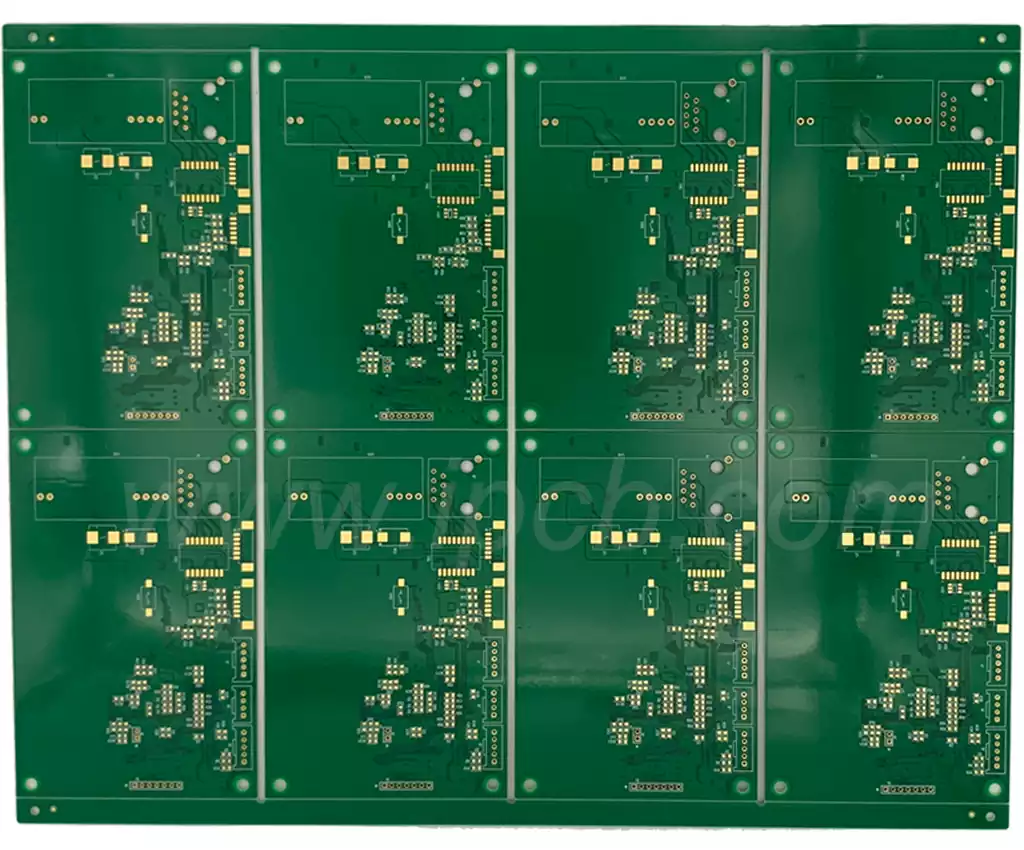

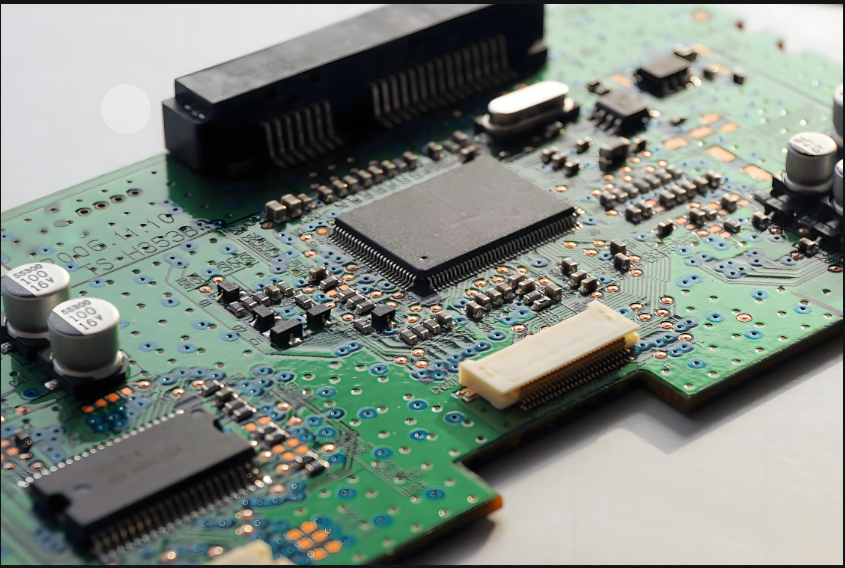

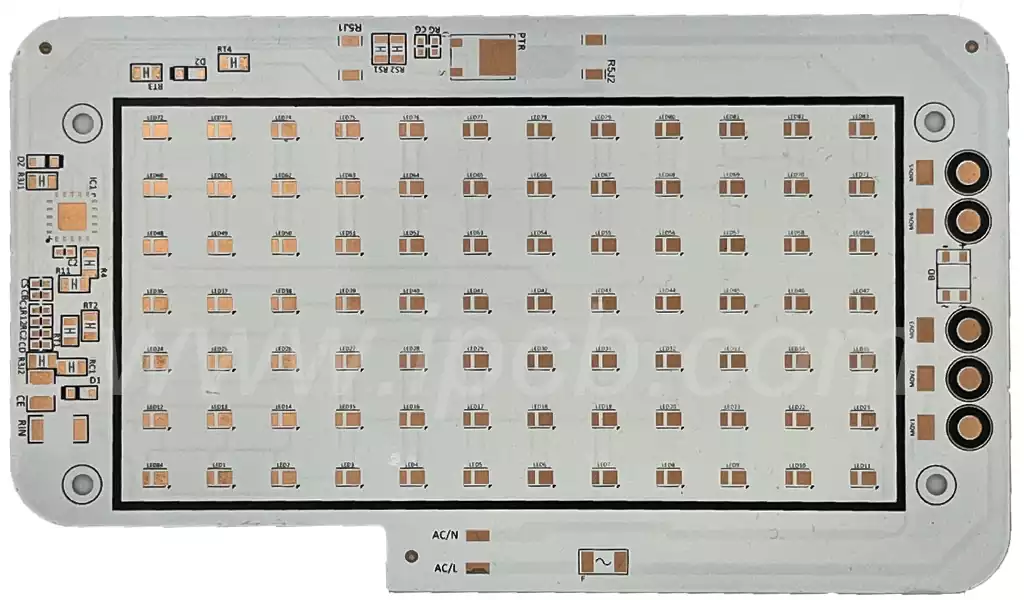

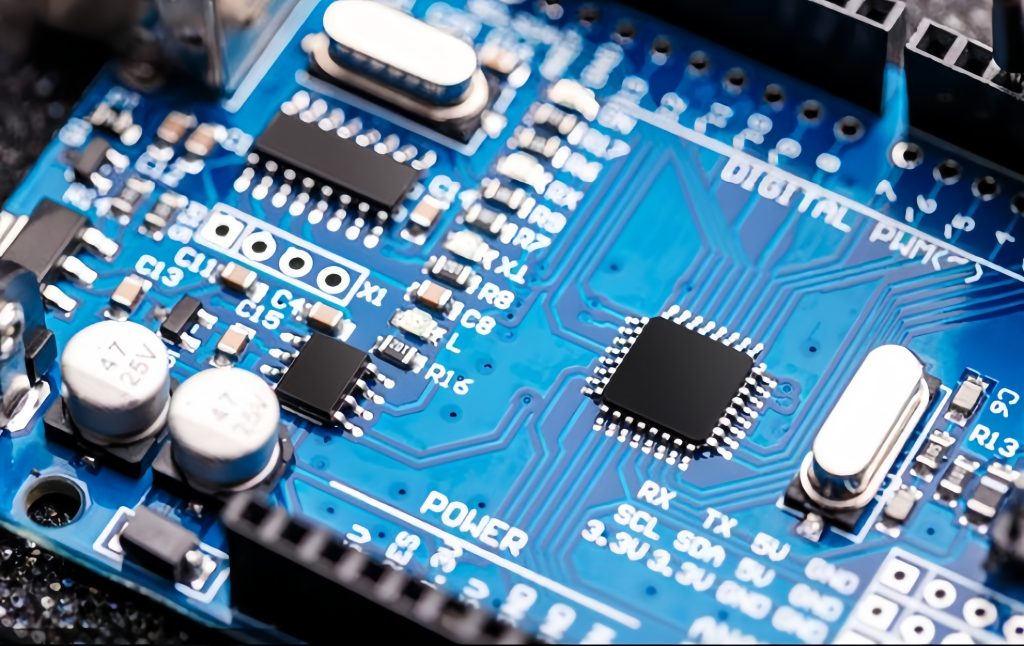

Enhancing PCB Performance with Advanced PCB Adhesive Solutions

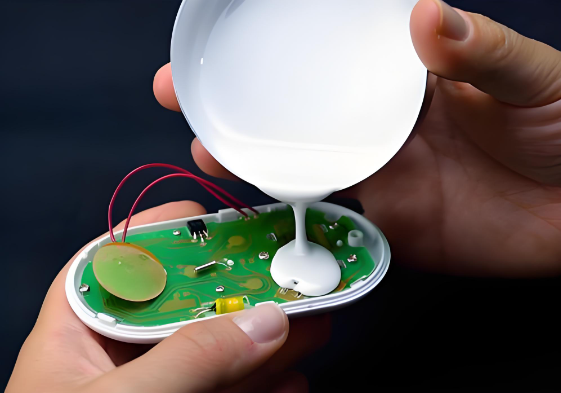

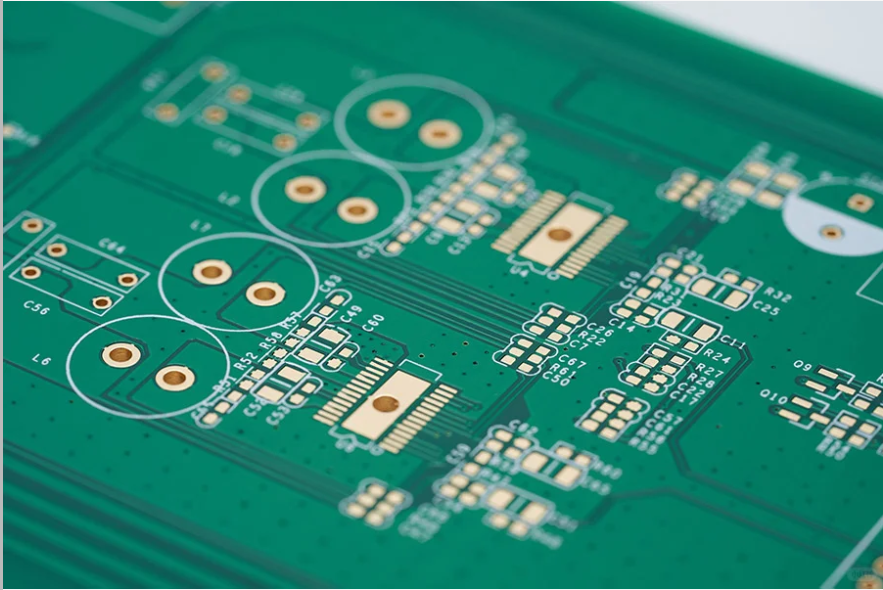

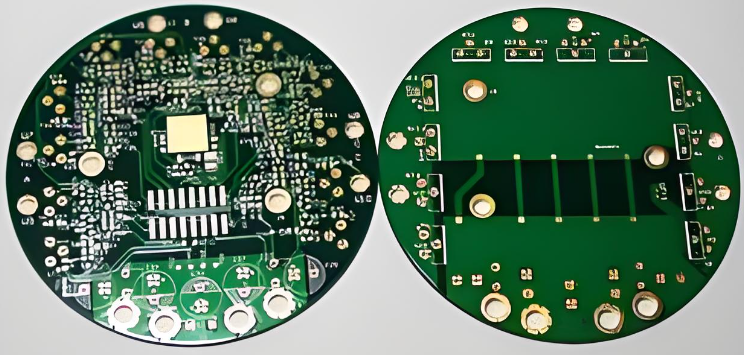

Adhesives play a critical role in the manufacturing and assembly of printed circuit boards (PCBs). Their primary functions include bonding components to the board, providing electrical insulation, and ensuring mechanical stability. With the ongoing miniaturization and complexity of electronic devices, the demand for high-performance adhesives has significantly increased. This article explores various types of adhesives […]