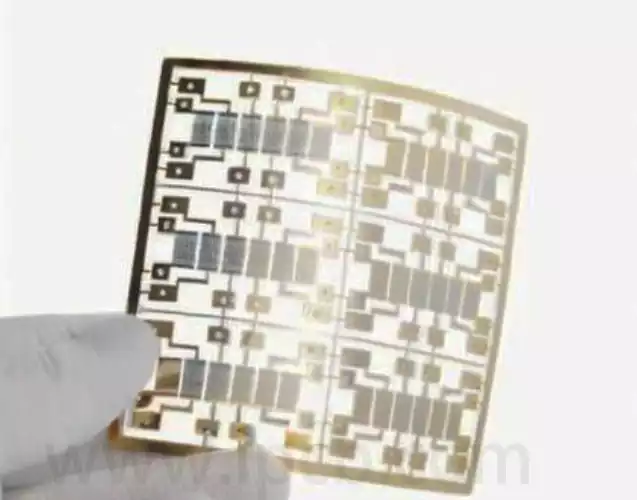

A transparent flexible PCB is a pcb board that can be bent and has a certain degree of flexibility without affecting its functionality. It is made of flexible materials such as polyimide or polyester film, allowing for compact circuit connections in a given space. Transparent flex pcb is lightweight and durable. It is this property that provides design versatility for devices with irregular or moving parts. They increase the reliability and longevity of PCBs by reducing wiring complexity and vibration damage. Transparent FPCs can be single-sided, double-sided or multilayered to meet a variety of electrical requirements.

Main Application Areas of Transparent flex pcb

- Transparent flexible pcb is increasingly used in flexible display technology, especially in OLED (Organic Light Emitting Diode) displays. Its transparency allows the screen to display images while allowing the content behind it to be visible through the screen.

- Transparent flexible pcb is also very important in the application of touch panels, especially those devices that require a transparent conductive layer, such as smart phones, tablets and car navigation systems.

- Transparent flexible pcb can be used as transparent antennas, which are widely used in wireless communication devices that require invisible mounting, such as antennas on car glass and antennas in smart windows.

- Applications of transparent FPC in wearable devices include smart watches, smart glasses and health monitoring devices. Its transparent and flexible features enable it to fit closely to the surface of the human body and not affect the appearance of the device.

- In smart home devices, transparent flex pcb is used in various smart control panels and displays, such as smart mirrors and smart windows.

- Transparent FPC is widely used in optical devices, such as camera modules, projectors and laser devices. Its transparency and high-precision conductivity enable it to meet the special requirements of optical devices.

- In medical equipment, transparent FPC is used in transparent biosensors, X-ray imaging equipment, etc.. These devices require transparent circuits for light transmission or signal transmission.

- Transparent FPC is used in automotive electronics including head-up displays (HUD), in-car displays and smart windows. Its transparency and durability enable it to cope with the demanding environment inside the car.

Transparent Flexible Printed Circuit Boards are an innovation in today’s electronics. They have become very popular in a short period of time and have been deployed in many areas. There are some key aspects of the manufacturing and assembly process for Transparent Flexible PCBs that need to be considered at the design and manufacturing stage.

Key Design Aspects

The design portion of any PCB is always critical from a manufacturing perspective. The design activity for transparent flexible PCBs is further complicated by the fact that they have a wide range of electrical and optical characteristics. Maintaining the electrical aspects of the circuitry along with the visual characteristics needs to be carefully considered. In addition, the PCB must be designed for good aesthetics and functionality with signal integrity.

Transparent Material Selection

The fabrication and assembly of transparent flexible PCBs requires suitable materials with both transparent and electrical properties. Materials used in normal PCBs and flexible PCBs are not suitable for transparent flexible PCBs. Transparent flex PCB materials should be compatible with the conductive materials in the PCB design. The visual and optical properties of the material should comply with user acceptance criteria. The material should be reliable under critical and stressed conditions.

Complex Manufacturing Processes

PCB substrates combine flexibility, transparency, and conductivity, so the manufacturing process requires precise and skilled techniques. In order to obtain high-quality transparent and flexible PCBs, great care must be taken at every step of the layer alignment and component placement process. Misalignment of the inner layers and confusion in the alignment of the components can lead to poor display output.

High-end costing

The core materials for transparent flexible PCB is themselves more expensive than normal and flexible materials. Manufacturing PCBs with transparent conductive substrates in flexible circuit boards requires high-tech machinery and precise process parameters. The total cost of the Transparent Flexible PCB product increases due to expensive machines, high production costs and difficult processing.

Due to the special characteristics of transparent flexible PCB, it has great potential for development in the short term. In the future, there will be transparent PCB materials that have excellent performance under harsh conditions and are compatible with electronic PCB components. With continuous research on transparent PCB materials and overcoming manufacturing process barriers, transparent flex PCBs have been integrated into today’s applications and products. Nanofibres offer a promising solution for the preparation of high-performance flexible transparent electrodes. However, there are still many issues that need to be investigated in order to meet the requirements of high performance and industrial production of future flexible devices, such as performance optimisation and trade-offs, industrial and efficient production, compatibility with multifunctional applications, and sustainability.