LED control board is a kind of electronic circuit board used to control light-emitting diodes (LEDs). Its main function is to control the brightness, colour and flashing mode of LEDs by adjusting the power supply and signal. LED control boards are widely used in various types of lighting equipment, display screens, advertising boards and other electronic products.

The main working principle of LED control board and its components

Power Management

LED control board needs to be connected to a power supply to provide the necessary power for the LEDs. The power management system of the control board is responsible for converting the input voltage (e.g. from AC power or DC power) into a voltage and current suitable for the LED’s operation.The LED’s operating voltage is usually low, so the control board is designed with a voltage regulator circuit to ensure that the LEDs operate within a safe range, preventing damage due to over-voltage or over-current.

Driver Circuit

The LED driver circuit is the core part of the control board, which is responsible for regulating the current flowing through the LEDs.The driver circuit usually uses a switching power supply or a linear regulated power supply to provide the proper current for the LED according to its characteristics. The appropriate current can not only maintain the normal light emission of LED, but also extend its service life.

Control Signal Processing

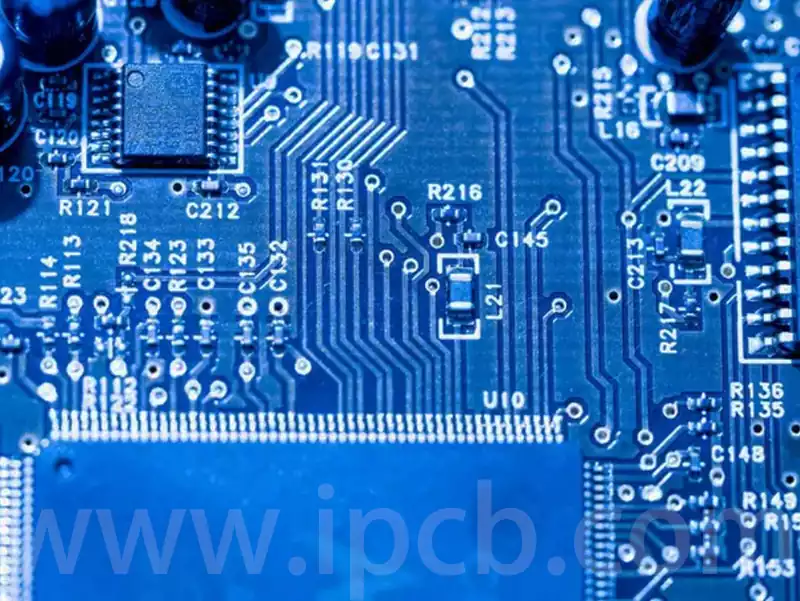

The microcontroller or microprocessor in the control board is the intelligent core to realise the lighting effect. It receives signals from the control interface, such as the user’s key input or remote control signals. According to the received information, the microcontroller will develop the corresponding control strategy. The processing of control signals includes the following aspects:

Brightness Adjustment: Brightness changes are achieved by adjusting the current level of the LED.This is usually achieved by pulse width modulation (PWM) technology, which changes the brightness of the LEDs by rapidly switching them on and off: the higher the duty cycle, the brighter the LEDs, and vice versa.

Colour mixing: In RGB (red, green and blue) LEDs, the led control board controls each colour independently and achieves different colour effects by adjusting the current for each colour. By mixing the three colours proportionally,colourful lighting effects can be generated.

Communication Interface

Modern led control board is usually equipped with a variety of communication interfaces, such as DMX512, SPI, I2C or wireless connections (e.g. Bluetooth or Wi-Fi). These interfaces are used to enable data transfer between the control board and other devices such as consoles, computers or smartphones. These interfaces allow the user to control lighting effects remotely or by preset for dynamic changes and scene switching.

Output to LED

After processing the LED driver and control signals, the control board outputs the final control signals to the LEDs, a process in which the output current is adjusted in real time to ensure that the LEDs emit light at the set intensity and colour. This process involves precise current regulation and response speed to achieve the lighting effect expected by the user.

LED control board is used in many fields, including:

Advertising and signage:for shop signboards and billboards to attract customers’ attention through dynamic lighting effects.

Stage Lighting: in concerts and performances to control light brightness and colour to create different visual effects.

Backlight Display: Used for backlight operation of LCD TVs and displays to adjust brightness and contrast to enhance the display effect.

Smart Home: In home lighting system, to achieve intelligent control and automated management.

Communication interface type of LED control board:

1.DMX512

DMX512 is a digital communication protocol widely used for stage lighting and effect equipment control.It allows multiple devices to be controlled via serial communication, and is typically used for systems that require a fast response,such as performances and light shows.Each DMX512 control signal can control multiple channels and is suitable for complex lighting control needs.

2.SPI (Serial Peripheral Interface)

SPI is a serial communication protocol for fast data transfer. It is commonly used to connect microcontrollers to peripheral devices and supports full-duplex communication. Due to its simplicity and efficiency, SPI is widely used for RGB LEDs and other types of LED control.

3.I2C (Inter-Integrated Circuit)

I2C is a bi-directional, half-duplex serial communication protocol, commonly used in the control of a variety of devices and data acquisition. It is capable of connecting multiple devices over two wires, making it easy to use in small circuits and simple applications.I2C is suitable for low-speed device communication and is often used for basic dimming and control functions in LED control.

4.RS232/RS485

RS232 and RS485 are serial communication standards typically used in industrial and commercial applications. They are able to communicate reliably over long distances. RS485 supports multi-point communication and is suitable for application scenarios that require long distances and multiple device connections. RS232 is suitable for shorter distance applications and is commonly used for simple device control.

5.TTL (Transistor-Transistor Logic)

TTL is a logic level interface for short distance digital signal communication, often used for direct connection with microcontrollers or other digital circuits. In LED control, TTL signals are often used to implement simple control functions.

6.Wi-Fi/Bluetooth

In recent years, wireless communication interfaces based on Wi-Fi or Bluetooth have become increasingly popular in smart home and lighting systems. These wireless communication interfaces allow users to control remotely via mobile devices for flexible applications and intelligent management. LED control panels that support this communication are mostly used for home, commercial and architectural lighting.

7.CAN (Controller Area Network)

CAN is a communication protocol used for automotive and industrial equipment, mainly used to connect a variety of electronic control units (ECU). Although it is not as common as the above interfaces in LED control board, it may also be used in certain multifunctional devices and systems.

LED control board plays an important role in lighting, display and other fields with their precise control, diverse functions and wide range of applications. With the continuous progress of technology, the richness of communication interface types and the development of intelligent trend, LED control board will continues to bring users more flexible and efficient control experience and promote the continuous development of related industries.