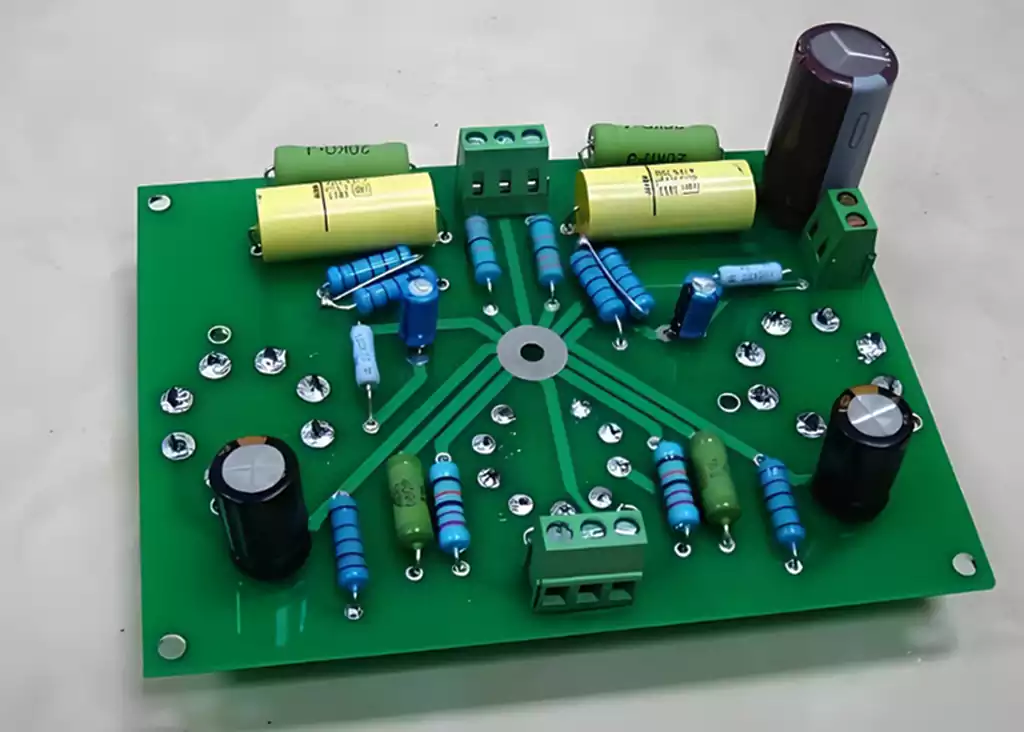

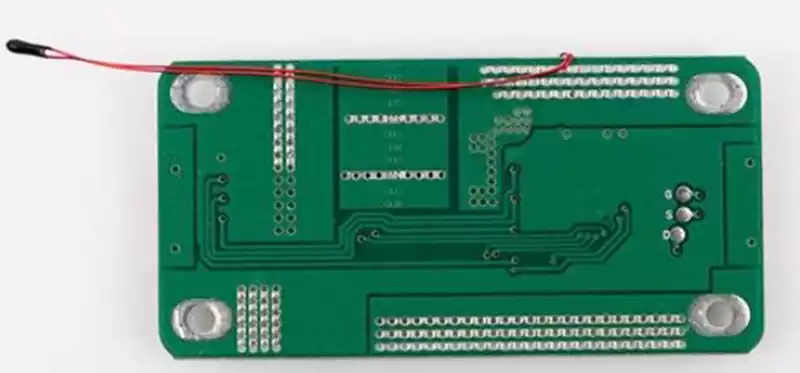

Application of x-ray machine for pcb

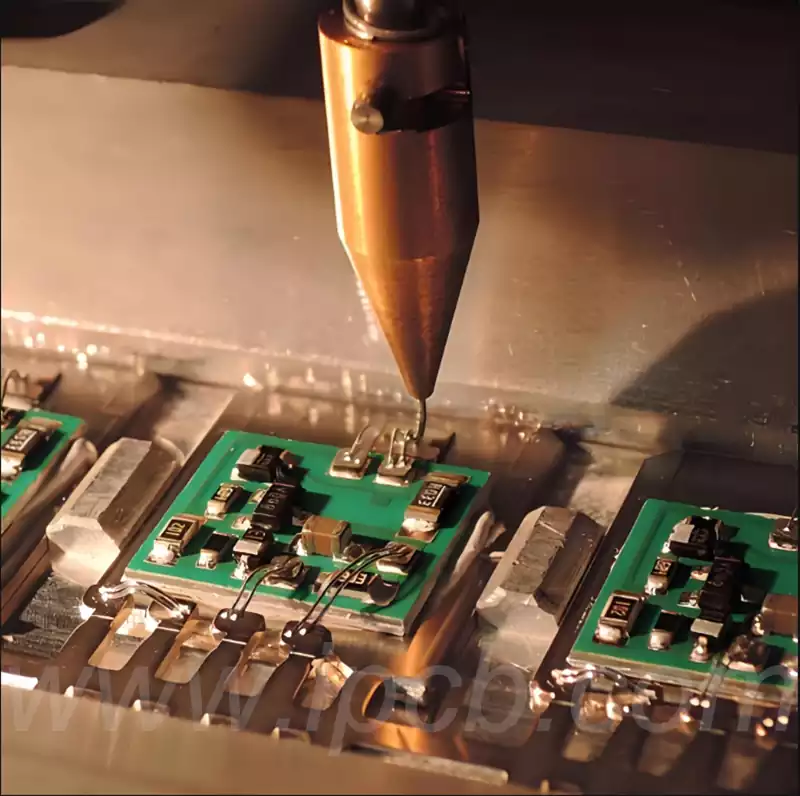

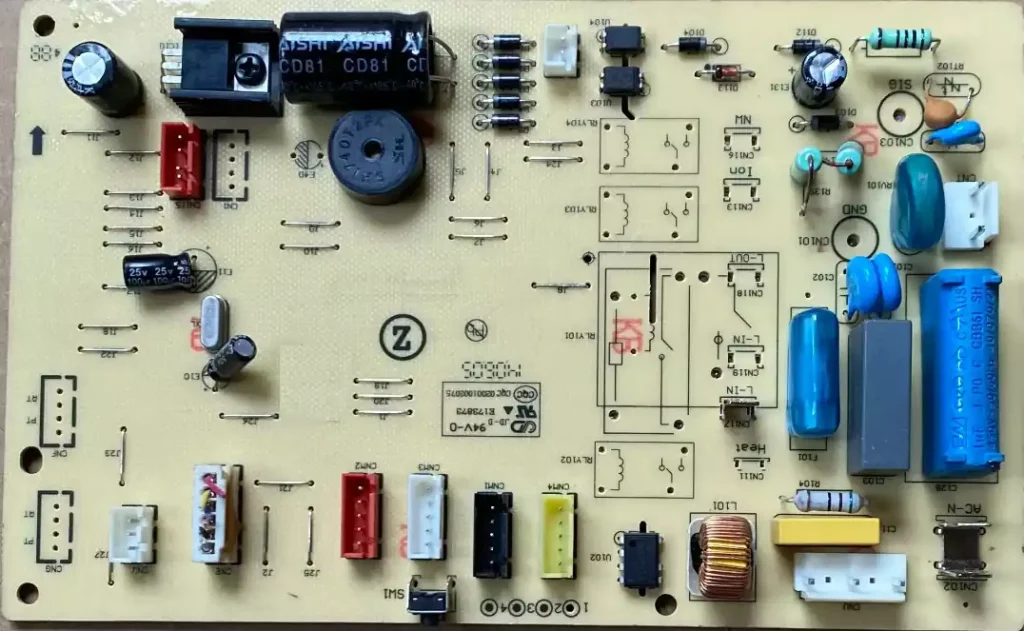

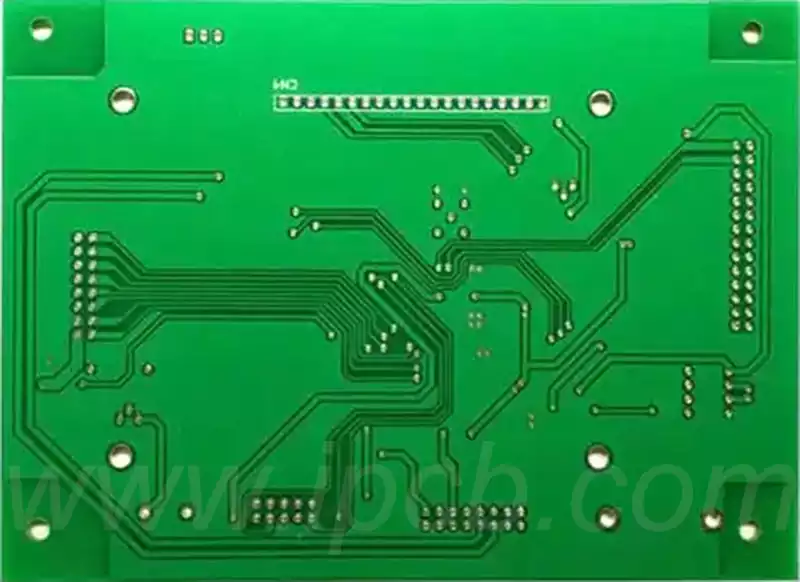

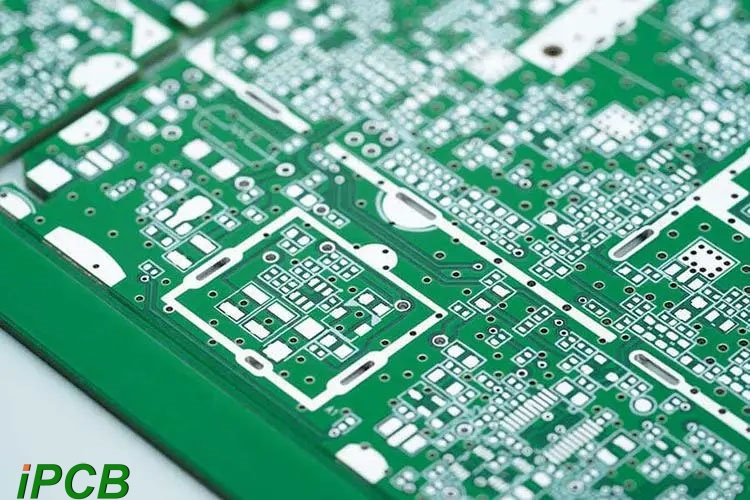

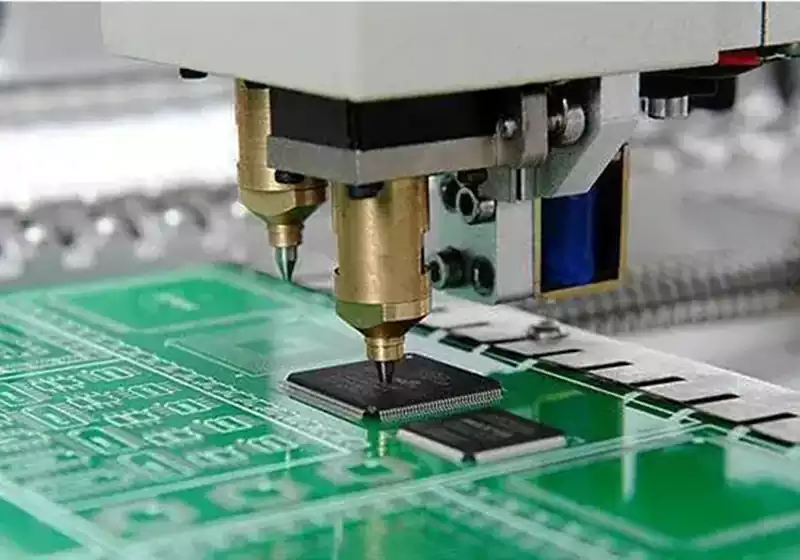

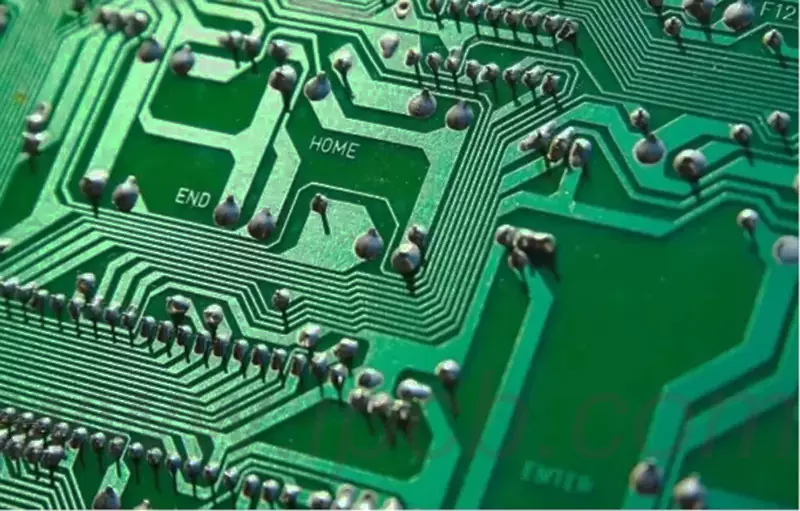

The x-ray machine for pcb is a non-destructive inspection device for printed circuit boards using the X-ray transmission principle. With the help of X-ray imaging, it is able to accurately visualise the internal structure of the PCB as well as the subtleties of the solder joints, such as holes in the solder joints, defective soldering, […]