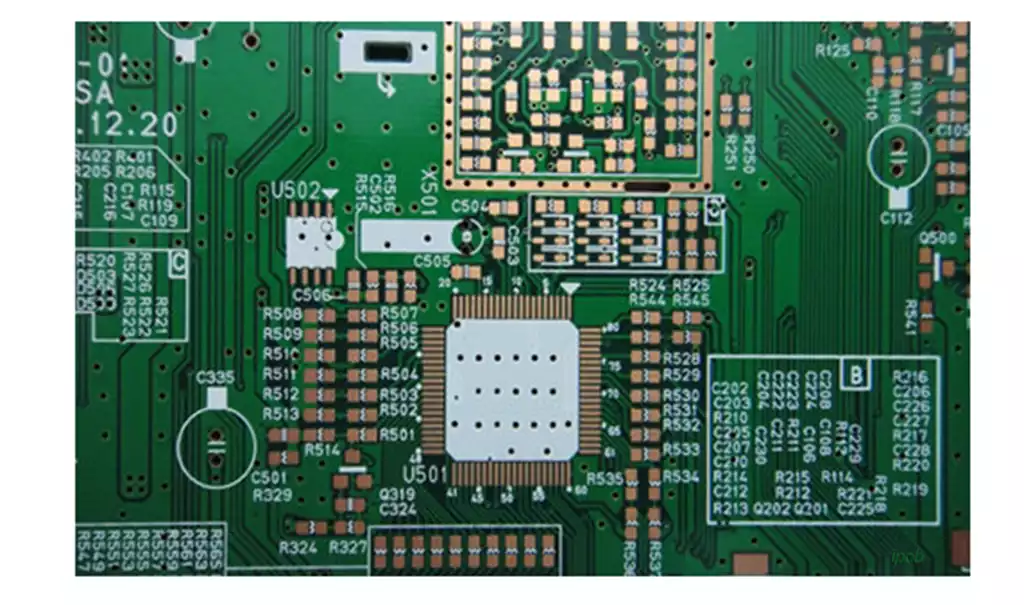

As the core component of automotive electronic system, the manufacturing quality of automotive circuit board (PCBA) is directly related to the performance and safety of the whole vehicle. Due to the complexity of the automotive operating environment, PCBA production needs to meet the high reliability, high temperature resistance, vibration resistance and other stringent requirements. In this article, we will analyse the processing flow and key manufacturing details of automotive circuit boards PCBA.

Automotive circuit board PCBA processing process:

- Raw material preparation

Circuit board substrate procurement: first of all, according to the special requirements of automotive electronics, select the appropriate circuit board substrate. Due to the harsh environment inside the car, temperature fluctuations, vibration and the existence of electromagnetic interference, usually choose a high heat resistance, high mechanical strength, good electromagnetic compatibility of the substrate, such as special modification of the FR-4 plate or high-performance flexible board. These substrates need to meet strict industry standards to ensure stable operation under complex working conditions.

Selection and procurement of electronic components: According to the design of automotive electronic circuits, we accurately screen all kinds of electronic components, including resistors, capacitors, inductors, chips, etc. The quality of components has a direct impact on the quality of the PCBA. The quality of components directly affects the quality of PCBA, so we must use products that meet automotive-grade standards, with high reliability, wide temperature range adaptability and other characteristics. For example, the chip in the automotive engine control system needs to be able to operate accurately at extreme temperatures from -40℃ to 125℃ to ensure stable engine control. Procurement back to the components need to go through a strict factory inspection, check the integrity of the appearance, the accuracy of the electrical parameters, etc., to prevent defective products into the production line.

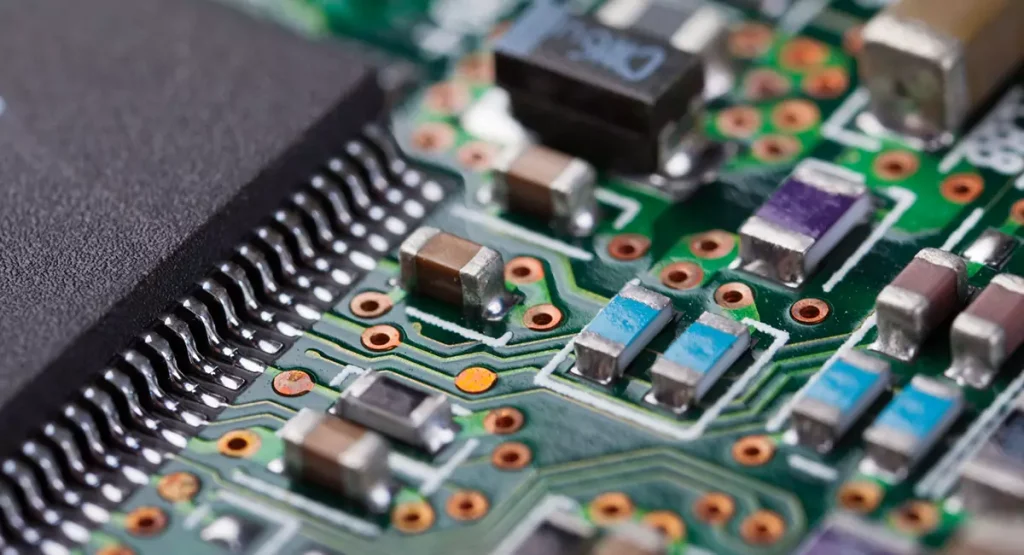

2.SMT chip processing

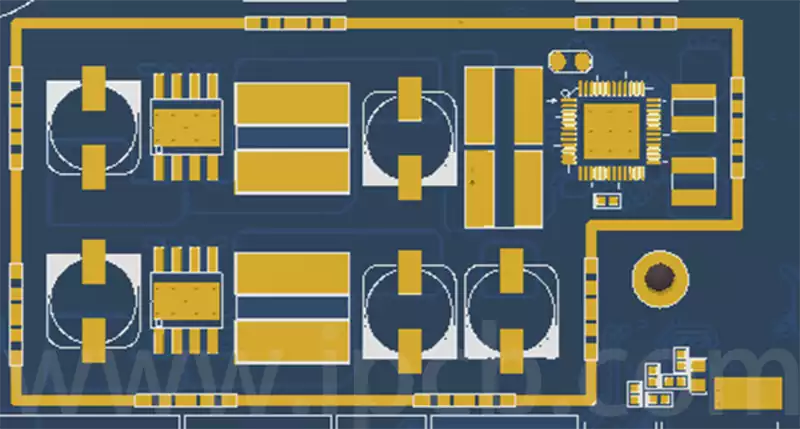

Solder Paste Printing: The carefully formulated solder paste is uniformly printed onto the pads of the circuit board through the stencil. Automotive electronics PCBA on the solder paste printing precision requirements are extremely high, because the slightest deviation may lead to subsequent welding defects, affecting circuit performance. Stencils are usually made by high-precision laser cutting or etching processes, and different mesh sizes and shapes are designed for the pads of different components to ensure that the amount of solder paste is just right. For example, for 0201 and other tiny package components, the mesh is correspondingly small to control the amount of solder paste to prevent short-circuiting; for BGA package chips and other large-area pads, the mesh is larger to ensure that sufficient solder paste to achieve reliable soldering.

SMD: The use of high-precision SMD machines to quickly and accurately mount electronic components to the pads printed with solder paste. The mounter accurately identifies the location of the component and picks up and places it according to a preset programme. In automotive electronics, the precision of the placement machines needs to be in the micron range to cope with the many tiny and tightly packed components on complex PCBAs such as in-car navigation systems, self-driving controllers, etc. The placement process ensures that the component pins are correctly positioned. The placement process ensures that the component pins are perfectly bonded to the solder paste, laying the foundation for subsequent soldering.

Reflow soldering: After the mounting is completed, it enters the reflow soldering process, where the solder paste is melted and solidified by heat through precise control of the temperature profile, forming a reliable solder joint. Automotive circuit board PCBA reflow temperature profile design needs to take into account a variety of factors, such as the heat resistance of different components, circuit board substrate materials. Too high a temperature may damage the components, too low to ensure the quality of the solder joints. General use of multi-temperature reflow oven, gradually warming, constant temperature, cooling, to ensure that the solder paste in the appropriate time to complete the melting and solidification process, to achieve high-quality welding.

3.THT plug-in processing (if necessary)

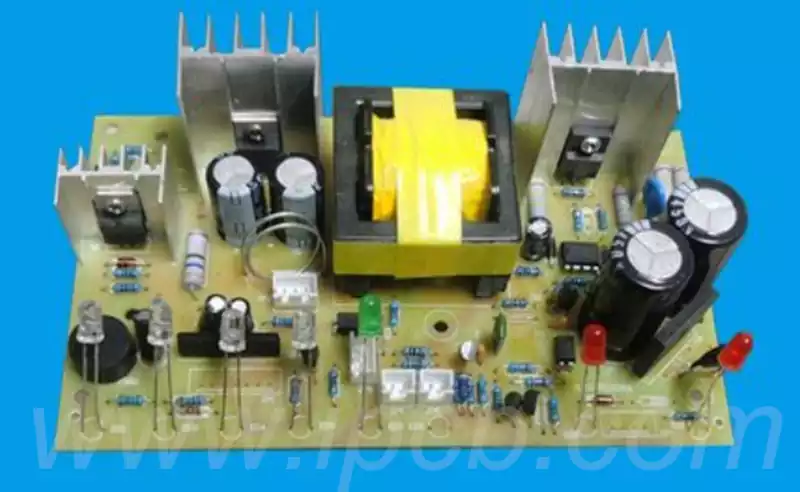

Part of the automotive circuit board PCBA also involves through-hole insertion technology (THT) processing links. For some of the larger power, high mechanical strength requirements or not applicable to SMT patch components, such as large electrolytic capacitors, relays, etc., need to use THT process.

Insertion: Workers will insert the pins of the components into the pre-drilled holes in the circuit board, requiring the insertion of the depth of the right, straight pins, to ensure a good connection with the circuit board and the inner layer of the line. This process requires manual operation combined with auxiliary tooling to ensure the accuracy and consistency of the plug-in.

Wave soldering: After the plug-in is completed, the wave soldering equipment is used for soldering. Liquid solder to form a wave-like shape, the circuit board from the wave through the peak, so that the component pins and circuit board pads fully infiltrated welding. The key to wave soldering is to control the solder temperature, wave height and welding speed, to ensure that the solder joints are full, no virtual welding, while avoiding excessive solder caused by short circuits and other problems.

4.Inspection and debugging

Appearance Inspection: Comprehensive appearance inspection is carried out on the completed welded automotive circuit board PCBA to see whether there are missing components, offset, damage, and whether there are false welding, short-circuiting, leakage of soldering and other problems at the welded joints. With the help of magnifying glasses, microscopes and other tools, inspectors meticulously screen every detail to ensure that the PCBA appearance meets the quality requirements. For example, in the inspection of automotive airbag control PCBA, any defective solder joints may lead to the airbag can not be properly popped at the critical moment, endangering the safety of life, so the appearance of the inspection is critical.

Electrical performance testing: the use of professional test equipment to detect the various electrical parameters of the PCBA, such as on-off test to confirm whether the circuit connection is normal, voltage and current test to verify that the power supply module and the output of the functional circuits in line with the design standards, signal integrity test to ensure that the transmission of high-speed digital signals without error. Car audio PCBA, for example, need to test the frequency response of the audio signal, distortion and other parameters to ensure that the sound quality is clear and pure. Only through the electrical performance test PCBA can enter the next link.

Functional test: simulate the actual operating environment of the car, the PCBA function test. It is installed into the special test tooling and verified in accordance with the operating procedures of automotive electronic equipment in actual use. For example, test the PCBA of automotive electric power steering system, simulate different speeds, steering angle under the working conditions, and observe whether the PCBA can accurately control the power motor to achieve smooth steering. Through the function test, we can find some problems that are hard to detect in the electrical performance test, and ensure that the PCBA meets the actual use requirements of the car.

5.Three-proof processing

Considering the complexity of the automobile driving environment, automotive circuit board PCBA usually need to carry out three-proof (moisture-proof, mould-proof, salt spray-proof) treatment. Using special three-proof paint, through spraying, dipping or brushing, etc., to form a layer of protective film on the surface of PCBA, isolate the external moisture, mould, salt spray and other unfavourable factors, to extend the service life of PCBA. For example, the car driving in the seaside, its electronic equipment faces high salt spray erosion, three anti-protection treatment of PCBA can effectively resist corrosion, to protect the stable operation of the electronic system.

Automotive circuit board PCBA manufacturing details:

Process control system

Automotive circuit board PCBA production using a systematic control process, through the rigorous design of the process route to ensure that the production links in an orderly manner. The system covers parameter configuration, process optimisation and dynamic monitoring mechanism of the whole process, with the help of information technology system to realise real-time traceability of production data and intelligent adjustment, forming a closed-loop quality control network.

Quality Inspection Technology Matrix

Building a multi-dimensional inspection system is a key element of PCBA quality assurance. By integrating core technologies such as AOI three-dimensional optical scanning, X-Ray chromatographic imaging and automated function verification, we have formed a three-dimensional inspection capability that covers the morphology of solder joints, internal structure and electrical performance. Combined with AI algorithms to achieve intelligent identification of defective features, the fault detection accuracy is raised to the micron level.

Component Selection and Supply Chain Control

We have established specifications for the selection of components for automotive electronics, focusing on screening high-reliability devices that comply with the AEC-Q series standards. We implement a supplier hierarchy management system to ensure the stability of devices under severe working conditions such as extreme temperatures and vibration shocks through regular technical audits and full life cycle quality tracking. Establish a localised device database for intelligent BOM management.

Production Environment Protection System

Aiming at the special environmental requirements of automotive electronic products, we configure a multi-level environment control system. The core production area adopts FFU purification unit to build a class 100 dust-free space, and controls the temperature difference of ±1℃ and humidity of 40-60% RH through independent constant temperature and humidity unit, and simultaneously deploys anti-static epoxy floor and ion air curtain device to stabilise the static voltage in the safety zone of 0-±50V, which guarantees the reliability of the products in all aspects.

The manufacturing of automotive circuit board pcba is a highly precise and systematic process, involving multiple key links and strict quality control measures. Through systematic process control, multi-dimensional quality inspection technology, strict device selection and supply chain management, as well as perfect production environment protection system, to ensure that the PCBA in the harsh automotive environment can operate stably and reliably. With the continuous development of automotive electronics technology, the production and manufacturing of PCBA will also continue to move towards higher precision and higher reliability, providing solid technical support for the intelligence and electrification of the automotive industry.