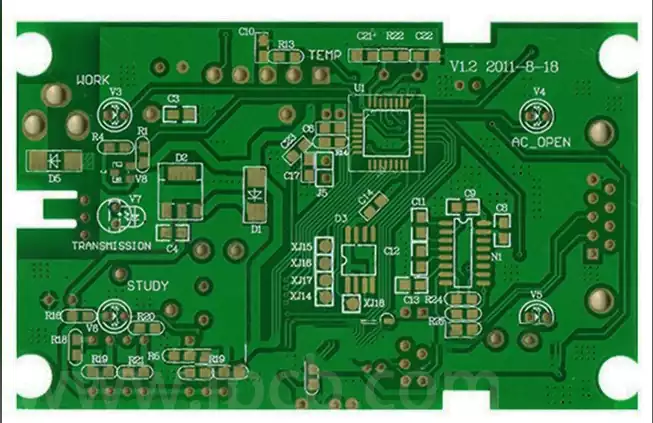

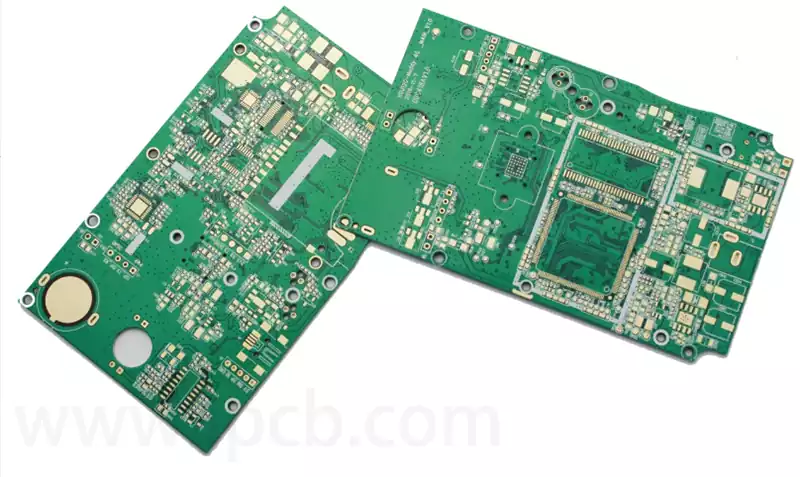

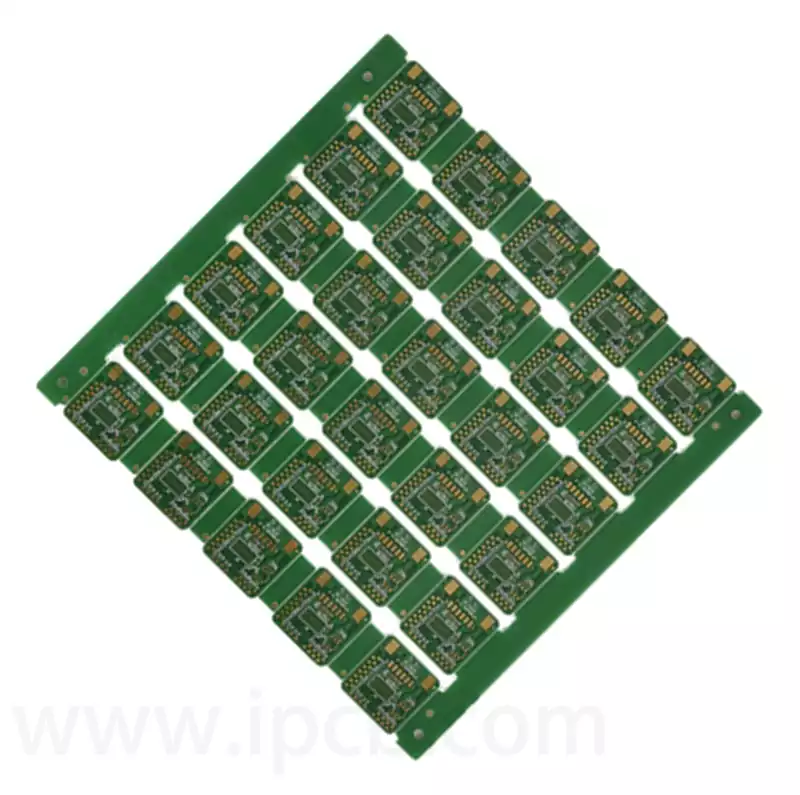

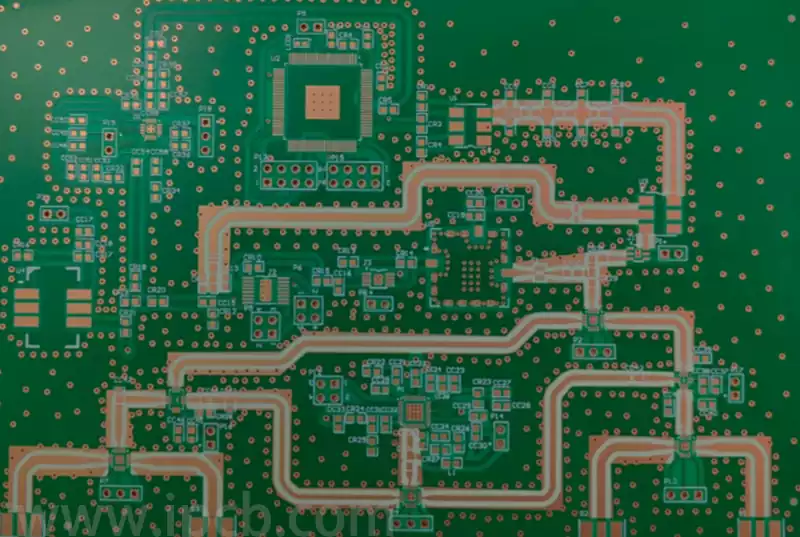

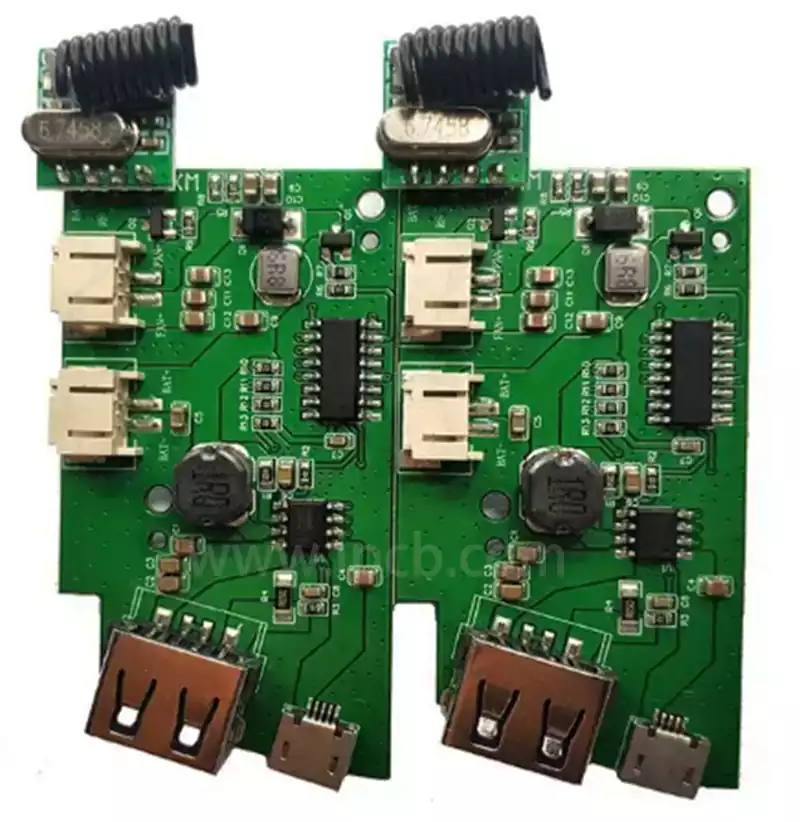

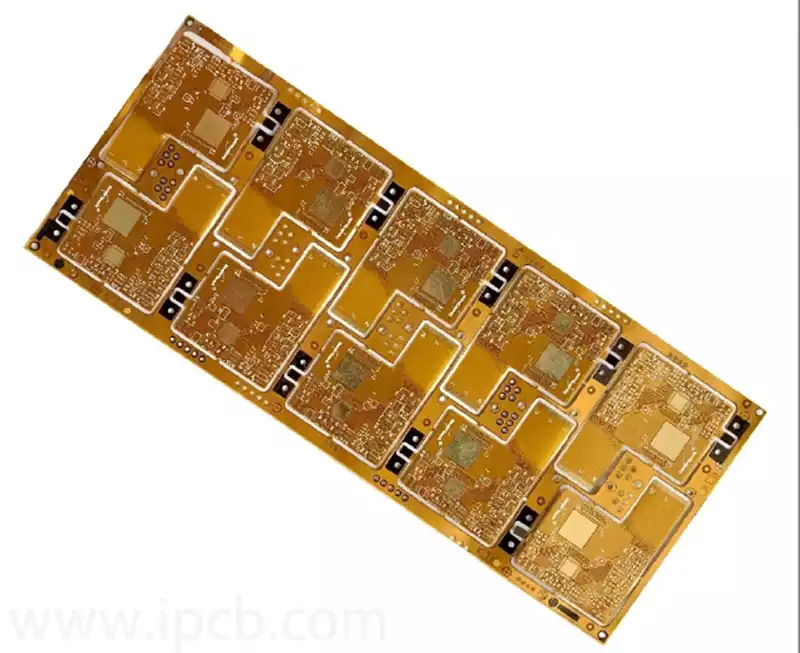

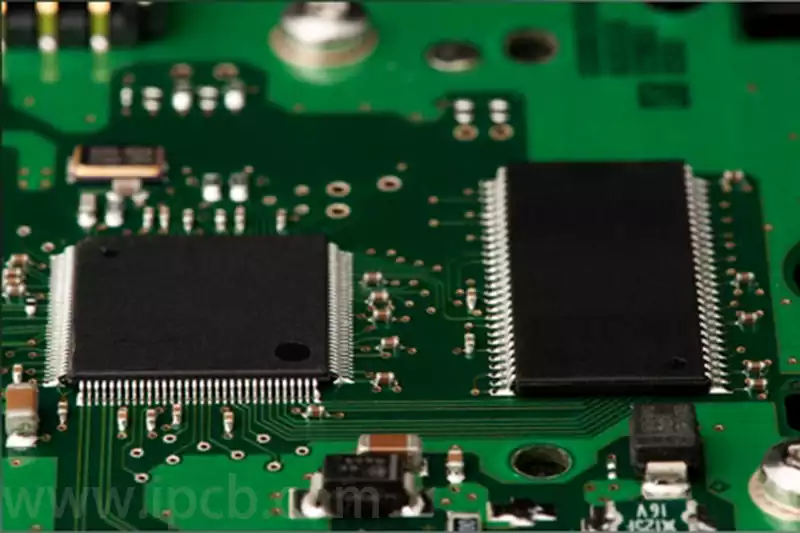

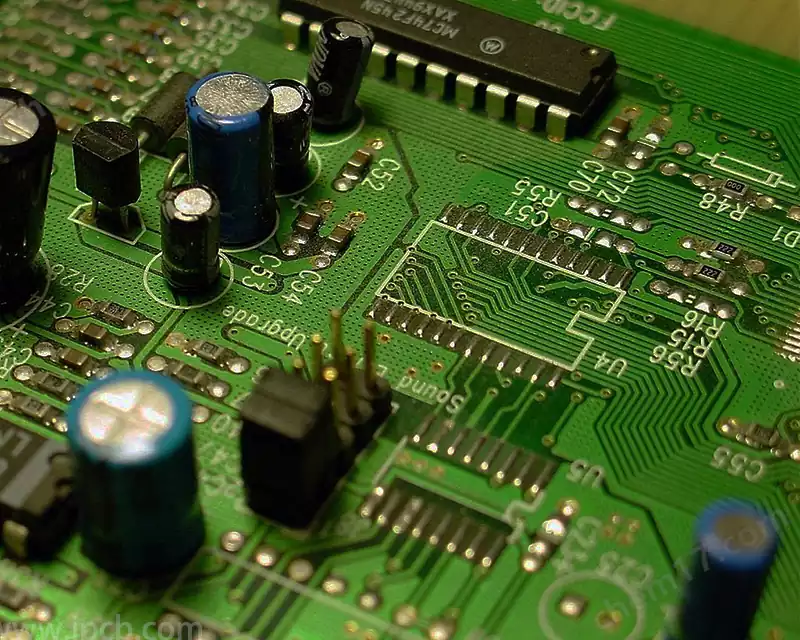

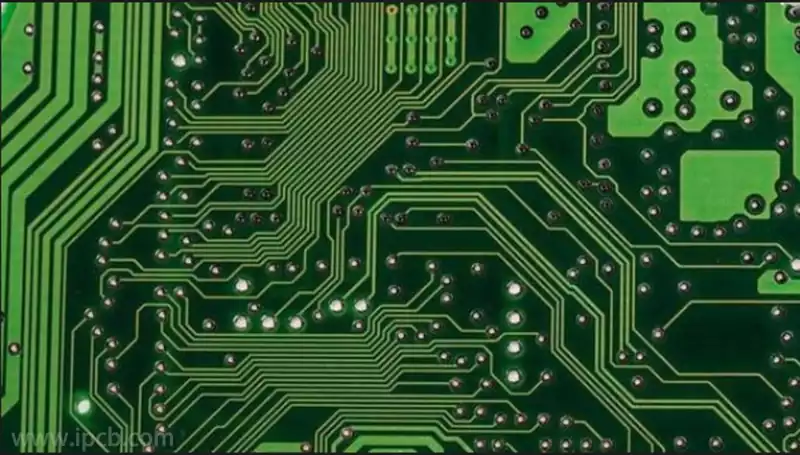

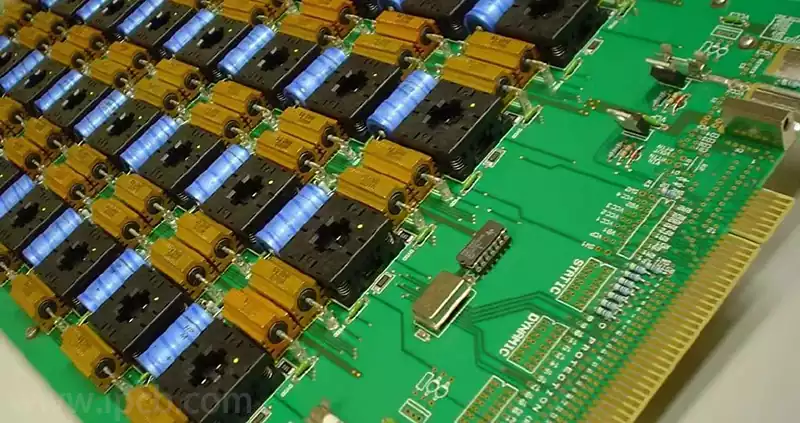

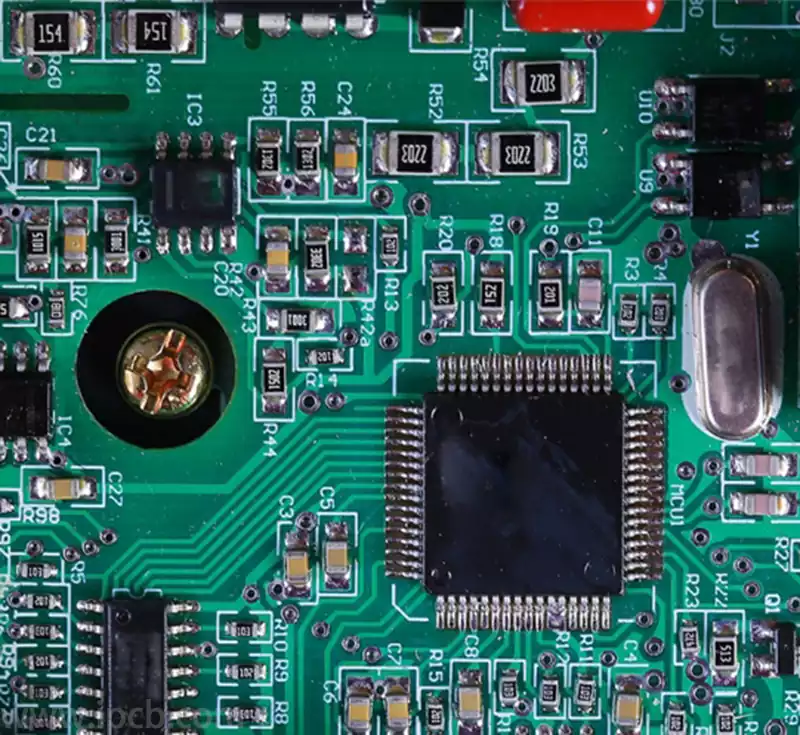

Double sided PCB board assembly process

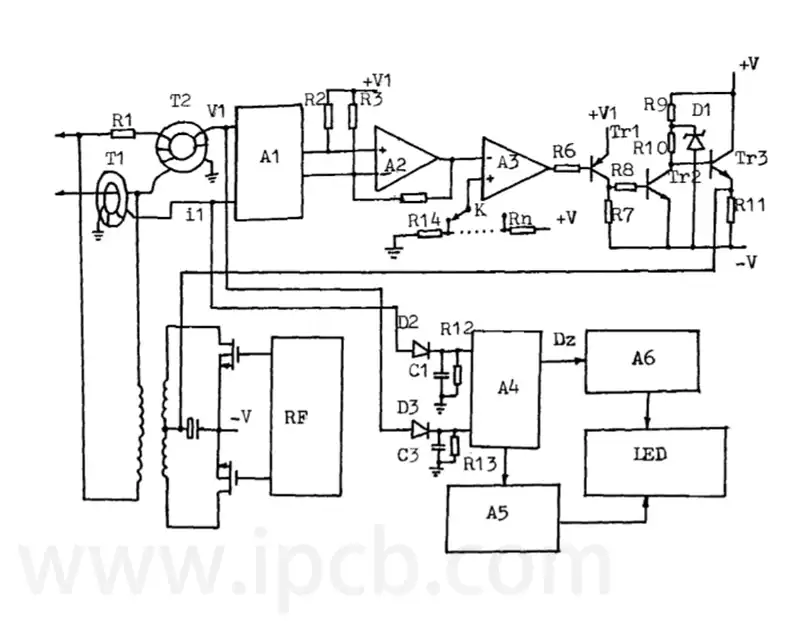

In the field of electronic manufacturing, double-sided PCB board assembly by virtue of its high integration, small size and other advantages, widely used in various types of electronic products, from smart phones, tablet computers to industrial control equipment, automotive electronic systems, are inseparable from its figure. It can not only effectively save board space, but […]