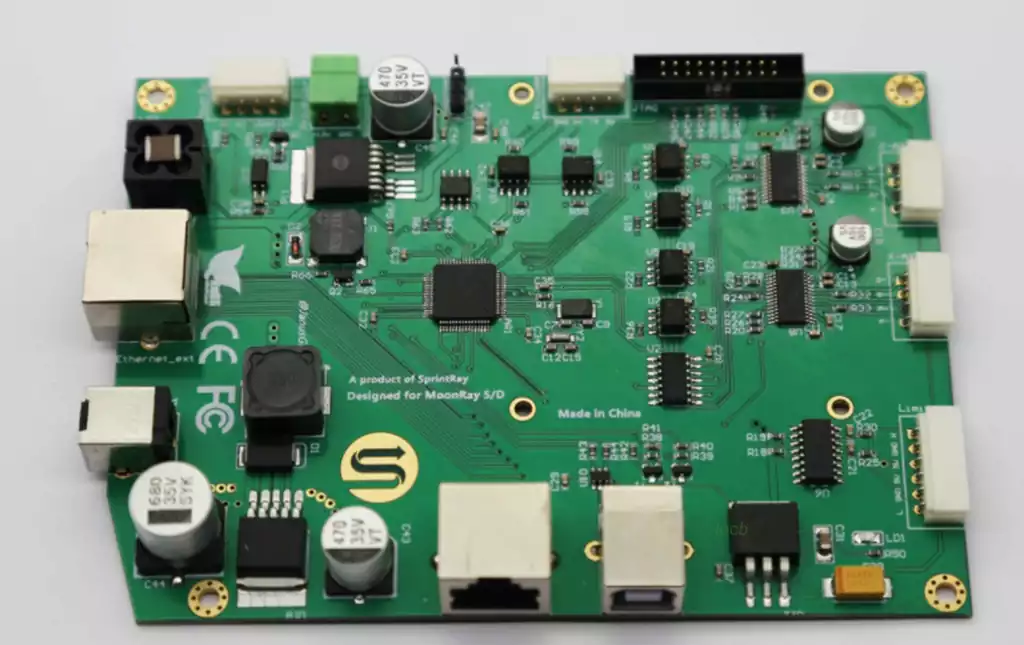

What is fct? It refers to a test method that provides a simulated operating environment (excitation and load) for a test target board (UUT: Unit Under Test) to operate in a variety of design states, so as to obtain the parameters of each state to verify the functionality of the UUT. Simply put, the UUT is loaded with appropriate excitation and the output response is measured to see if it meets the requirements. Generally refers to the PCBA function test.

Function test according to the different control modes, can be divided into manual control function test, semi-automatic control function test, fully automatic control function test. The earliest function test, mainly manual and semi-automatic mode. For some simple boards under test, based on the simplification of design and reduce production costs, we sometimes still use manual or semi-automatic test program. With the development of science and technology, in order to save production costs, the majority of functional tests are fully automated programs. Another more common classification is based on the type of controller used for functional testing. In function testing, we usually use MCU control, embedded CPU control, PC control, PLC control and so on.

PCBA function test regardless of what kind of test mode, the system results are mainly divided into the following parts:

- System control center:

This part is generally PC, MCU, ARM and other small or medium-sized central processor composition, its main role is to control the process of the entire testing process, and each step of the test content of the judgment and records, and ultimately the test results. It is the core brain of the whole test system. - Control execution part:

The control execution part is mainly composed of I/O electronic components, which is the sensing and actuating agency of the logical action of the test process. The system builds various test environments through it to realize the test functions.

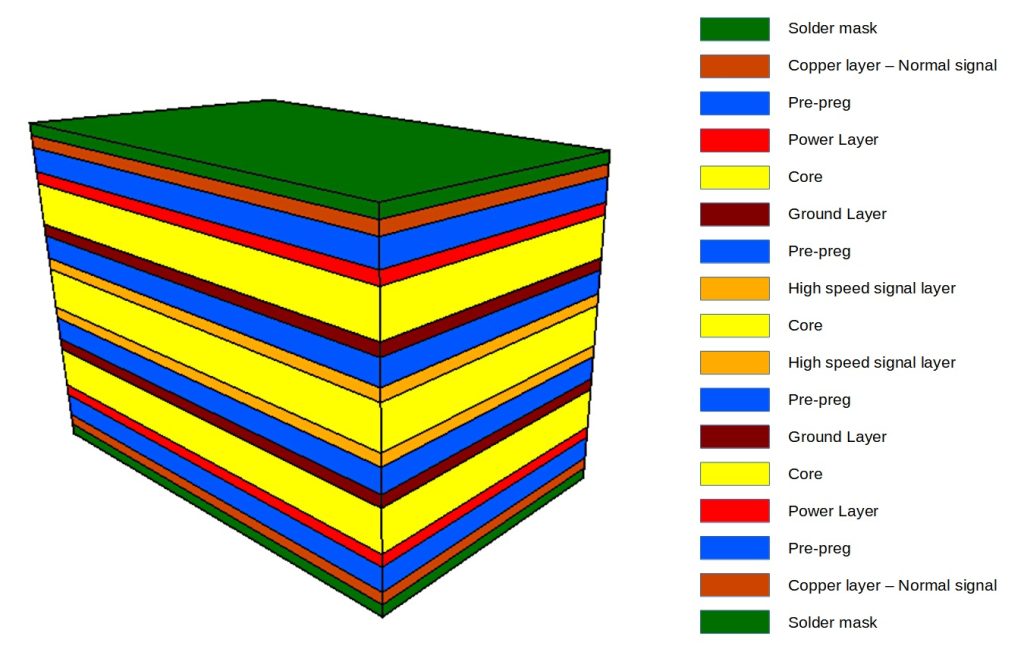

FCT test fixture is used to test components (capacitance / inductance / resistance) parameters, as a common small passive device, but affects the parameters of the circuit, but also directly involved in the merits of electronic products. In general, the resistor can be measured as long as its DC resistance value, so that you can use a multimeter or resistance tester, in addition to the DC resistance measurement function. Unlike ordinary resistance, inductance and capacitance need to be measured in AC mode, and FCT test fixtures use AC power for measurement. The resistance R in DC mode is simply expressed in terms of ‘magnitude’, whereas the impedance Z does contain two elements, ‘magnitude’ and ‘phase’, which are mathematically expressed in terms of complex numbers and vectors.

When using FCT test fixtures, the following points should be noted.

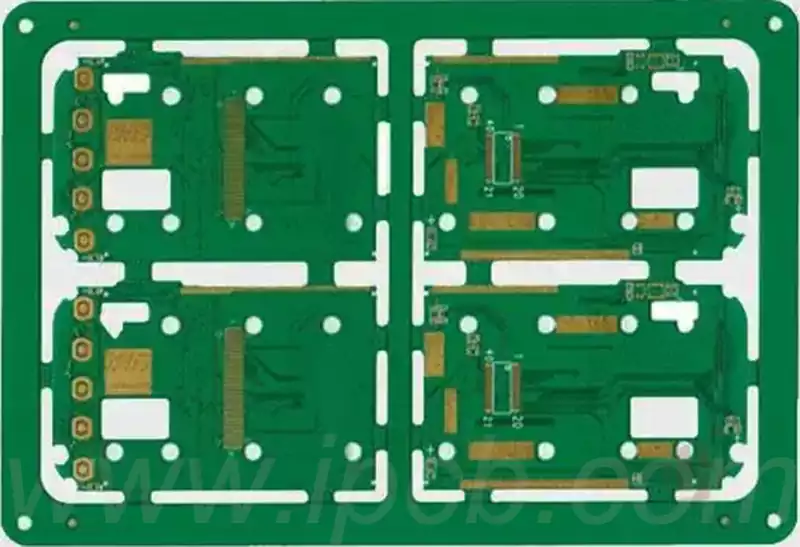

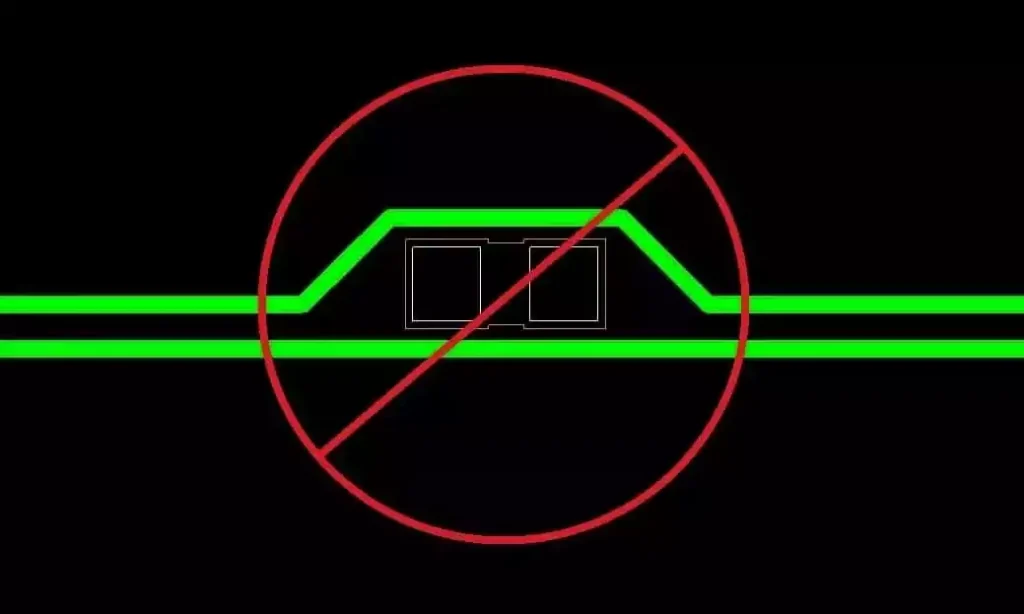

- Select the appropriate measurement fixture. Measurement fixtures are also an important part of FCT test fixtures. For components with diverse packaging methods, LCR also has a variety of measurement fixtures to choose from. The following are the LCR test fixtures and measurement ranges. Appropriate measurement fixtures not only bring the convenience of measurement, but also to ensure the accuracy of measurement.

- Correct zero calibration, the zero drift of FCT test fixtures will change with the change of test conditions or different test fixtures, so the zero calibration of open circuit and short circuit is very necessary, so there are open circuit and short circuit calibration settings.

- Select the correct test conditions. The device parameter values given by the component manufacturer represent the performance that can be achieved under the specified measurement conditions, as well as the permissible deviation values.

Functional Circuit Testing (FCT), as a key part of electronic product quality control, provides a solid guarantee for the reliability of electronic products. With the continuous development of electronic technology and changes in market demand, this test technology will also continue to innovate and improve, contributing to the quality assurance of electronic products and the enhancement of user experience.