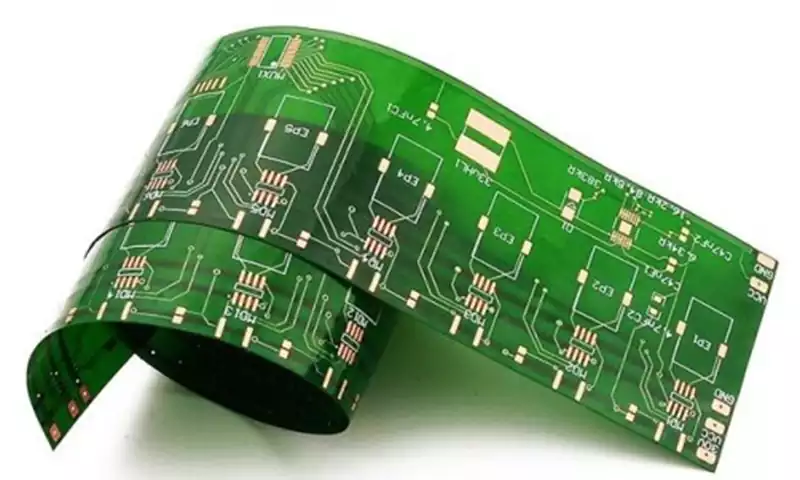

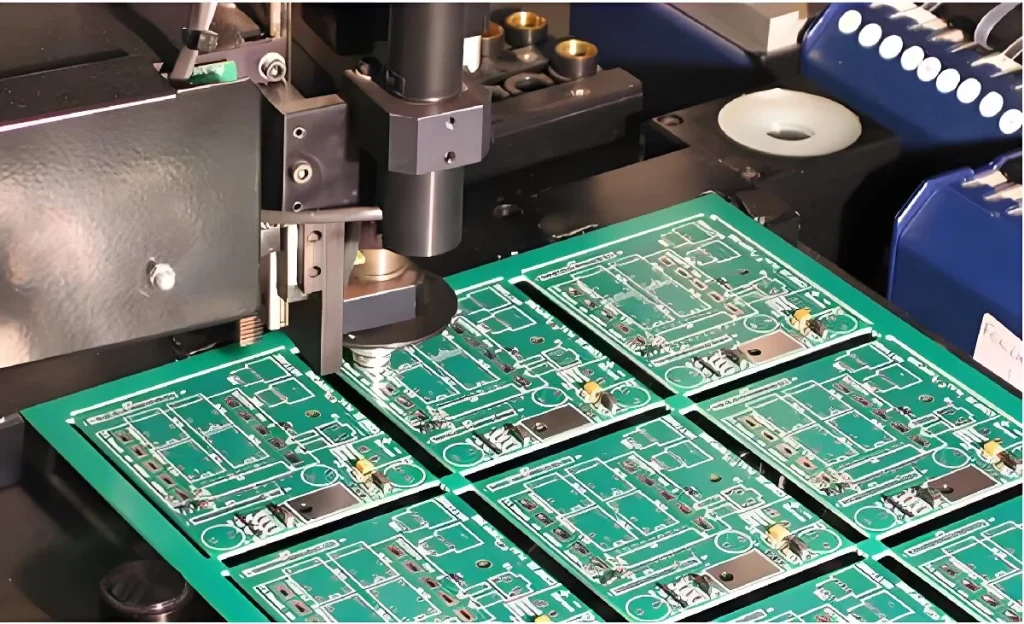

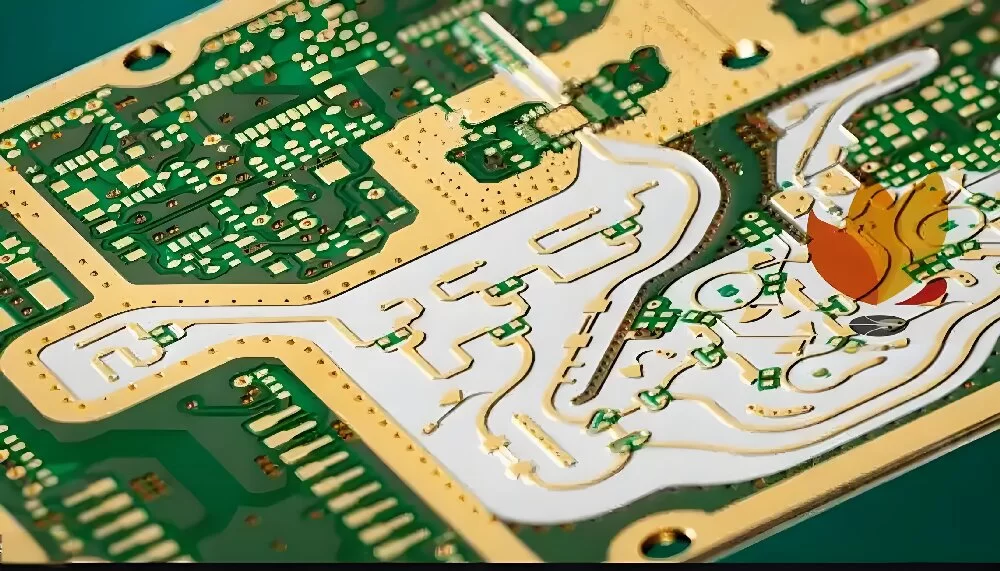

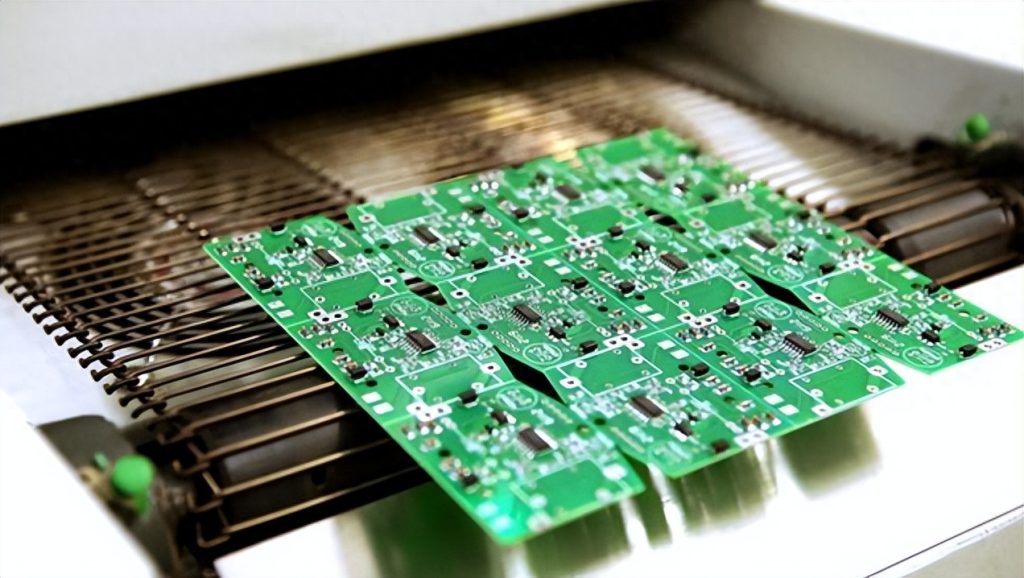

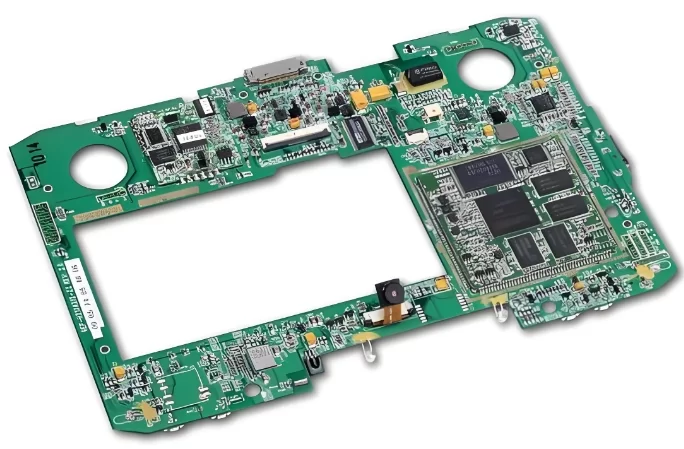

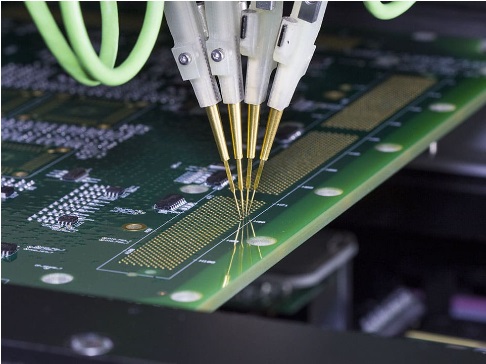

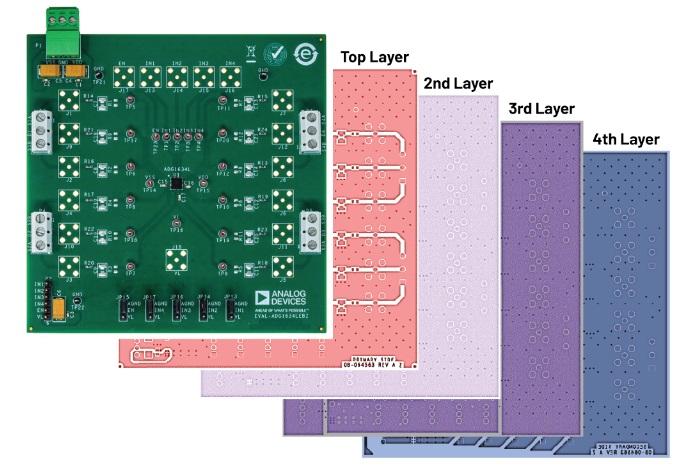

flex pcb production

Flex pcb production starts with designing the circuit board structure and layout. A flexible circuit board is a printed circuit board that is designed to be flexible and bendable. Unlike traditional rigid circuit boards, flexible circuit boards are made of thin, flexible materials such as polyimide or polyester film. These materials allow the circuit board […]