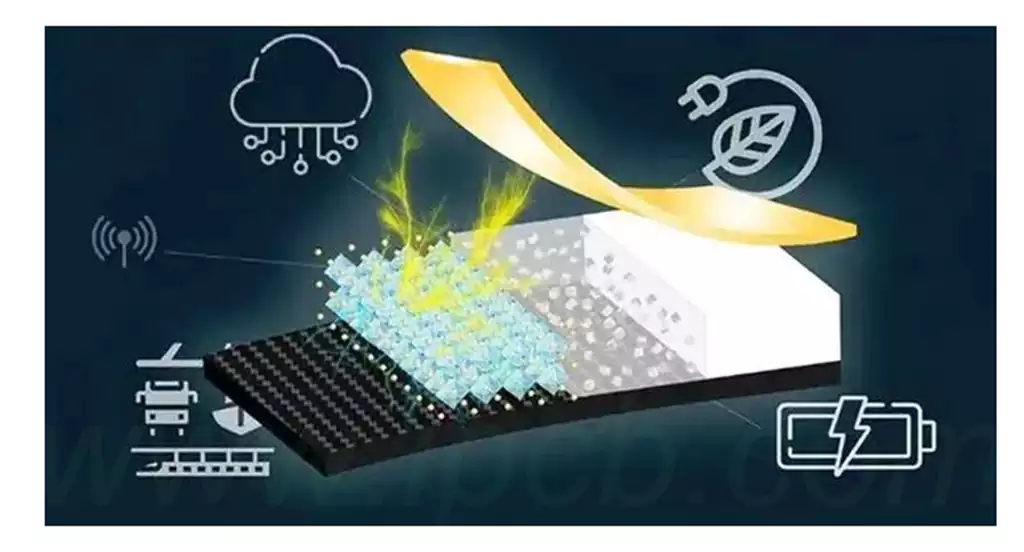

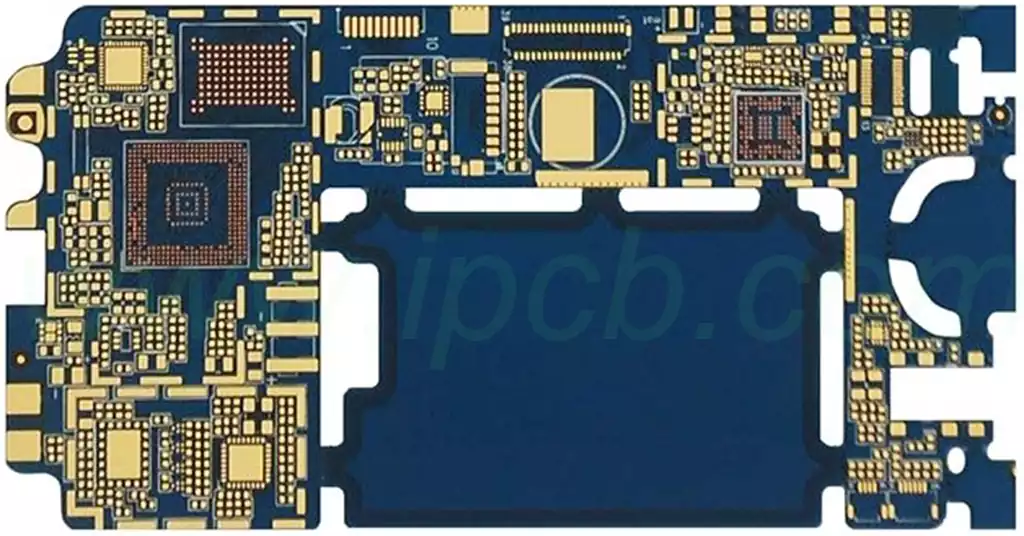

Energy Harvesting PCB Technology

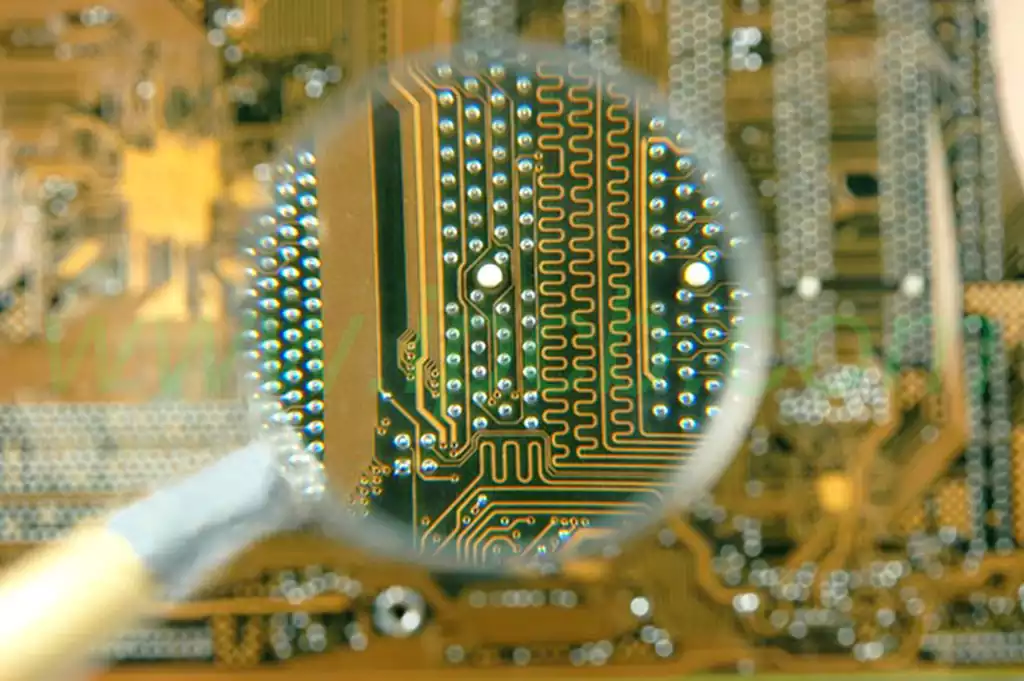

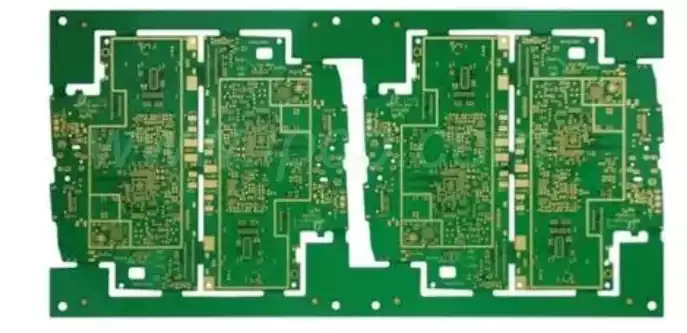

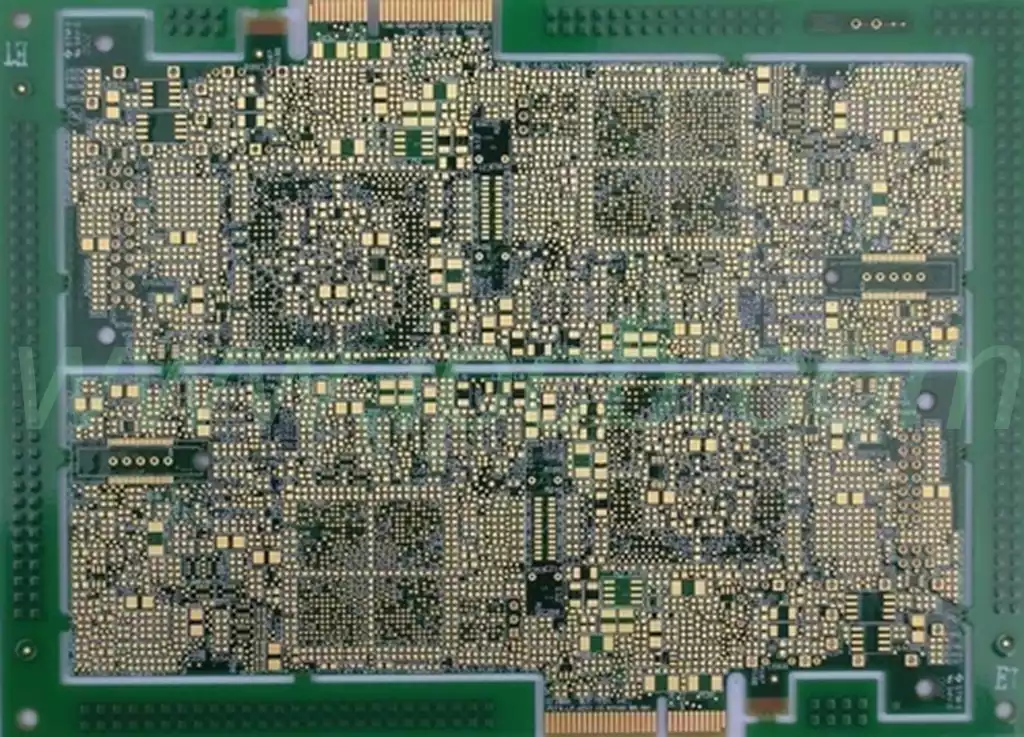

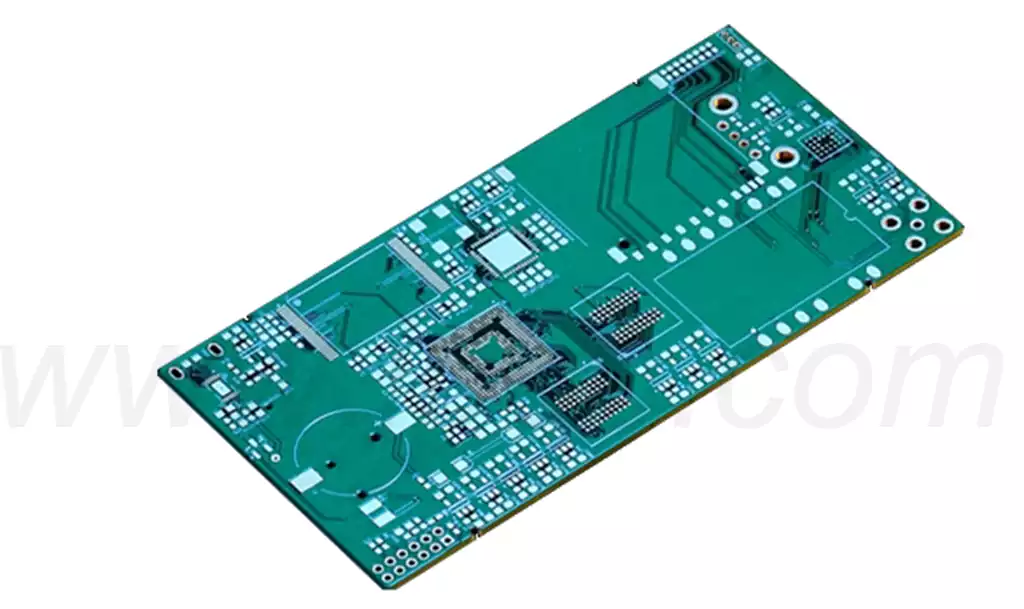

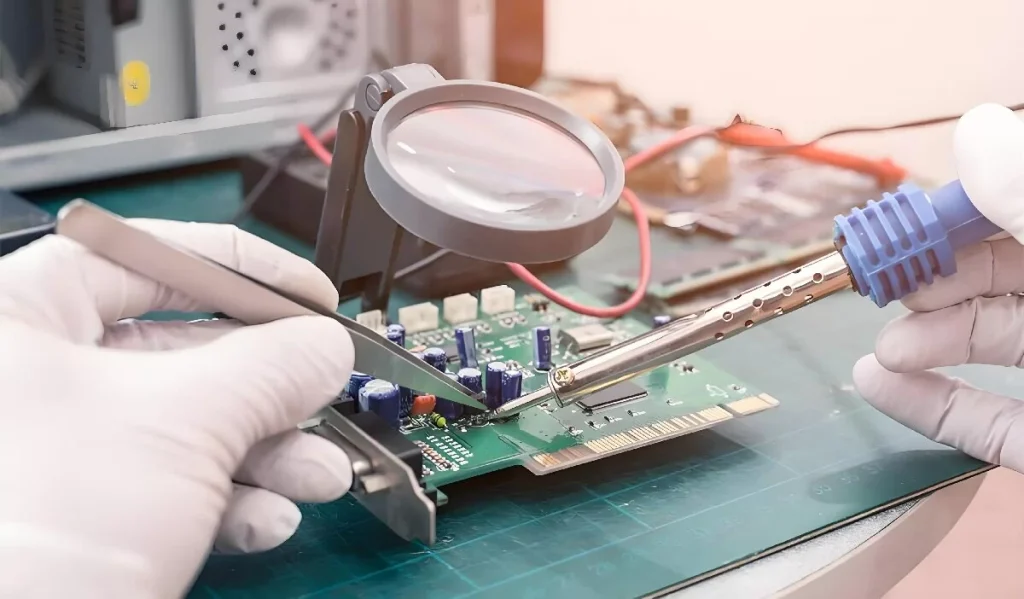

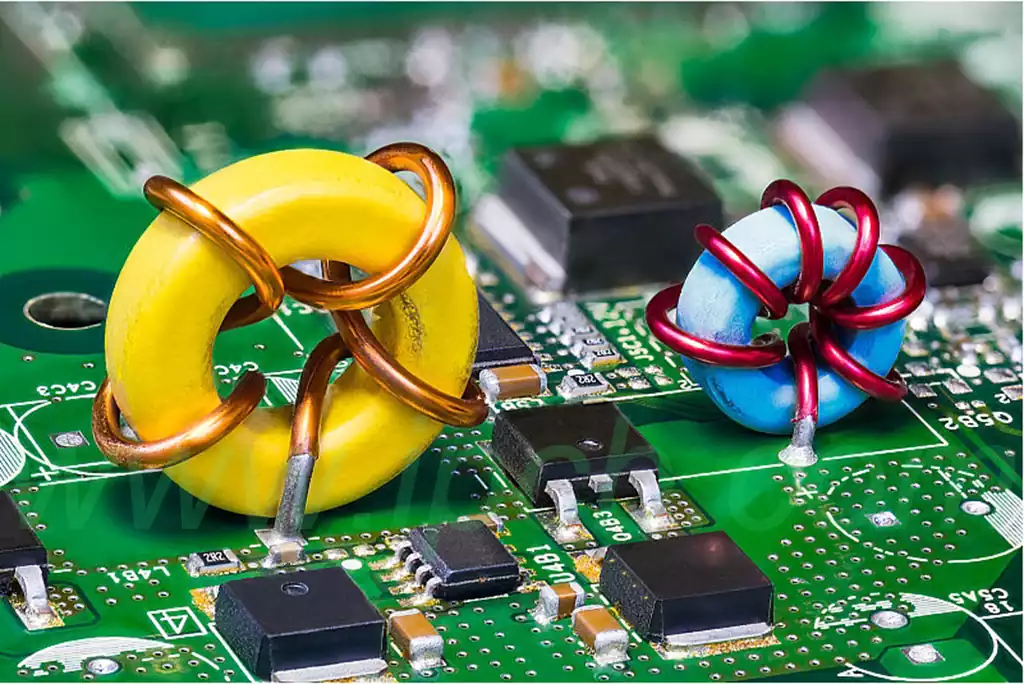

An energy harvesting PCB is a solution that integrates multiple energy harvesting technologies onto a circuit board to harvest and convert energy from the surrounding environment into electricity. It typically involves the use of technologies such as solar cells, thermoelectric generators, piezoelectric materials, or radio frequency (RF) collectors to self-power a device or improve battery […]