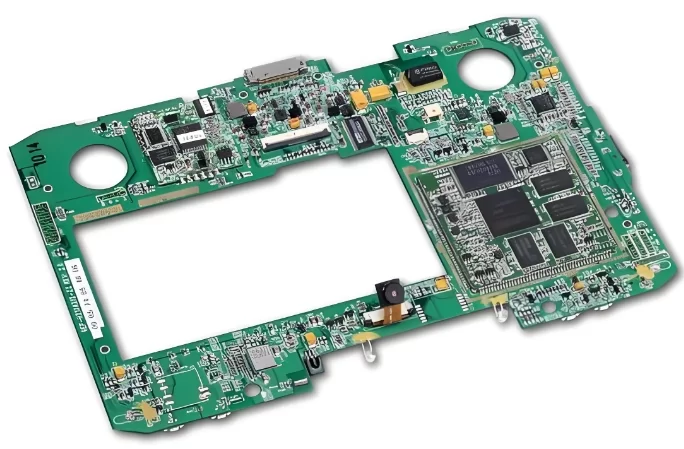

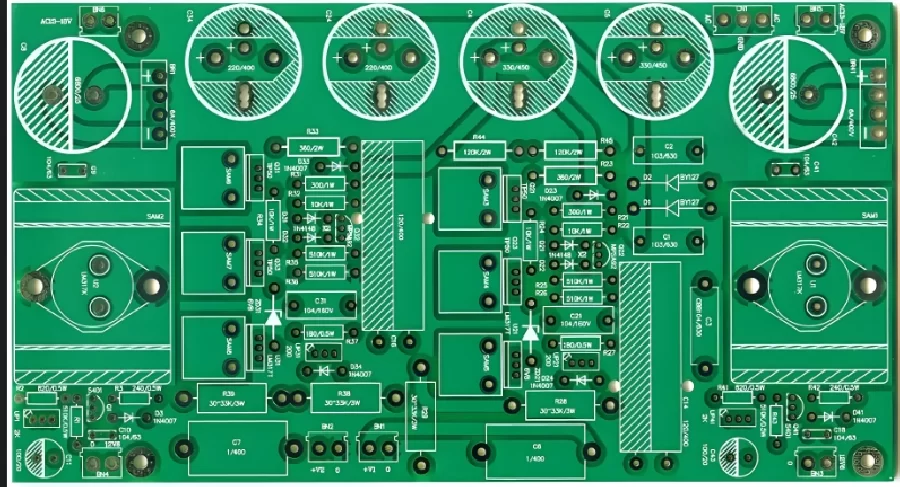

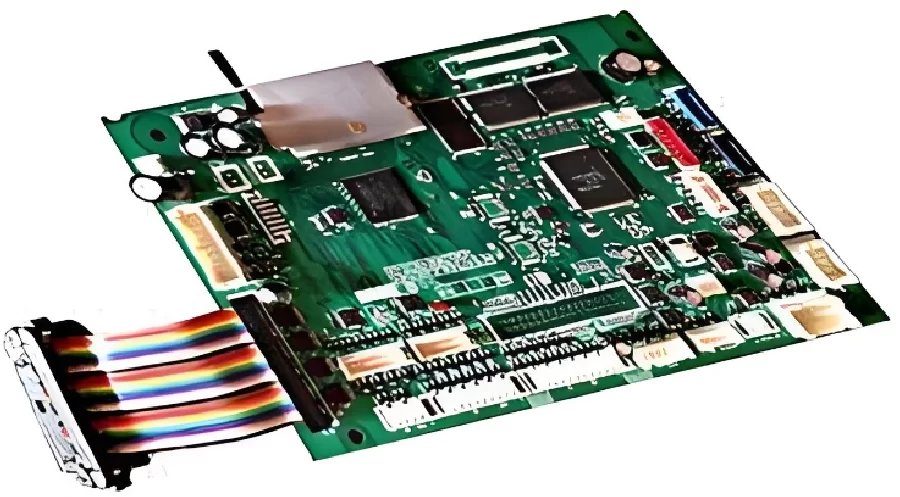

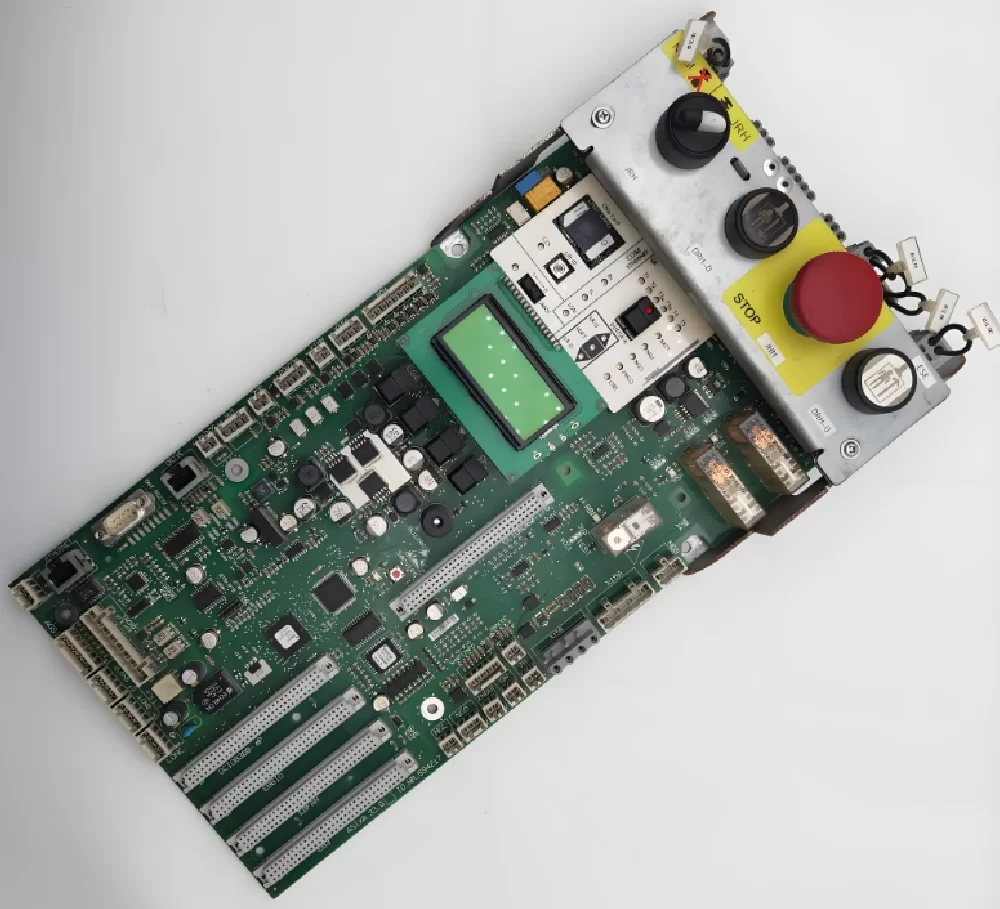

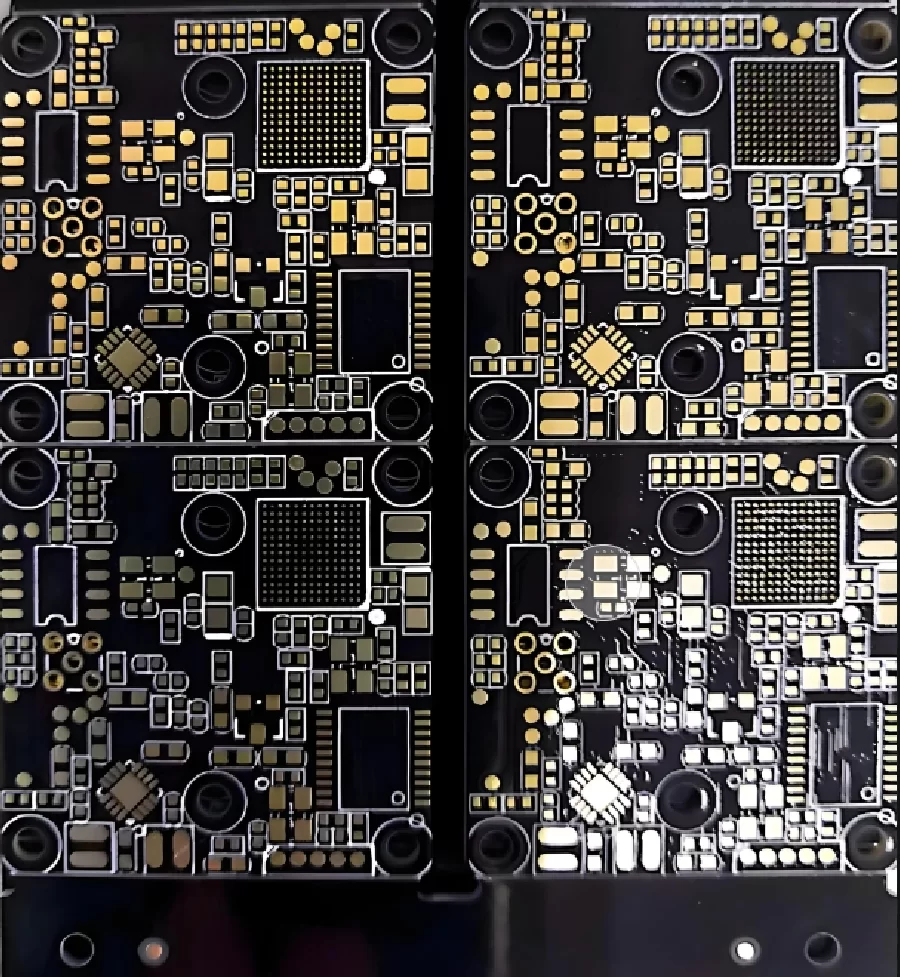

Automotive Printed Circuit Board Repair

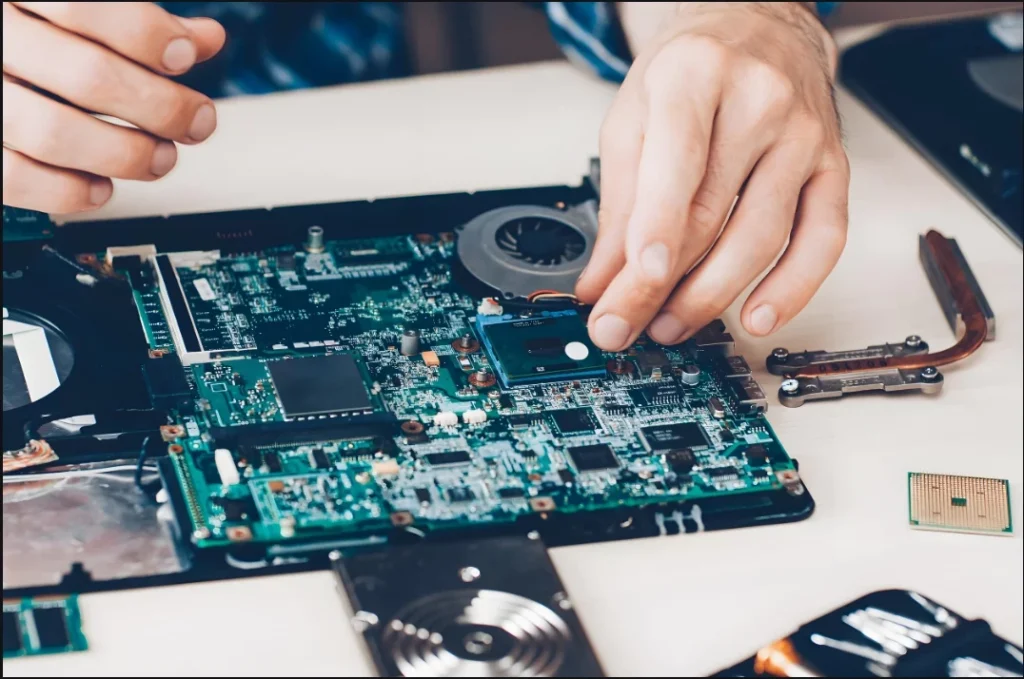

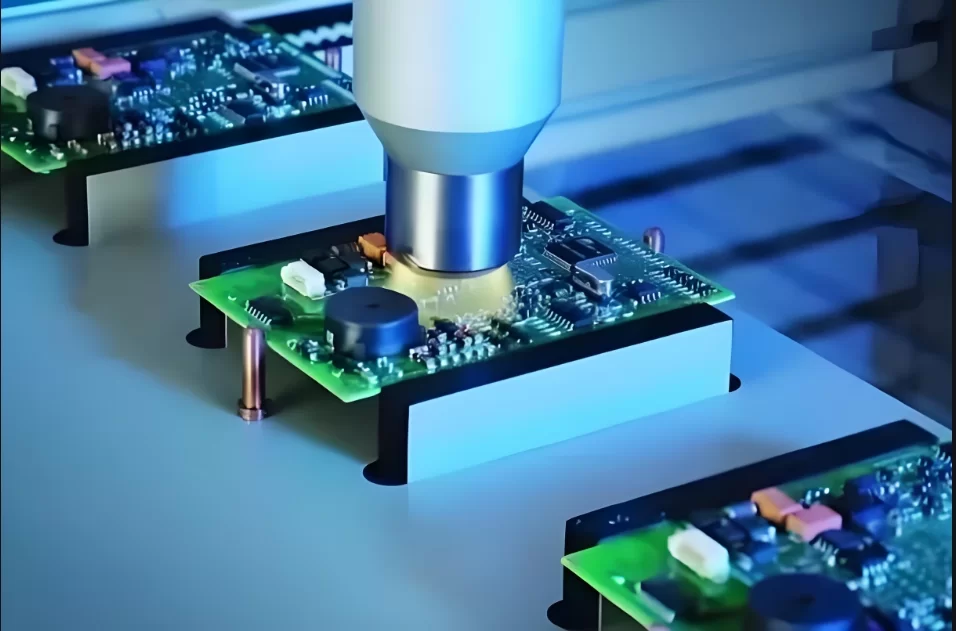

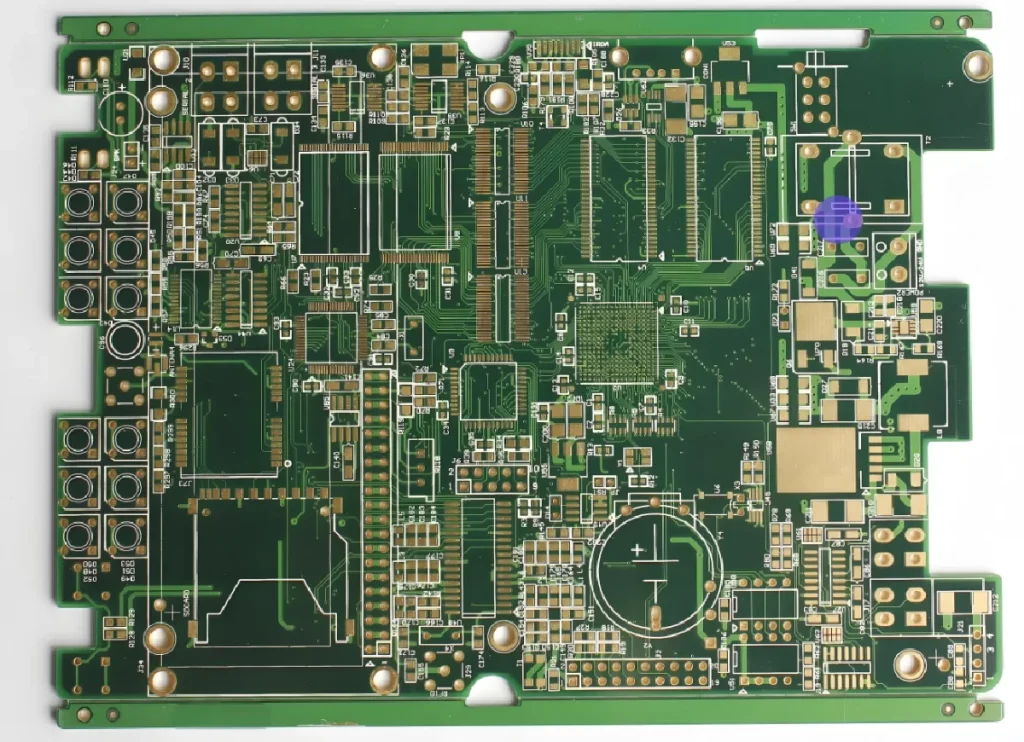

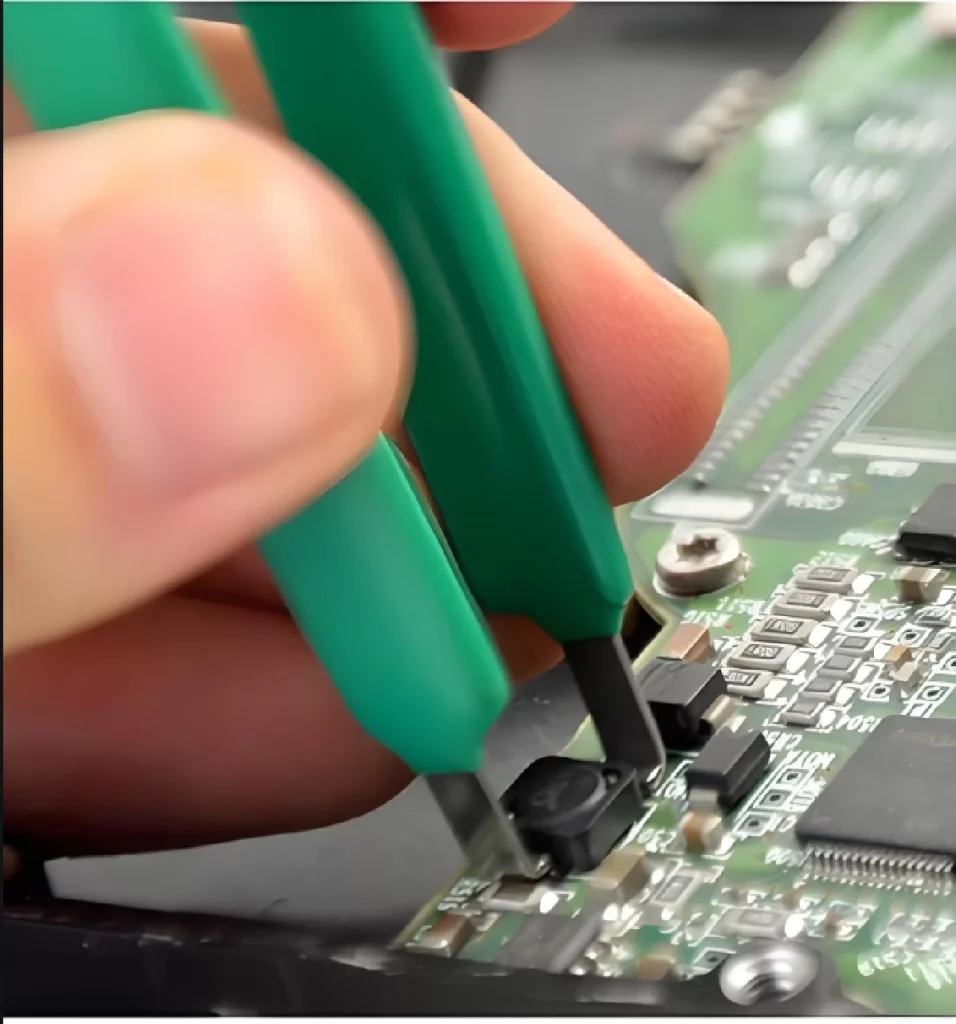

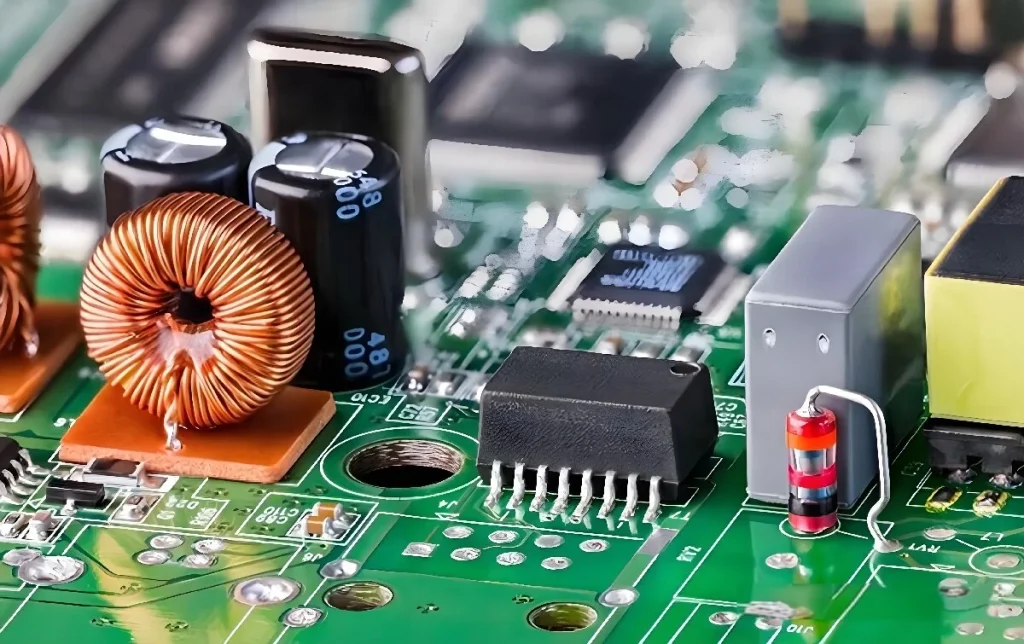

Introduction With the continuous progress of automobile technology, the electronic systems in automobiles are becoming more and more complex. The role of printed circuit boards (PCBs) as a core component of automotive electronic systems is crucial. Whether it is the power system, infotainment system or safety control system, PCB plays an indispensable role. However, with […]