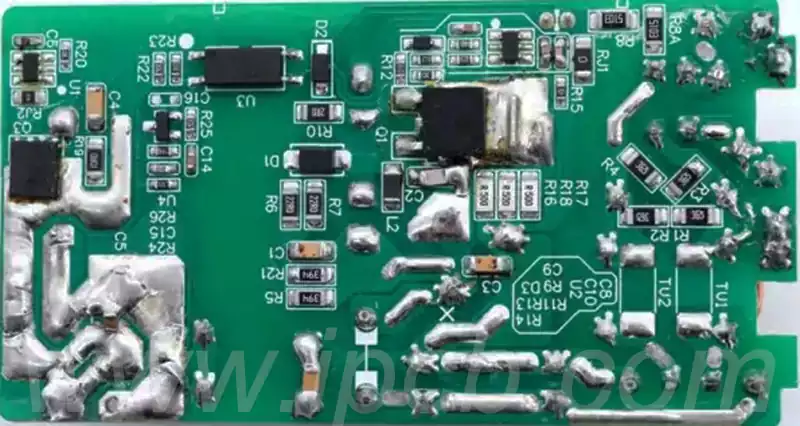

The hard drive printed circuit board is a key component of a hard disc. It consists of one or more layers of glass fibre substrates stacked on top of each other and covered with various electronic components, such as integrated circuits, connectors, capacitors, and so on. In the operation of a hard disc, the circuit board plays a central role in connecting and regulating the various components of the hard drive pcb.

The hard drive printed circuit board circuitry contains the following 14 core components

Buffer Memory

Interface Controller

Micro-processor

PRML Read Channel (Partial-Response Maximum-Likelihood Read Channel)

Timing ASICs

Servo Demodulator

Digital Signal Processor (DSP)

Preamp

Positioning Driver

Voice Coil Motor (VCM)

Magnetic Media Disk

Spindle Motor

Spindle Driver

Read/Write Heads (Read/Write Heads)

Buffers have several important applications in computer systems. For example, since the central processing unit (CPU) runs significantly faster than the hard disc drive (HDD), the data required by the CPU is first prefetched from the HDD into the buffer. At the same time, the CPU can perform other tasks in parallel so that when the data is loaded into the buffer, the CPU can access it at high speed, thus avoiding the loss of valuable CPU time waiting for the data.

The hard disc buffer plays a key buffering role in a computer system, between the other components of the computer and the physical hard disc platters used for data storage. The buffer manager splits the buffered random access memory (RAM) into separate buffer segments, and the microprocessor uses specific registers to store the addresses of these buffer segments for access operations. While the host is using one of the buffer segments for data exchange, the read/write channel can simultaneously use another buffer segment for data exchange. This mechanism allows the system to simultaneously handle multiple channels that read data from disk, write data to disk, or exchange data with the host, thereby increasing overall processing efficiency.

There are significant differences in the physical characteristics and usage patterns of the hard disc buffer and the page cache maintained by the operating system in the computer’s main memory: the hard disc buffer is managed directly by the microcontroller built into the hard disc drive, whereas the page cache is controlled by the computer system connected to the disc. In terms of capacity, hard disc buffers are relatively small, with modern hard discs typically equipped with buffer RAM capacities ranging from 16MB to 64MB; in contrast, page caches make use of main memory space that is not already occupied by other applications. In addition, data in the page cache tends to be frequently re-accessed and re-utilised, whereas data in the hard drive buffer rarely undergoes such re-use.

The interface controller serves as the connecting hub between the buffer, the host interface, the PRML read channel, and the microprocessor.Depending on the data interface, hard discs are broadly classified as ATA (also known as IDE), SATA, SCSI and SAS. It is worth noting that the interface speed is not the same as the actual transmission rate of the hard disc,the actual data transfer speed of the current ordinary hard disc generally does not exceed the limit of 300MB /s.The microprocessor plays an important role in the hard disc.

The microprocessor plays a central processing role in the hard disc,and its responsibilities include tasks such as executing firmware programs, following interface protocols (such as SATA or SCSI standards), regulating motor operation, deciding on data caching strategies, and managing bad block markers.

Think of the hard disc as a small computer system, with the SATA cable acting as the connecting wire that allows it to communicate with the ‘host’ computer. the CPU constructs information (e.g. SATA command packets) that tells the hard disc drive what data it needs and passes it through the cable to the drive. The processor inside the hard disc receives the information from the CPU and directs the drive’s motors and heads to perform the actual reading or writing of the data.

The drive’s microprocessor (or master controller) is based on a RISC architecture design. When the power is turned on, the drive’s reset circuitry sends a ‘reset’ signal to the microprocessor, prompting it to begin executing a self-test program stored in ROM. This procedure clears the operating data areas of the memory, the disc controller and other programmable chips connected to the internal data bus. The microprocessor then checks the internal signals required for the operation of the hard disc, and if it does not detect any emergency warning signals, it starts the spindle motor.

PRML (Partial-Response Maximum-Likelihood) read channel technology, designed to meet the challenge of increased recording density in storage devices. At lower recording densities, each write jump on magnetic media produces a more independent voltage peak, at which point peak detection technology can be used to effectively recover recorded information. However, as the recording density increases, a completely new detection method is required. Instead of relying solely on the voltage peaks, the reality of signal interference between neighbouring transitions must be taken into account.

PRML (Partial-Response Maximum-Likelihood) is the most widely used signal detection technique in modern disk drives. The concept of the technique was originally pioneered in the early 1970s by a group of researchers at IBM.

The PRML technique consists of two separate but tightly integrated components: the partial response (PR) system and the maximum likelihood (ML) detector. The partial response mechanism implies that part of the response to a single data bit may occur at one sampling time point, while the rest of the response may be spread over other sampling time points. The task of the maximum likelihood detector, on the other hand, is to find the one that best matches the read waveform from all possible bit patterns.

Digital signal processors (DSPs) play a central role in position control in hard discs. Although DSPs have a slightly higher initial cost than analogue design solutions, they offer superior performance and greater capacity. As hard drive printed circuit board has moved from analogue to digital position control, the cost of DSP chips has rapidly decreased, and today DSPs are integrated into the vast majority of hard disc circuits.

Positioning drives and spindle drives are often integrated into a single chip, the Servo/MSC Motor Speed Control Combination chip (Servo/MSC Controller Combination). The MSC stands for Motor Speed Control, meaning that the combined chip is responsible for both servo positioning control and motor speed control.

The spindle motor is the core component of the hard disc drive, and its operation is regulated by the spindle motor controller, which in turn is controlled by commands from the hard disc microprocessor. The operation of the spindle motor can be divided into three stages: start-up, acceleration and stabilisation. During the start-up phase, the microprocessor receives a reset signal when the power supply is switched on, which initialises the registers within the spindle motor controller. Subsequently, the HDD microprocessor issues a phase-switching command to rotate the spindle motor at a low speed, which in turn generates a self-induced electromotive force (EMF). Once the microprocessor detects this self-induced electromotive force, it adjusts the motor speed based on this signal. Once in the acceleration phase, the microprocessor increases the frequency of phase switching and continuously monitors the spindle motor speed until it reaches the preset rated speed. Once the spindle motor reaches the rated speed, it enters the stabilisation phase. During this phase, the microprocessor calculates the rotation period of the spindle motor based on the phase signal and fine tunes the speed accordingly. Once the heads are removed from the docking area, the hard disc circuitry continuously monitors rotational stability using servo markers.

The read/write heads are the key components of the hard disc that read and write data. The hard drive’s read/write channel system is complex in composition and includes key components such as a preamplifier/adapter (placed inside the platter cavity), read circuitry, write circuitry, and a synchronised clock. The preamplifier is designed as a multi-channel system with each channel connected to a magnetic head, and channel switching is precisely controlled by signals from the drive’s microprocessor. The preamplifier incorporates a switch for write current and a write error detection sensor, which triggers an error signal as soon as the head is short-circuited or broken.

In write mode, the integrated read/write channel receives the data to be written from the disc controller and simultaneously receives the write clock signal. This data is then encoded and pre-compensated before being precisely written to the disc via a preamplifier. And when the read/write channel switches to read mode, the signal from the preamplifier/adapter is fed into the automatic control circuit. After a series of delicate processing, including filtering by a programmable filter, compensation by a calibration compensation circuit, and signal conversion by a pulse detection circuit, the signal is finally transformed into data pulses. These data pulses are then sent to the disk controller for decoding before being transmitted out through the external interface.

The core function of the hard drive printed circuit board:

- Command the data reading and writing activities of the hard disc: the controller chip on the hard drive printed circuit board plays the role of the overall command of the hard disc reading and writing operations. It receives commands from the computer and converts these commands into electrical signals, which are then accurately conveyed to the magnetic heads and discs through connectors, thus accurately completing the process of reading and writing data.

- Constructing a communication bridge between the internal components of the hard disc: The hard drive printed circuit board is cleverly laid out with a number of connectors, which act as a high-speed channel for information, linking key components such as the spindle motor, the head motor and the magnetic head closely together. These connectors ensure the smooth transmission of signals between components and the accurate execution of control commands through a precise network of wires.

- Power regulation and management: The voltage and current management module on the circuit board is the core of hard disc power supply and management. It not only ensures the stable supply and adaptation of the hard disc power supply, but also through its advanced power management functions, to achieve the hard disc’s energy saving and automatic hibernation mode, to further enhance the performance of the hard disc’s energy efficiency.

Hard drive printed circuit board application technology field:

Data salvage technology: In the event of a hard drive pcb failure, valuable data can be recovered with the help of data salvage technology. This technology relies on specialised data salvage software and hardware devices.

RAID (Redundant Array of Independent Disks) Architecture: RAID architecture is a highly efficient data storage solution that integrates multiple hard disks into a single logical hard drive, thereby significantly increasing data security and reliability. The implementation of RAID technology requires a professional RAID controller and hard drive pcb.

SSD (Solid State Drive) Technology: SSD technology represents an innovative storage model that significantly improves hard drive read/write efficiency and data transfer speeds. SSD technology relies on professional SSD controllers and matching hard drive printed circuit board.

The importance of hard drive printed circuit board, the cornerstone of data storage technology, cannot be overstated.From data recovery to high-efficiency storage solutions to innovations in solid state drive technology, the hard drive pcb continues to drive the development of data storage technology.Looking to the future,it will continue to play a key role in the field of data storage, leading us towards a new era of smarter and more efficient data storage.