A circuit board thermocouple connector is a device specifically designed to connect a thermocouple probe to a circuit board. It enables efficient transmission of temperature signals from the thermocouple to the measurement device and is widely used in temperature measurement and control systems. With this connector, accurate and reliable temperature monitoring can be achieved, ensuring system stability and safety.

The operating principle of circuit board thermocouple connector is based on the basic principle of thermocouples, which utilizes a circuit composed of two different materials. When one end of the connector is connected to the thermocouple probe, the different metal materials inside the connector form a closed circuit. When the temperature at the connection point is different from the temperature at the other end of the connector, an electric current is generated in the circuit, a phenomenon known as the Seebeck effect.

Seebeck Effect

The Seebeck effect is the core principle of thermocouple operation.When two conductors of different compositions are joined together and form a closed loop, if the temperatures of the two connectors are different,an electric potential is generated in the loop. This electromotive force is proportional to the temperature difference at the joints, allowing it to be converted to a temperature reading by an appropriate measuring device.

Temperature Measurement

Circuit board thermocouple connectors are capable of accurately measuring the temperature of the surrounding environment by transmitting the temperature signal from the thermocouple to the circuit board.When a temperature gradient exists between the ends of the connector, the current in the circuit causes changes in the electric potential, and the measuring instrument provides temperature data by reading these changes.This connection ensures the accuracy of the temperature signal during transmission and reduces the influence of external interference.

Structure and Connection

When designing the circuit board thermocouple connectors,the importance of minimizing thermal gradients is emphasized to improve the accuracy of temperature readings.The construction of the connector is usually designed to be soldered directly to the circuit board or connected via terminals to ensure optimum electrical contact and thermal conduction.This design ensures the generation of electric potential and the validity of temperature measurements.

Key Factors in Selecting Circuit Board Thermocouple Connectors

- Operating Temperature Range

The operating temperature range of the circuit board thermocouple connector is an important consideration in the selection process. Different types of thermocouple connectors have different temperature capabilities. For example,K-type connectors typically have an operating temperature range between -200°C and 1000°C,while T-type connectors range from -200°C to 300°C.It is critical to select the right connector for the intended operating environment. - Material Selection

The material of a connector directly affects its durability and reliability.Usually, high temperature resistant materials such as glass fiber filled nylon are used to improve the heat resistance and mechanical strength of the connector.Choosing the right material can ensure that the connector maintains good performance under extreme conditions. - Connection method

Circuit board thermocouple connector connection method is also very important.Different assembly methods (such as plug-in connection, threaded connection, etc.) for different application scenarios and equipment requirements.Ensuring that you choose a connection method that is compatible with the circuit board and thermocouple probe interface will help to achieve a more stable and reliable connection. - Electrical Performance

Electrical performance testing is a key part of ensuring connector stability and safety.This includes tests such as contact resistance, insulation resistance and voltage withstand to verify the connector’s performance under operating conditions.A good quality connector should have low contact resistance and high insulation to minimize the risk of heat generation and potential failure. - Cost and Supplier Reputation

Cost and manufacturer’s reputation are also factors that must be considered when choosing board thermocouple connectors. Reputable manufacturers usually provide higher quality products and excellent after-sales service.A good supplier is able to provide continuous technical support and quick response in case of failure, providing a better user experience.

Technical Challenges of Thermocouple Connectors in circuit board Designs

- Low Output Voltage and Sensitivity Issues

The output voltage of a thermocouple is typically very low, which makes the signal susceptible to noise interference during transmission. The low sensitivity of the output voltage requires that the connector be able to effectively transmit small electromotive force signals to ensure accurate temperature readings. Design needs to focus on the electrical properties of the connector to avoid measurement errors caused by poor contact or resistance. - Cold end temperature fluctuations brought about by the interference

Changes in cold end temperature can significantly affect the accuracy of thermocouple measurements.Such temperature fluctuations can result from changes in the environment around the device or from grounding problems at the thermocouple connection point.In order to minimize this effect, engineers need to take into account the issue of cold end compensation when designing circuit boards, which is critical to the overall performance of the connector.

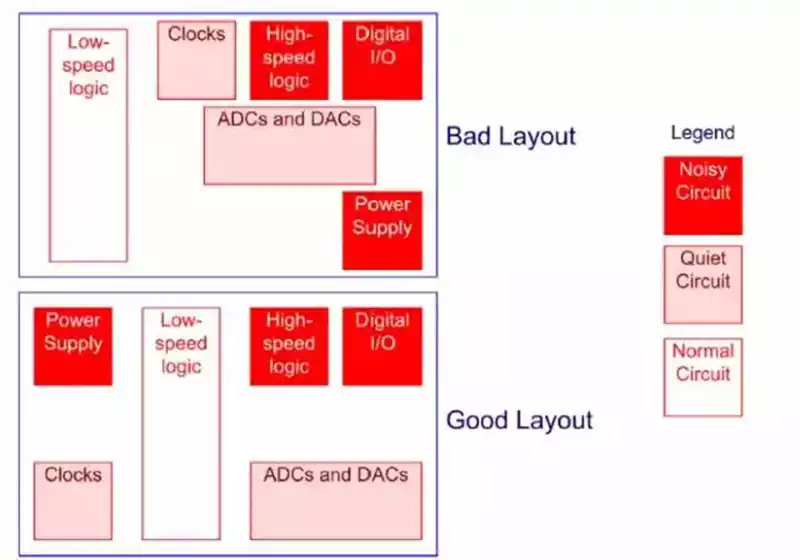

3.Reasonable PCB layout and structure design

Reasonable PCB layout and structure design is essential to eliminate external interference.Wrong wiring or improperly selected board layout structure may lead to unstable signal transmission and increased measurement errors.Therefore, in the design process,it is vital to reasonably plan the location and direction of signal lines to avoid the influence of electromagnetic interference.

- Reliability of thermal contact

Thermocouple connectors need to maintain good thermal contact with the PCB surface during operation.If the thermal contact is unstable,it will lead to a decrease in temperature measurement accuracy.Appropriate materials and structures need to be considered during design to ensure that the connector can maintain good thermal contact under various operating conditions. - Mechanical stress and durability

Thermocouple connectors must withstand challenges such as mechanical stress,temperature changes and environmental corrosion when operating in harsh environments.Connector material selection and structural design must ensure that it can still maintain reliable performance in long-term use, which requires designers to carefully consider the mechanical strength and durability of the material.

The operating principle of circuit board thermocouple connector relies on the seebeck effect,which converts temperature differences into electrical potentials, allowing for accurate temperature measurements.By efficiently connecting the thermocouple to the circuit board,the connector ensures accurate data transfer and is widely used in temperature monitoring systems in industry and laboratories.