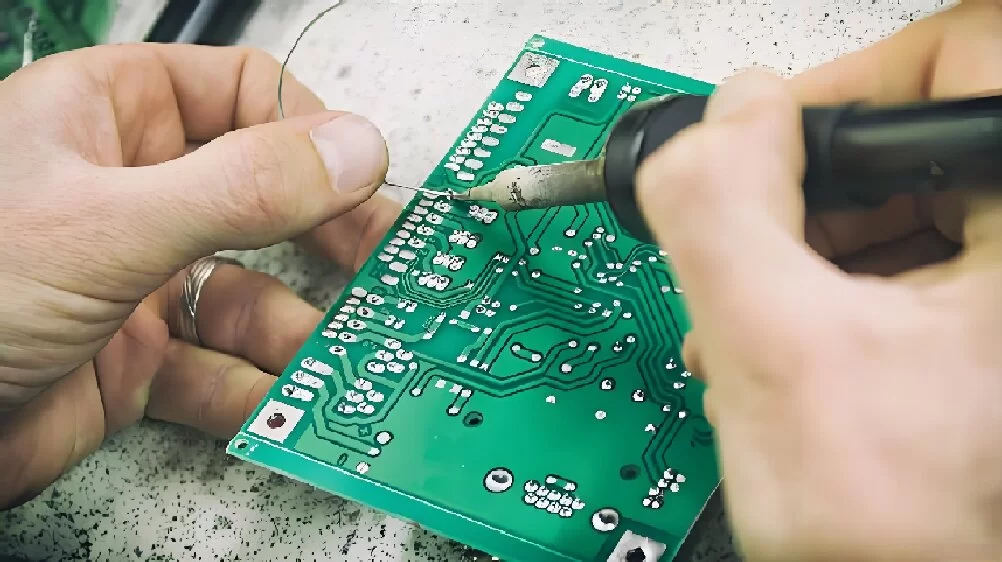

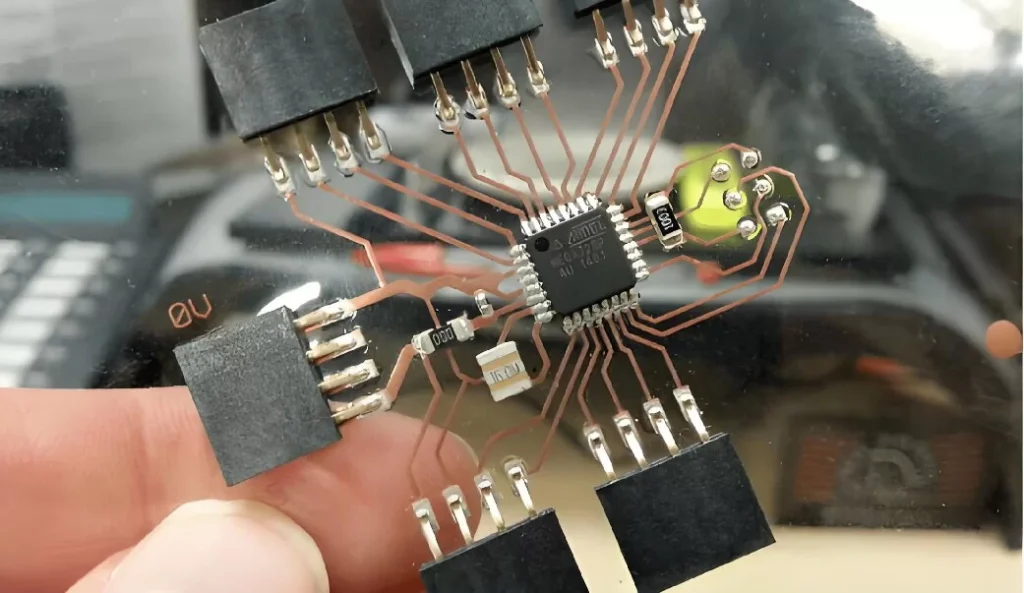

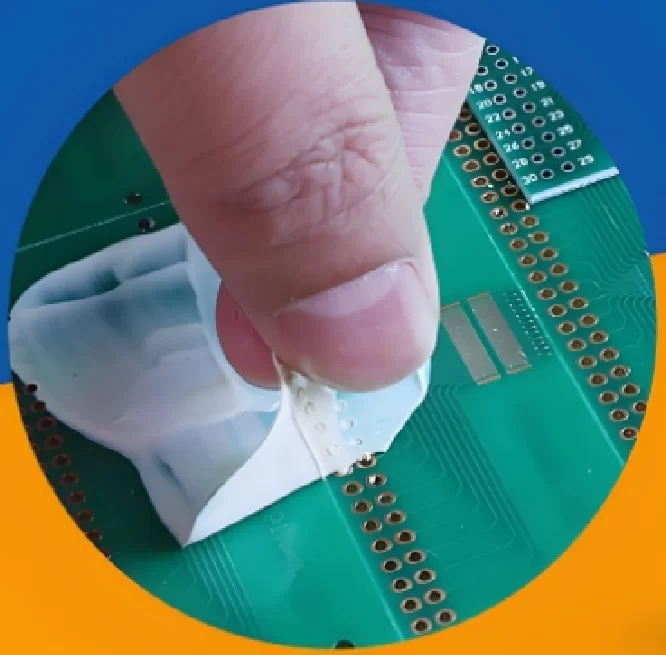

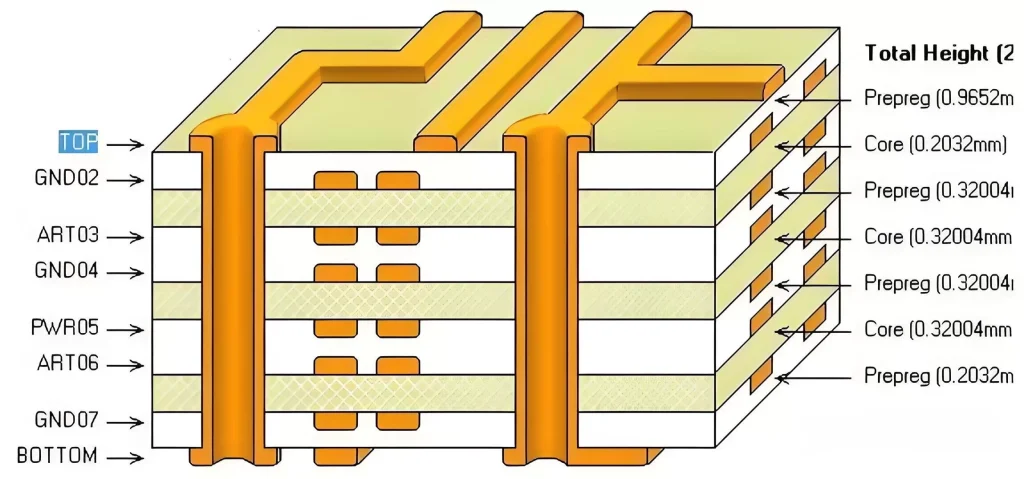

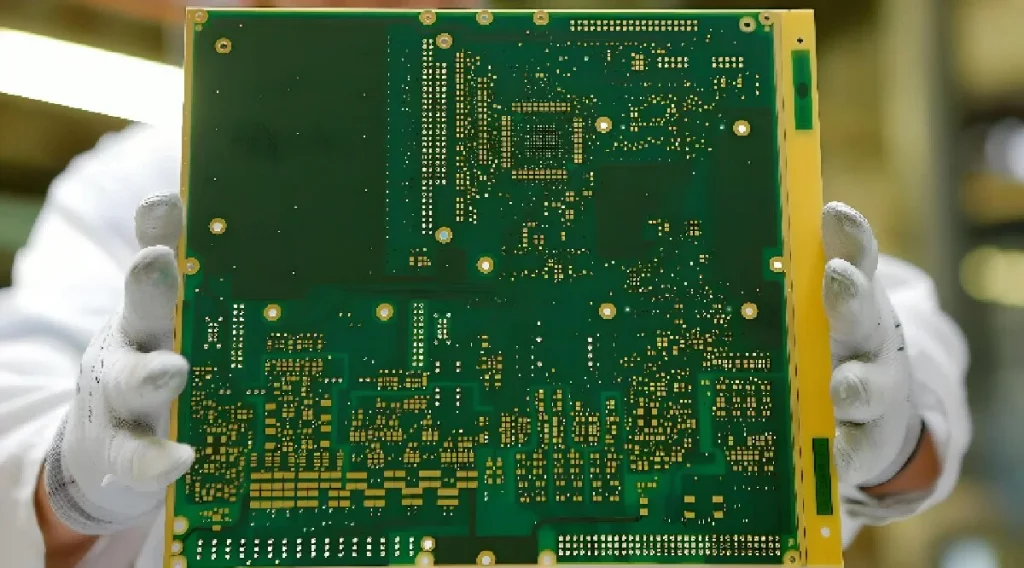

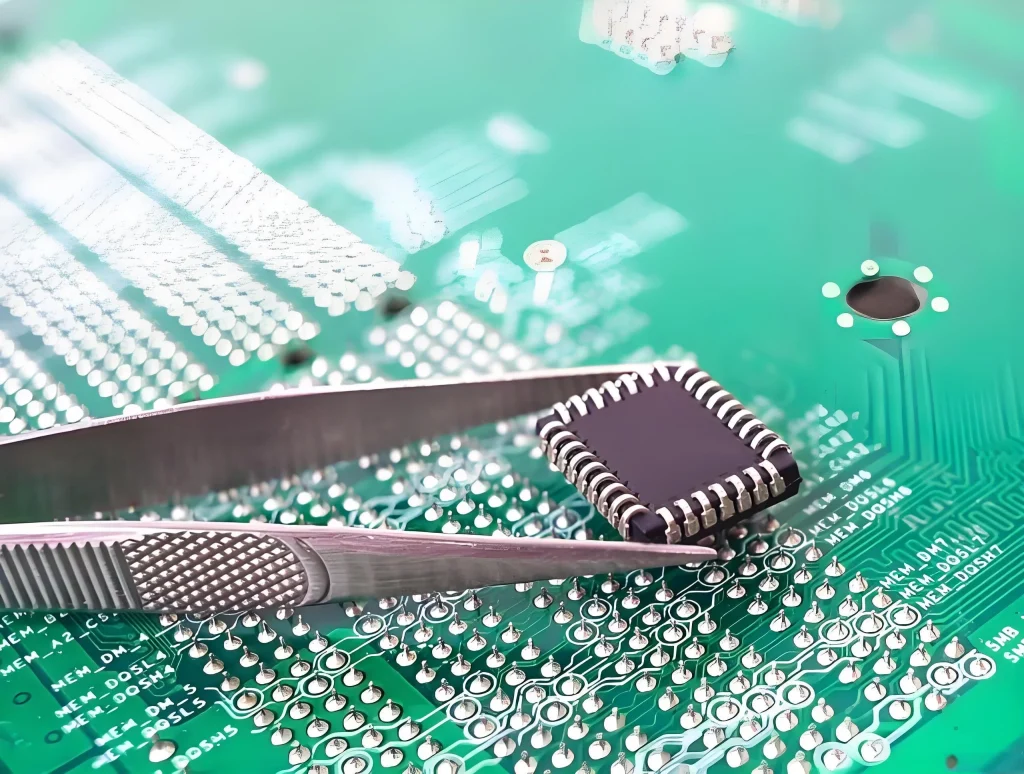

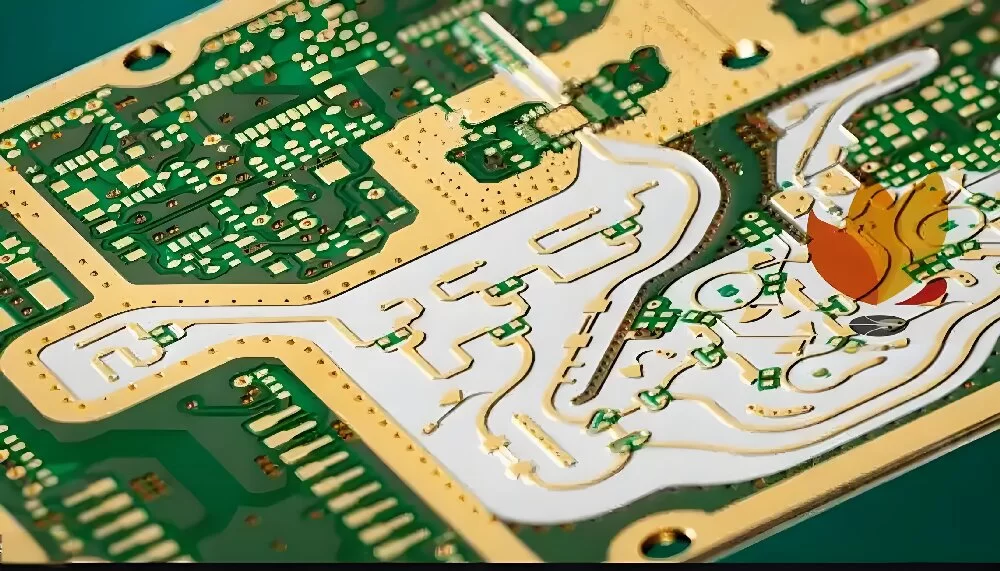

As electronic devices continue to develop towards miniaturization, high performance and low power consumption, BGA (Ball Grid Array) circuit board technology has gradually become an important part of modern electronic products.As an advanced integrated circuit packaging technology, BGA packaging has the advantage of providing higher integration and better heat dissipation performance, and is widely used […]