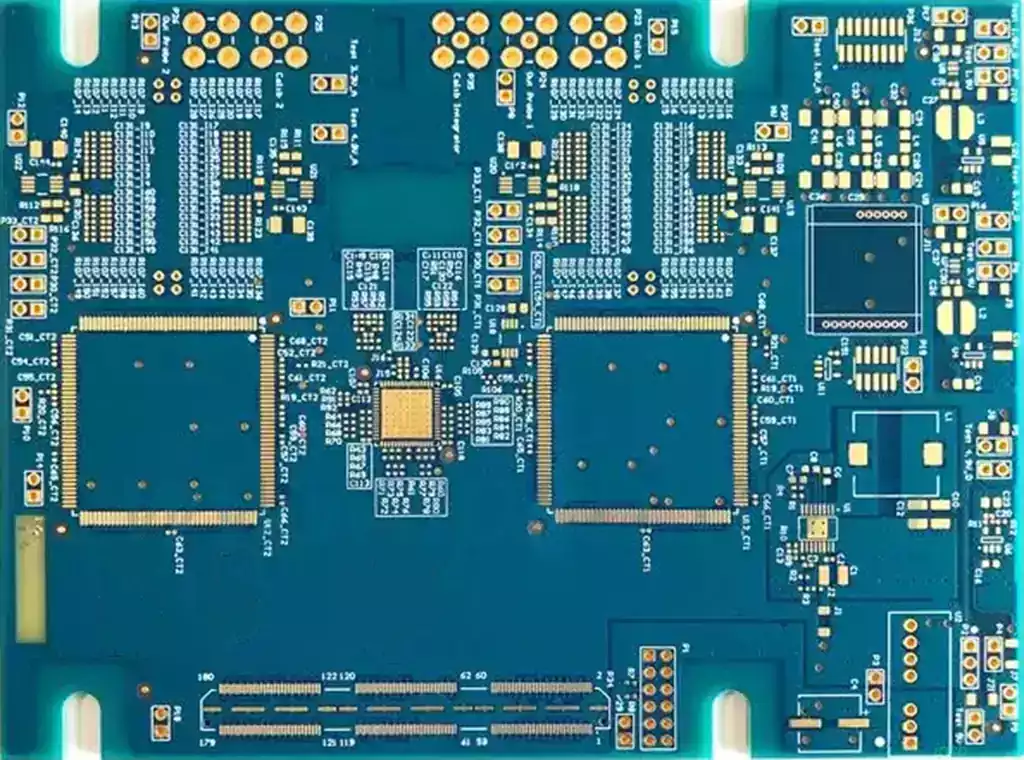

Within the physical infrastructure of electronic circuits, PCB circuit boards and FPCBs (flexible printed circuit boards) stand as the two core types supporting electronic components. Leveraging their distinct material properties and functional advantages, they span applications from traditional industrial equipment to cutting-edge consumer electronics. PCBs provide stable support through rigid structures, while FPCBs achieve breakthroughs in spatial layout via flexible substrates.

Substrate Characteristics

PCB Circuit Boards: Typically employ rigid substrates such as FR-4 glass fibre reinforced epoxy resin. This material endows PCB circuit boards with excellent stability and load-bearing capacity, making them suitable for fixing and supporting electronic components.

FPCB: Utilise flexible substrate materials such as polyester film or polyimide film. This flexibility enables FPCs to bend and fold, adapting to complex shapes and confined spaces.

Structure and Manufacturing Processes

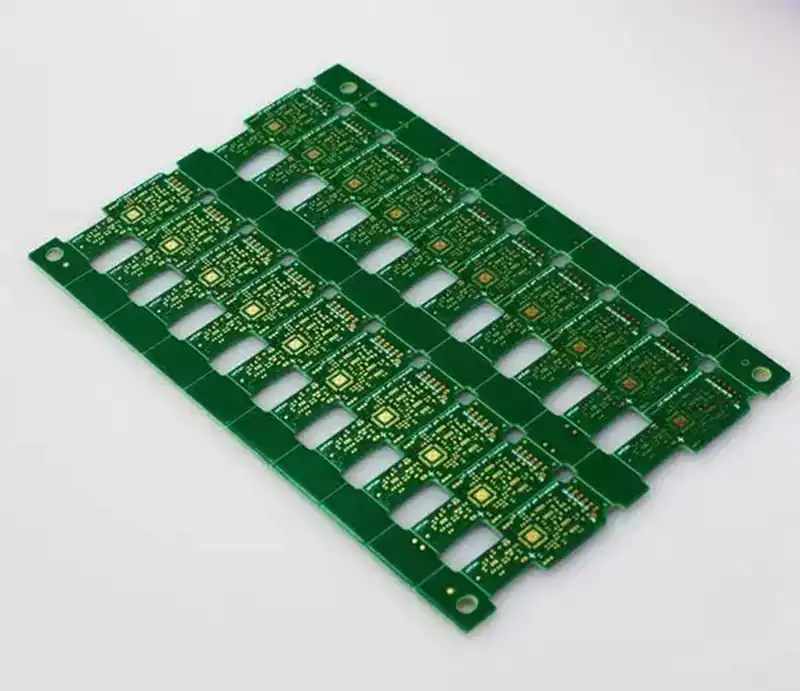

The production process for rigid PCBs is relatively mature and stable, encompassing multiple stages including layout design, substrate cutting, drilling, plating, and etching. Rigorous control of all process parameters throughout manufacturing is essential to ensure circuit board performance and reliability.

The manufacturing process for FPCB is more intricate, encompassing film material selection, circuit pattern formation, lamination, electroplating, etching, and subsequent assembly and testing. Given the heightened demands for flexibility and durability in FPCs, material selection and process control face stricter requirements.

Application Scenarios

PCB circuit boards find extensive application, playing a central role in fixed installations such as computer motherboards, home appliance control boards, communication base stations, and industrial control modules. They demonstrate unique advantages in high-density or high-frequency domains, including 5G base stations, AI servers, and new energy vehicle electronic control systems. Simultaneously, PCB circuit boards meet specialised requirements in heat-sensitive applications like LED lighting and electric vehicle IGBT modules.

In contrast, FPCBs are better suited for dynamic or space-constrained applications, such as foldable display flex cables in smartphones, drone gimbals, and wearable devices like smartwatches. The demand for thin and lightweight designs also relies heavily on FPC applications, including camera modules, battery connection cables, and medical endoscopes. Moreover, in cutting-edge innovation fields like AR/VR devices, flexible sensors for humanoid robots, and brain-computer interface signal transmission, FPC occupies an indispensable position due to its unique flexibility.

Rigid-flex boards, with their complex structural characteristics, excel in specific applications such as the hinge area circuits of foldable smartphones and automotive electronics requiring both fixation and bending.

Performance Differences

Temperature Resistance

PCB circuit boards exhibit superior high-temperature tolerance (FR4 withstands approximately 130°C), whereas FPCBs are constrained by their flexible substrates (polyimide around 260°C).

Signal Transmission

FPCBs exhibit lower signal loss at high frequencies (due to superior dielectric constant), making them suitable for 5G antennas and high-speed camera modules.

Weight and Thickness

FPCBs are over 70% lighter than PCB circuit boards and can achieve thicknesses below 0.1mm, ideal for miniaturised devices.

Cost and Reliability

Generally, FPCBs incur higher production costs than rigid PCB boards. This stems from the use of more expensive flexible materials and more complex manufacturing processes. Consequently, FPC flexible boards typically command a higher price point than rigid PCB boards. However, technological advancements and economies of scale are progressively reducing FPC flexible board costs.

Reliability

PCB circuit boards exhibit superior vibration resistance; FPCBs require consideration of flexural fatigue life (typically 10,000 to 100,000 bend cycles).

Hybrid Applications

Modern electronics frequently incorporate rigid-flex PCBs, integrating rigid and flexible sections within a single structure—such as the hinge area circuitry in foldable smartphones.

Maintenance and Repair

PCB circuit boards, owing to their rigid structure, are often difficult to repair once damaged. FPC flexible boards, however, may be easier to repair or replace in certain circumstances due to their flexibility. Furthermore, maintenance costs for FPCBs may also vary depending on material and design characteristics.

- Flexibility and Bendability

PCB Circuit Boards: Due to their rigid substrate, PCB circuit boards resist bending and deformation, making them suitable for electronic devices requiring stable support.

FPC Circuit Boards: Possessing excellent flexibility, they can be easily folded and bent, even allowing free arrangement of components and conductors in three-dimensional space. This makes them ideal for applications requiring bending or special shapes.

PCB circuit boards and FPCBs each possess irreplaceable technical value. The complementary strengths of rigid stability and flexible adaptability are driving electronic design toward greater efficiency and integration.