Automotive pcb, is an important component used to mount electronic components and provide connection paths for them in various electronic devices and systems in vehicles. It usually consists of a substrate, conductive paths, circuit components, etc. The substrate materials used in automotive pcb boards are mainly high temperature, heat,humidity and corrosion resistant to cope with the various challenges of the automotive environment. The substrate is usually printed with conductive paths,these copper conductive paths are known as printed circuits, which connect circuit components and form a path for current. Circuit components, such as resistors,capacitors,inductors,diodes,transistors, etc.,are key components of an automobile’s circuit board, whether it is controlling the car’s powertrain or functions such as environmental sensing and navigation.

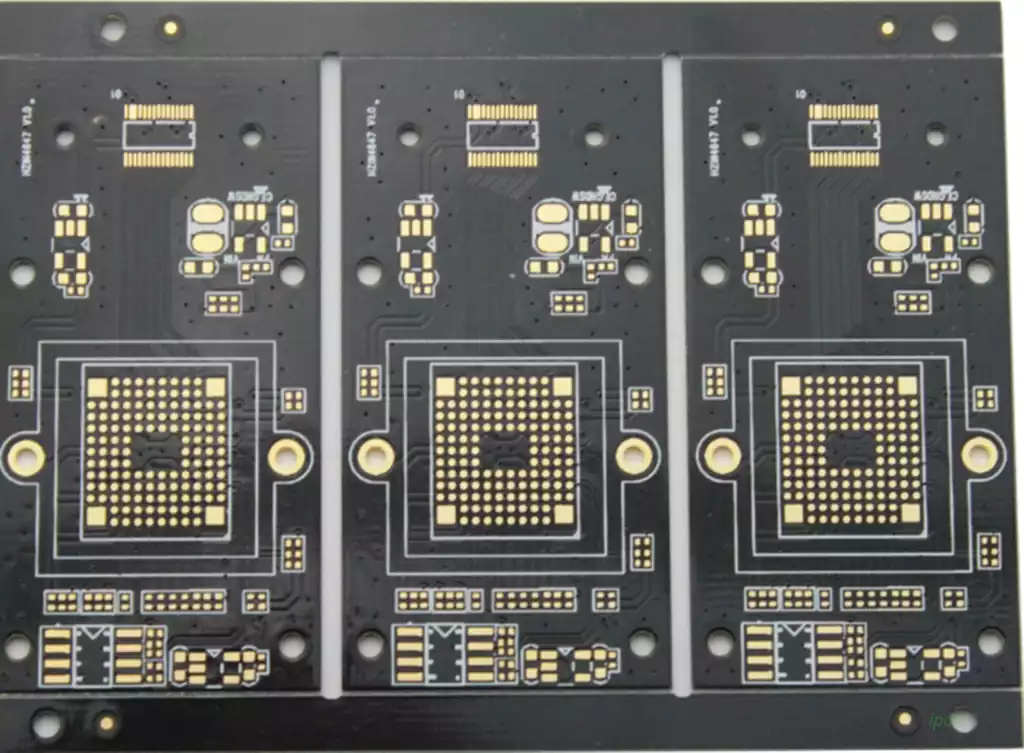

Circuit boards for automobiles are installed in various parts of the body, including computers, ceramic circuit boards, alumina ceramic circuit boards, aluminum nitride ceramic circuit boards,circuit boards,PCB boards,aluminum substrates,high-frequency boards, thick copper boards, impedance boards, PCBs, super-thin circuit boards,ultra-thin circuit boards,printed (copper etching technology) circuit boards, and so on.Circuit boards miniaturize and visualize circuits and play an important role in mass production of fixed circuits and optimizing the layout of electrical appliances.Printed circuit boards are categorized into single panel,double panel and multilayer circuit boards.Single-sided boards are based on PCBs,where parts are concentrated on one side and wires on the other.Dual sided boards are an extension of single sided boards and are used when a single layer of wiring does not meet the needs of an electronic product. Multilayer circuit boards are the product of the development of electronic information technology to high-speed,multi-functional,high-capacity,small volume, thin, lightweight direction. Circuit boards can also be divided into soft boards (FPC),hard boards (PCB) and soft and hard combination boards (FPCB) according to the characteristics.

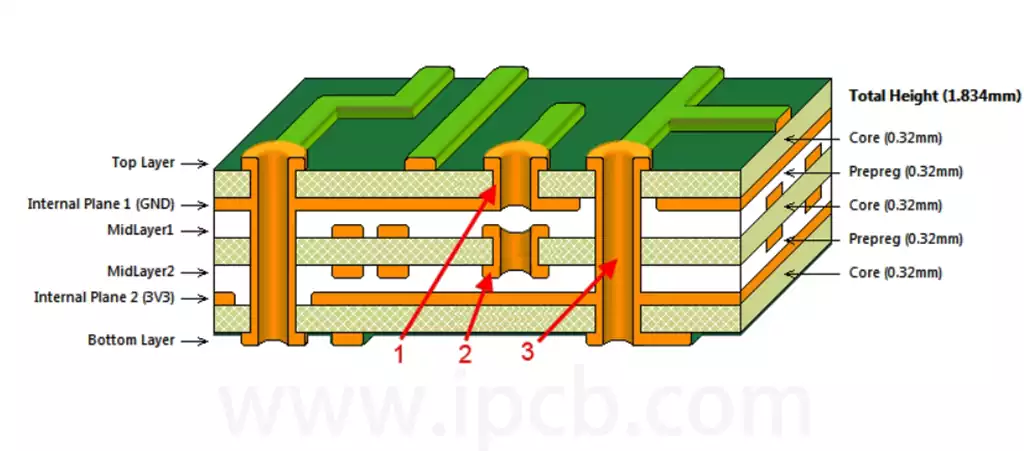

A multilayer board structure is usually used,which includes an inner layer of copper foil,a dielectric layer and an outer layer of copper foil. According to different functions and requirements, automotive circuit boards can be categorized into three types:rigid circuit boards and flexible circuit boards, and rigid-flexible combination boards, in which rigid circuit boards are suitable for occasions requiring high mechanical strength and stability, while flexible circuit boards are suitable for occasions requiring bending or flexing.

Automotive circuit boards play a vital role in automobiles.It is the bridge between various electronic devices inside the car,responsible for the transmission of information and the implementation of instructions.Without the circuit board,the electronic equipment inside the car will not work properly,and the performance and safety of the car will be seriously affected.

It also carries the heavy responsibility of automotive intelligence and electrification.With the continuous development of automobile technology, the electronic equipment inside the car is more and more complicated.The normal operation of these devices and the realization of the function are inseparable from the support of the circuit board.Therefore, the performance and quality of the circuit board will directly affect the level of automotive intelligence and electrification.

It also affects the energy-saving and environmental performance of the car.With the continuous improvement of environmental awareness,automotive energy saving and environmental protection has become an important indicator.As the core component of automotive electronic system,the performance and quality of the circuit board will directly affect the energy consumption and emissions of the car.High-quality circuit boards can reduce the energy consumption and emissions of automobiles and improve the environmental performance of automobiles.

Automotive circuit board with anti-vibration,high-temperature,corrosion-resistant features to adapt to the harsh environment in which the car is located; its materials and manufacturing process requirements are higher to ensure the stability and reliability of the circuit board.Its biggest function, undoubtedly, is to provide a variety of electronic equipment and systems for the car,providing connections to electronic components,and the formation of current pathways. Its performance parameters mainly include high temperature resistance,vibration resistance,humidity resistance,corrosion resistance and other properties. Precisely because of the complexity of the working environment of the car,this printed wiring board needs to cope with a variety of harsh environments such as high temperature, humidity,vibration and shock,so in the selection of materials and design,there are high requirements for weather resistance and strength, etc., which are more powerful than the general circuit board.

The complexity of modern automobiles far exceeds the once visible to the naked eye of the driver’s mechanical equipment,automotive pcb is used in many areas.Such as power control system,used to control the car’s entire power system,including the engine,transmission,brakes,etc.;vehicle information system, used to achieve navigation,communication,entertainment and other functions; safety control system,here involved,including body stabilization system,airbag control, etc.; environmental awareness systems,such as reversing radar, raindrop detection and so on.Each function requires targeted design and production of automotive pcb boards, the performance of the automotive circuit board has strict requirements.