Prepreg pcb, also known as prepreg, is a key material used in the production of multilayer printed circuit boards (PCBs). Prepreg consists mainly of a resin and a reinforcing material (e.g. fiberglass cloth), which is partially pre-impregnated with a resin that has a certain degree of fluidity after a special process. This structure enables prepreg circuit boards to achieve stronger adhesion and curability during subsequent processing, providing a high-quality base material for circuit board preparation.

Characteristics of prepreg pcb

1.Excellent dielectric properties

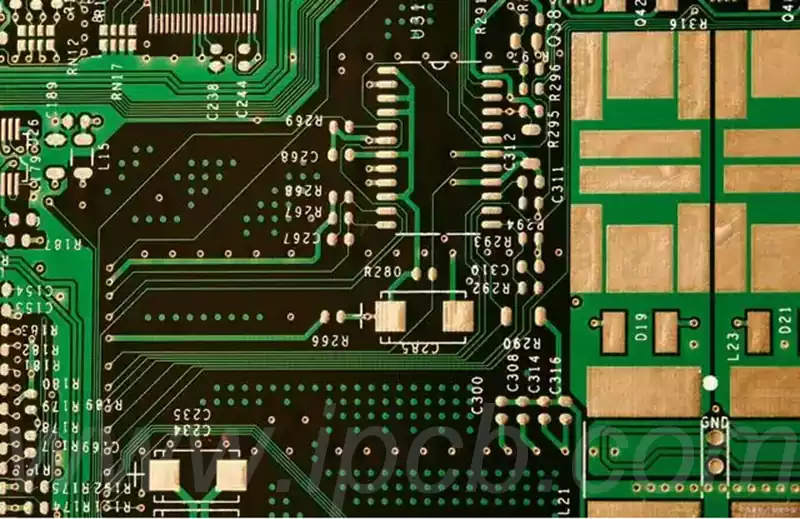

A distinctive feature of prepreg pcb is their excellent dielectric properties,which make them outstanding in high-frequency and high-speed circuit applications. Properly selected resins and reinforcement materials can effectively reduce signal attenuation and enhance the clarity and stability of signal transmission.This is particularly important in RF (radio frequency) and microwave circuit design.

2.High Strength and Structural Stability

Prepreg pcb is usually composed of reinforcing materials (such as fiberglass cloth) and epoxy resins, which give them high mechanical strength and good structural stability.Compared with conventional materials, prepreg circuit boards can withstand greater pressure and temperature changes when stacked in multiple layers, thus ensuring the reliability of PCBs in complex environments.This high strength is the basis for manufacturing high-performance devices.

3.Good moisture resistance

Pre-impregnated circuit boards effectively resist moisture through its material properties to prevent moisture damage that occurs during storage and transportation. This characteristic is essential to ensure stable PCB performance in harsh environments,especially in humid or shifting weather conditions.

4.Compatibility and Customizability

The materials and formulations of prepreg circuit boards can be customized for different applications to suit specific performance requirements and operating environments.This compatibility allows prepreg boards to be used in a wide range of applications such as consumer electronics,communication devices and automotive electronics. Manufacturers can optimize the overall performance of the board by selecting the right material formulation for specific design requirements.

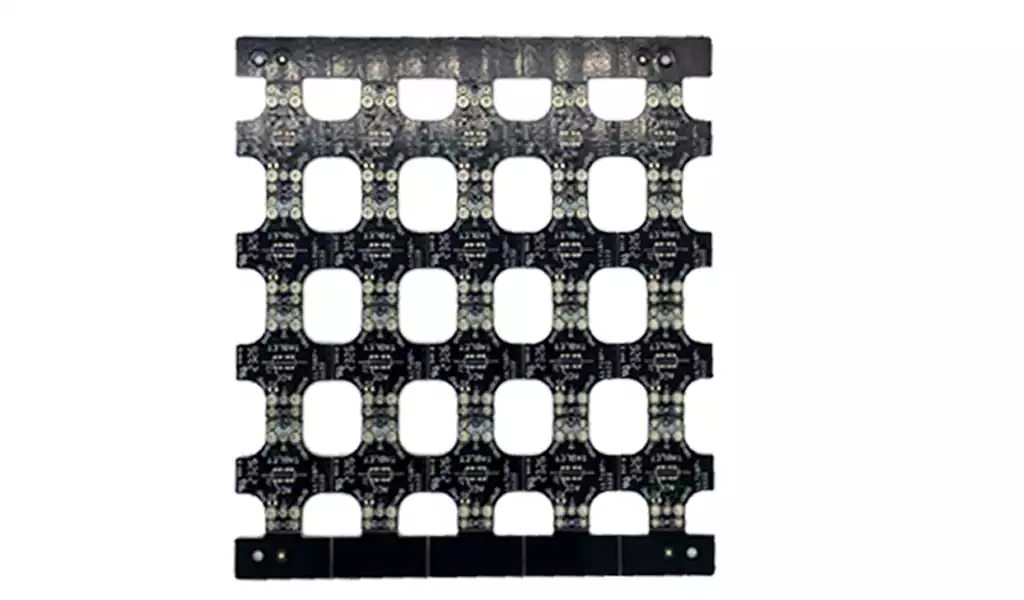

5.Suitable for multilayer boards

Prepreg pcb is particularly suitable for multilayer circuit board manufacturing. In multilayer PCBs, the fluidity of the prepreg ensures a uniform bond between each layer, avoiding interlayer bubbles or stress concentrations. This feature makes multilayer PCBs more reliable and stable in complex designs.

Manufacturing processes for prepreg circuit boards are constantly being innovated to improve product quality,performance and productivity. In recent years, improvements in materials, the use of automation technology, and the introduction of new production processes have all been important innovations to watch. These advances not only promote the simplification and efficiency of the PCB manufacturing process, but also provide solutions to meet the growing market demand.

- Material Innovation

Material innovations in prepreg pcb is mainly reflected in the improvement of resins and reinforcement materials. For example, the development of higher performance epoxy resins and composite materials to enhance the heat resistance, mechanical strength and electrical properties of the circuit board. The application of these new materials can enable the prepreg circuit boards to maintain stable performance under harsh environmental conditions, so as to adapt to the needs of high-power, high-frequency electronic devices. - Application of automation technology

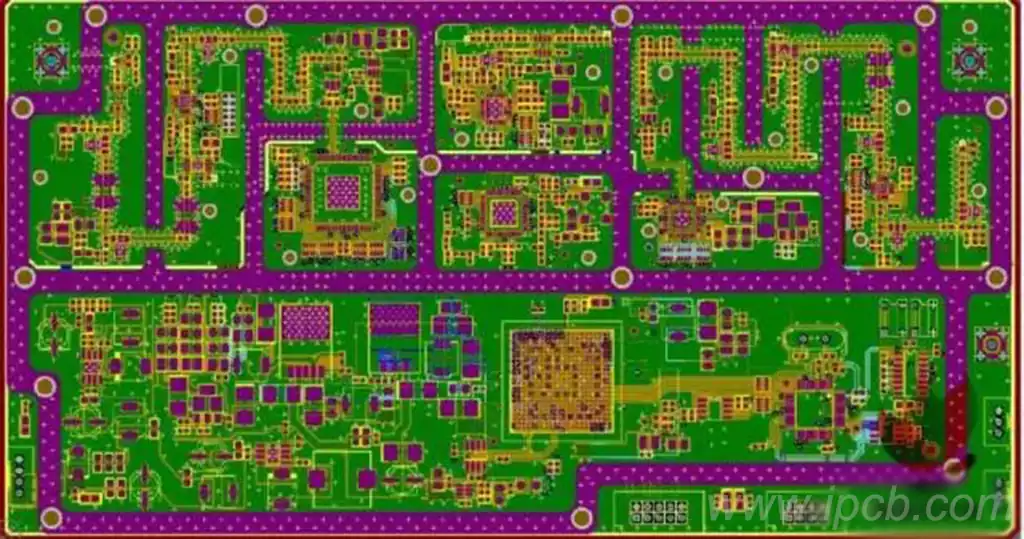

The introduction of automated manufacturing technology has significantly improved the production efficiency and consistency of prepreg boards. The use of automated lay-up machinery and laminating equipment not only improves the accuracy of the lamination process, but also reduces the errors brought about by human operation. This high-precision automation technology ensures the precise alignment of the prepreg and inner copper foil patterns, further improving the yield of multilayer PCBs. - Application of 3D printing technology

3D printing technology is gradually being applied to the manufacture of prepreg circuit boards, especially in the sample making and rapid prototyping stages. This technology is able to realize the complex structure of the circuit shape, reduce production costs and time. 3D printing flexibility allows designers to quickly iterate, making the product development process more efficient. - Intelligent Monitoring and Data Analysis

The introduction of intelligent monitoring systems and data analysis tools during the production of prepreg boards makes traceability and real-time monitoring of the production process possible. Through the analysis of production data, quality problems can be detected in time and the production process can be optimized. This intelligent management helps reduce scrap rates and production costs, while also improving product reliability. - Environmentally friendly production process

With the improvement of environmental protection requirements, the manufacturing process of prepreg pcb is also developing in the direction of green production. For example, solvent-free epoxy resins and recyclable materials are used to reduce the emission of hazardous substances in the production process. This is not only in line with the concept of sustainable development, but also meets the market demand for environmentally friendly products.

With its excellent dielectric properties, high strength and structural stability, good moisture resistance, compatibility and customizability, as well as its remarkable suitability for multilayer circuit boards, prepreg pcb has made them occupy an important position in the modern electronics manufacturing industry. In addition, with the introduction of emerging manufacturing technologies such as material innovation, automation technology, 3D printing, intelligent monitoring and environmentally friendly processes, the production efficiency and product quality of prepreg circuit boards have been significantly improved to meet the growing demands of the market. In the future, with further technological advances, the application scope of prepreg circuit boards will continue to expand, and its potential to promote the sustainable development of the electronics industry will also become increasingly evident.