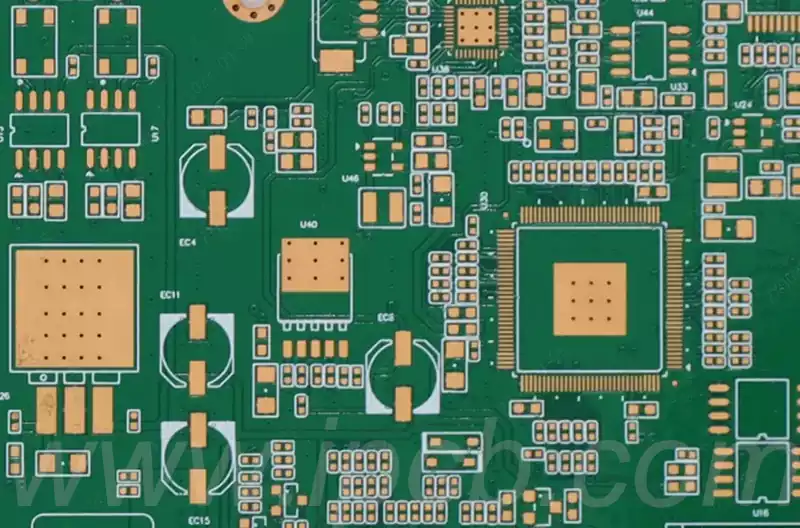

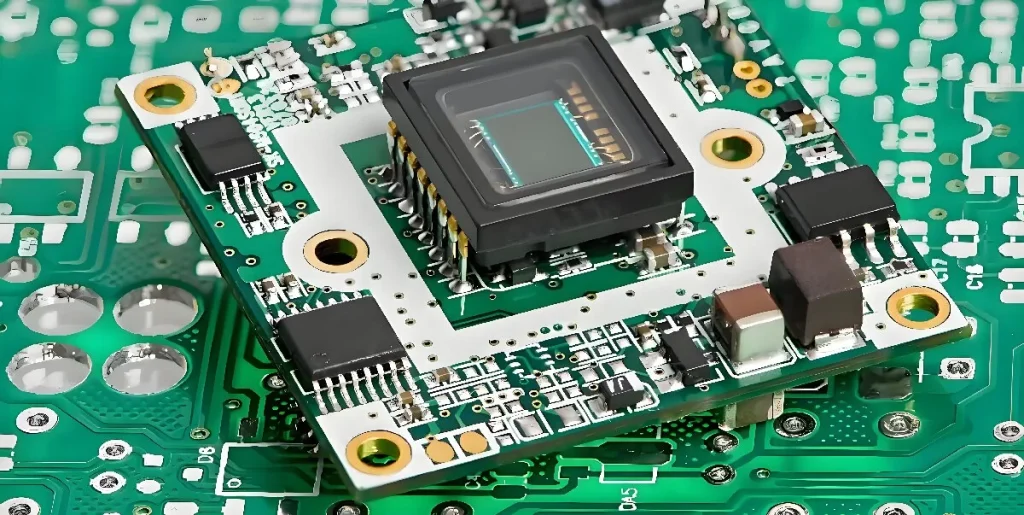

Why double sided ceramic pcb boards

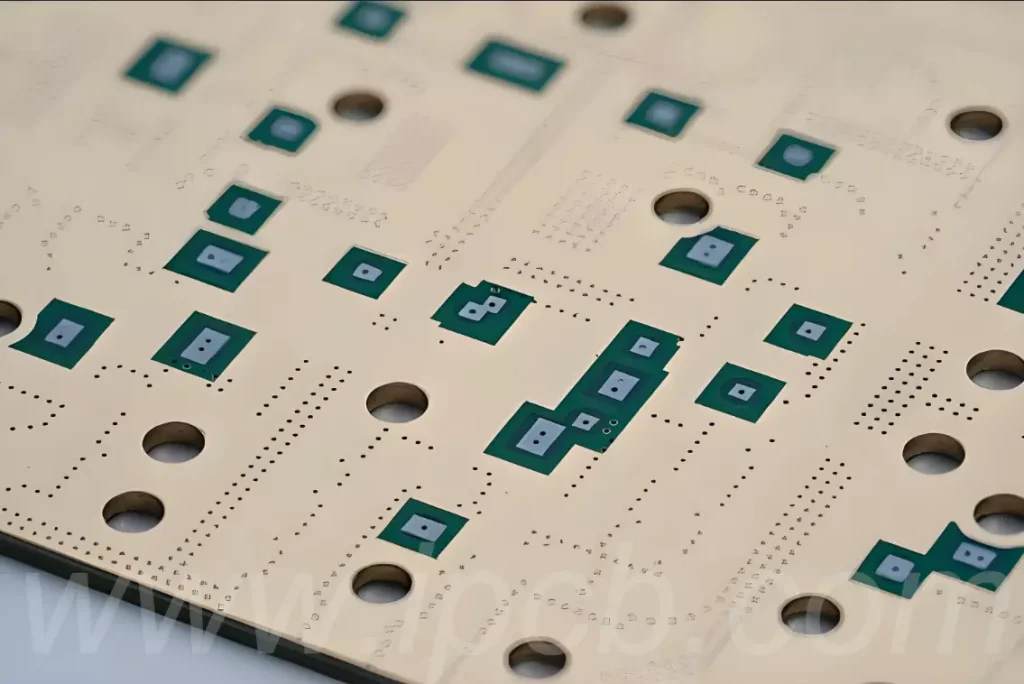

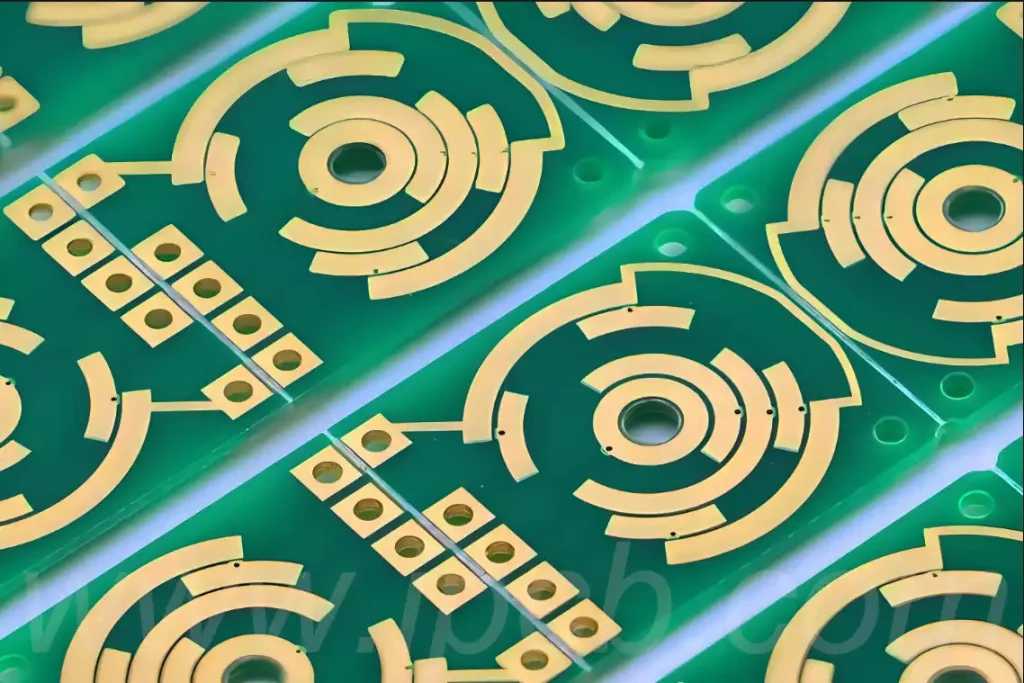

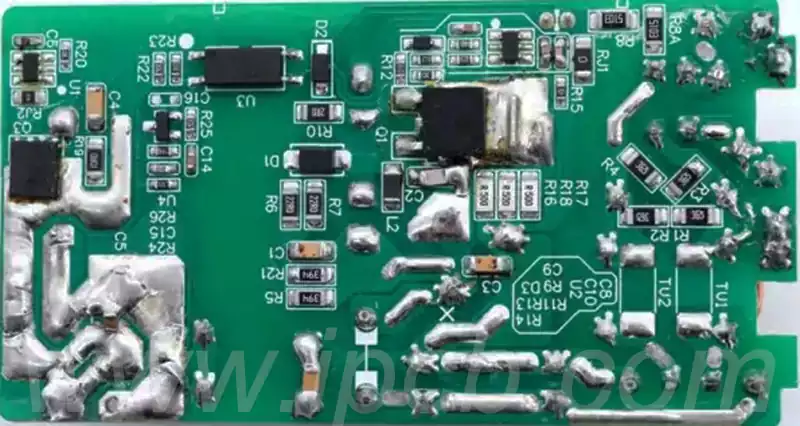

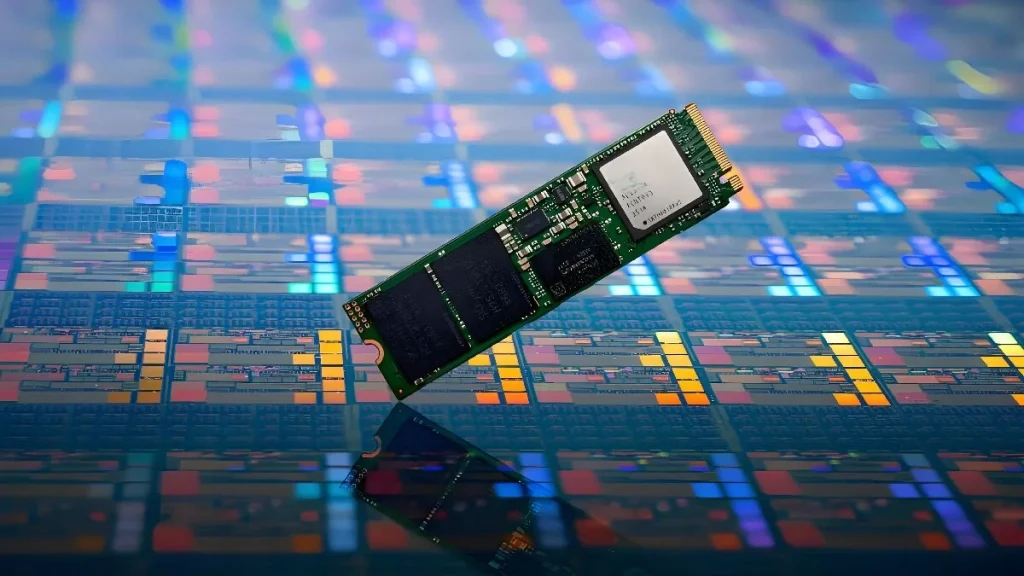

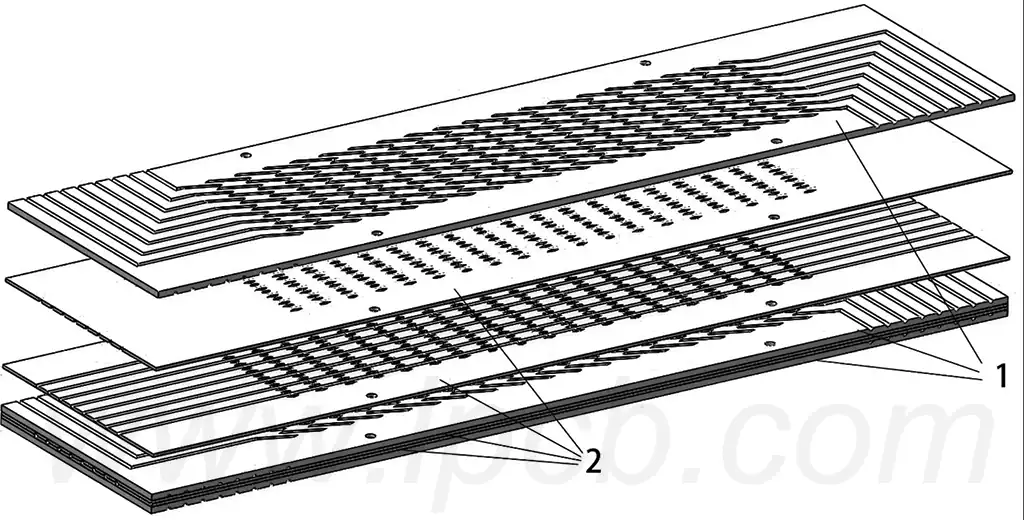

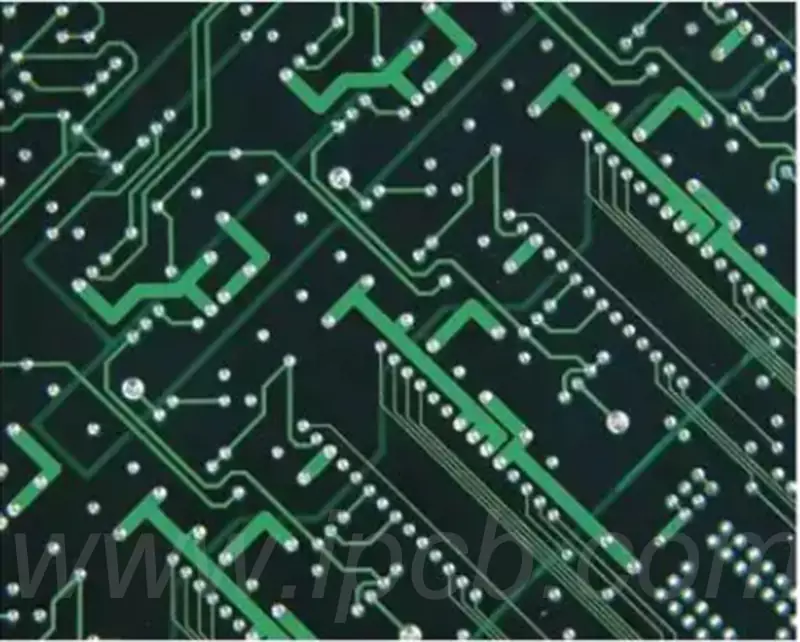

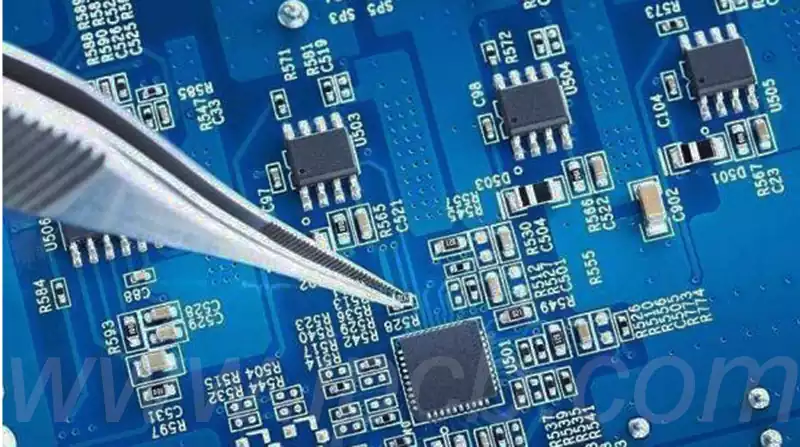

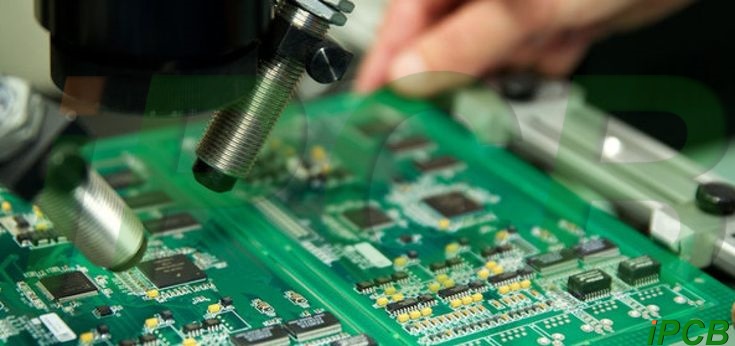

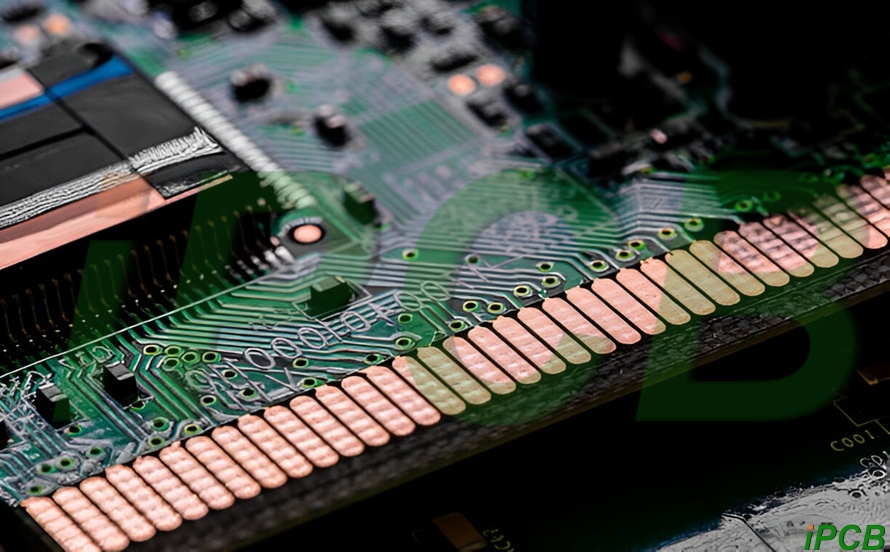

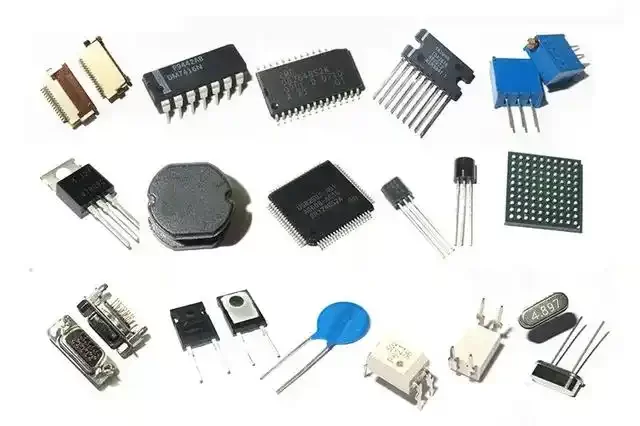

Double sided ceramic pcb board, also known as double sided ceramic circuit board, is commonly found in many electronic products that are used on a daily basis. While single-sided ceramic circuit boards have a conductive surface, double sided ceramic pcb boards have a conductive layer on each side. Compared to single-sided ceramic circuit boards, an […]