Electronic Manufacturing Services (EMS) refers to the testing, manufacturing, distribution, and return/repair services of electronic components and assemblies provided to a company by an Original Equipment Manufacturer (OEM). The concept is also known as Electronics Contract Manufacturing (ECM).

The EMS industry originated in the late 1970’s when most electronics manufacturing and large products were assembled primarily in-house.The EMS industry business model focuses on economies of scale, sourcing of raw materials and centralized resources, specialized solutions for industrial design, and provision of value-added services such as warranty and maintenance. This helps to free up customers who have large inventories. As a result, PCBA (Printed Circuit Board Assembly) is able to respond faster and more efficiently to sudden spikes in demand.

The advent of Surface Mount Technology (SMT) and Printed Circuit Boards (PCBs) has led to a dramatic increase in the speed of assembly of electronic products. By the early 1990s, OEMs were rapidly introducing SMT lines. By the mid-1990s, the benefits of the EMS concept became apparent and OEMs began outsourcing printed circuit board assembly (PCBA) on a large scale. By the late 1990s and early 2000s, many OEMs sold their assembly plants in order to compete for market share with EMS companies. A wave of industry consolidation followed as cash-rich companies quickly acquired existing plants and smaller EMS companies.

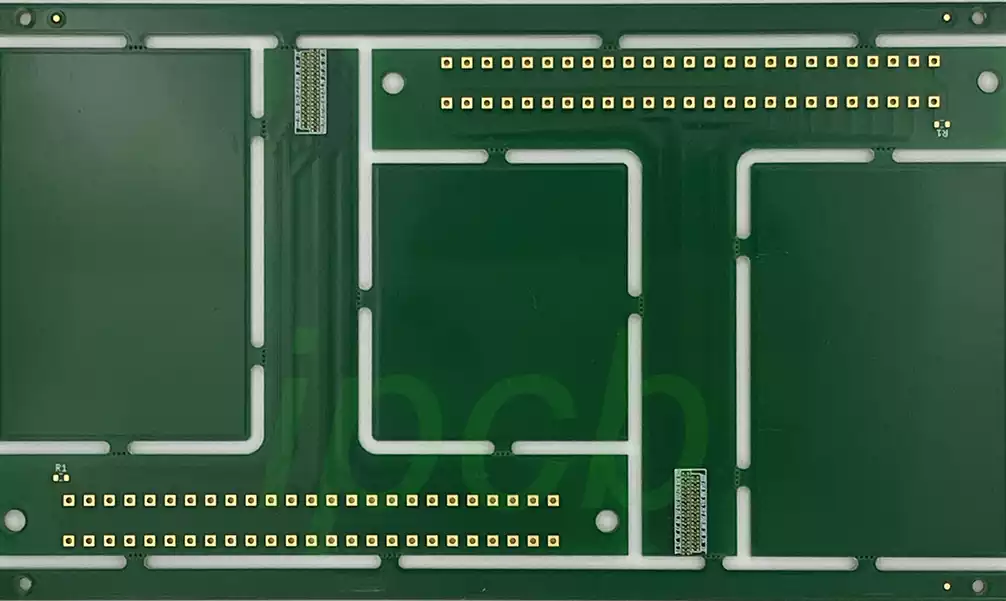

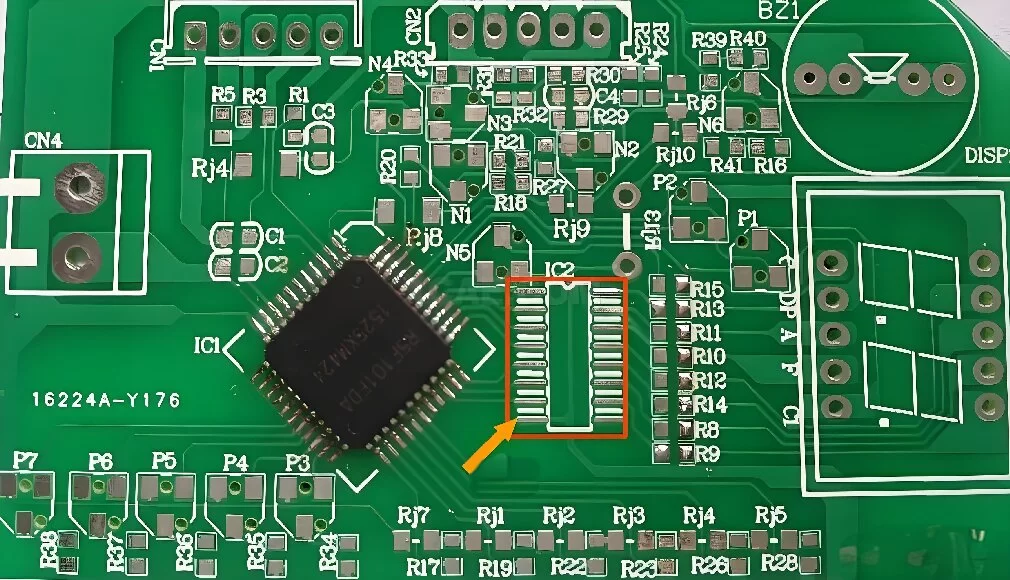

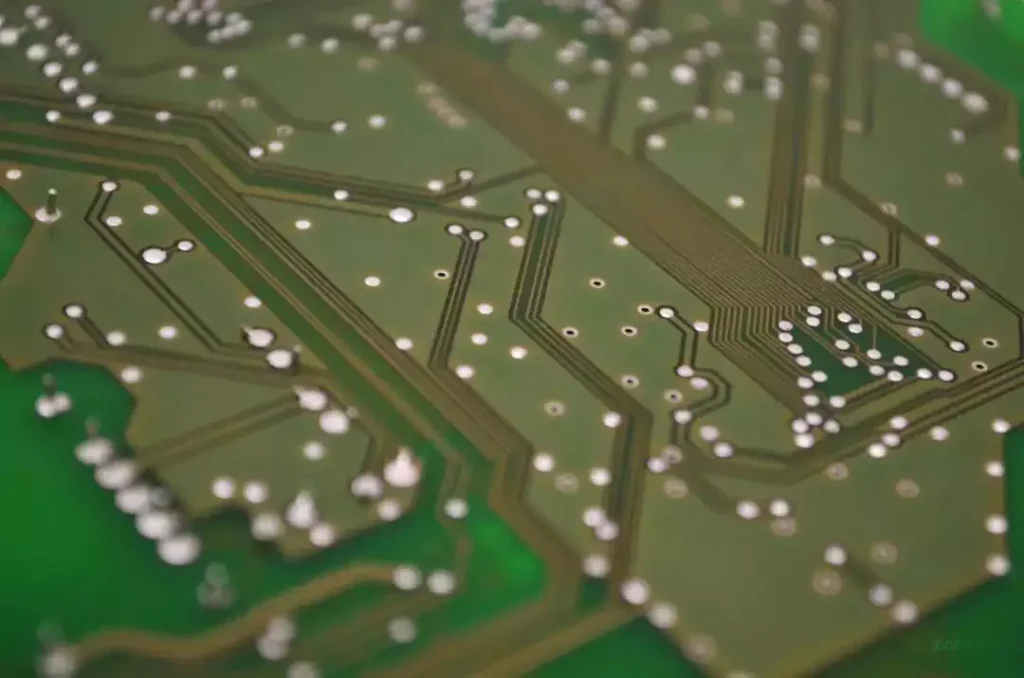

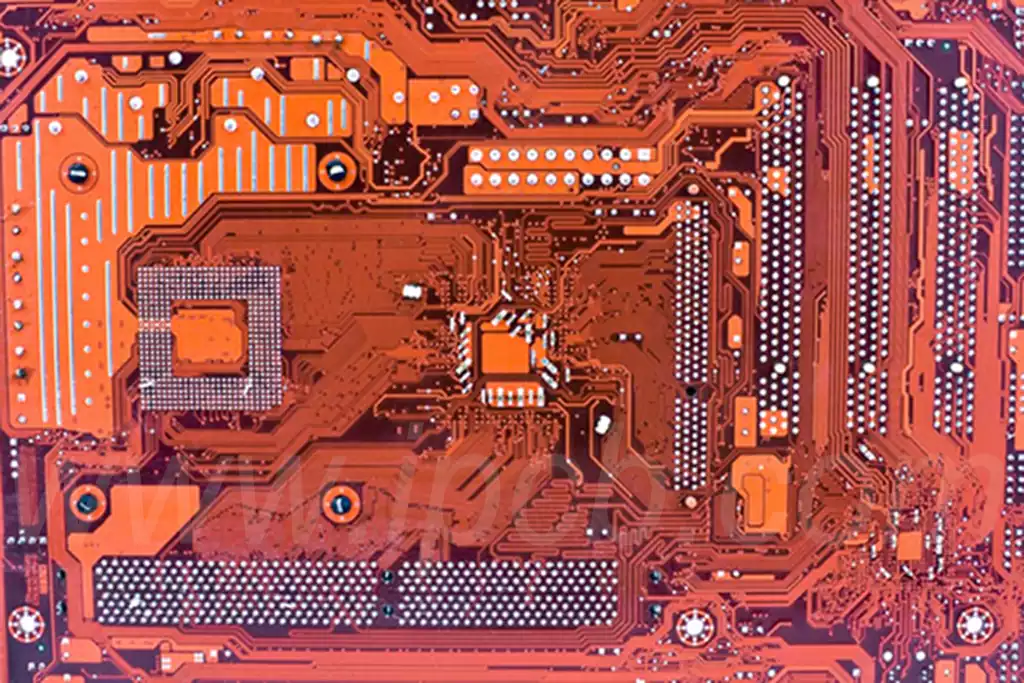

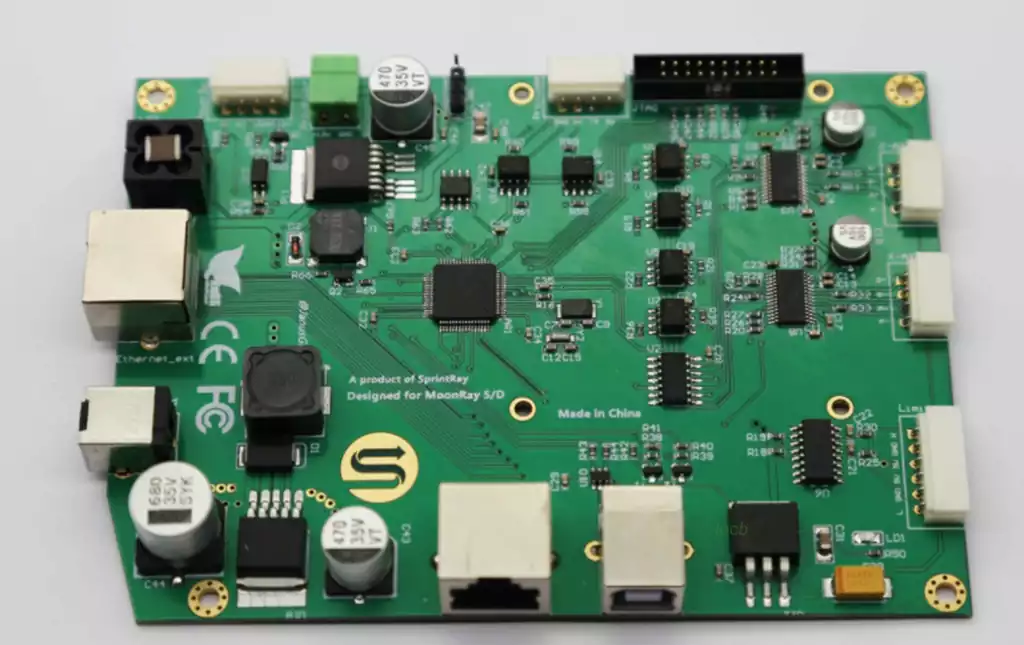

Printed circuit boards, also known as PCBs (Printed Circuit Boards), are important supports and circuit connection providers for electronic components. Because of the use of electronic printing technology, so the name “printed” circuit boards. PCBA, that is, the abbreviation of Printed Circuit Board Assembly, in short, by the SMT chip processing, DIP plug-in processing and PCBA testing and so on a series of processes composed of a number of processes.

SMT chip processing mainly refers to the process of processing electronic components on the bare PCB board, including PCB board printing solder paste, component placement, reflow soldering, manual soldering, AOI inspection and quality department quality inspection and other manufacturing processes. Subsequent to the DIP plug-in processing, that is, the electronic components can not be mounted plug-in processing, and after the wave soldering, cutting foot quality inspection and other processes. At this point, most of the PCBA processing has been completed. Finally, it is necessary to test and burn the program to complete the whole process.

EMS actually covers OEM and ODM, and OEM and ODM include PCBA, therefore, PCBA process is actually an important part of EMS. Compared with PCBA, EMS is more difficult, more complex, and requires a higher technical foundation.