During the PCBA processing process, some electronic components with poor welding are often encountered. Desoldering is required during the adjustment and maintenance process, or when electronic components are replaced due to incorrect welding. In the face of such electronic components, we generally remove the wrongly welded electronic components without damaging the PCB board. If the desoldering method is not good, it will cause damage to electronic components, rupture of printed circuit boards or fall off of pads.

Excellent desoldering technology can ensure the smooth progress of adjustment and maintenance work, and avoid increasing the product return rate due to illegal replacement of components.

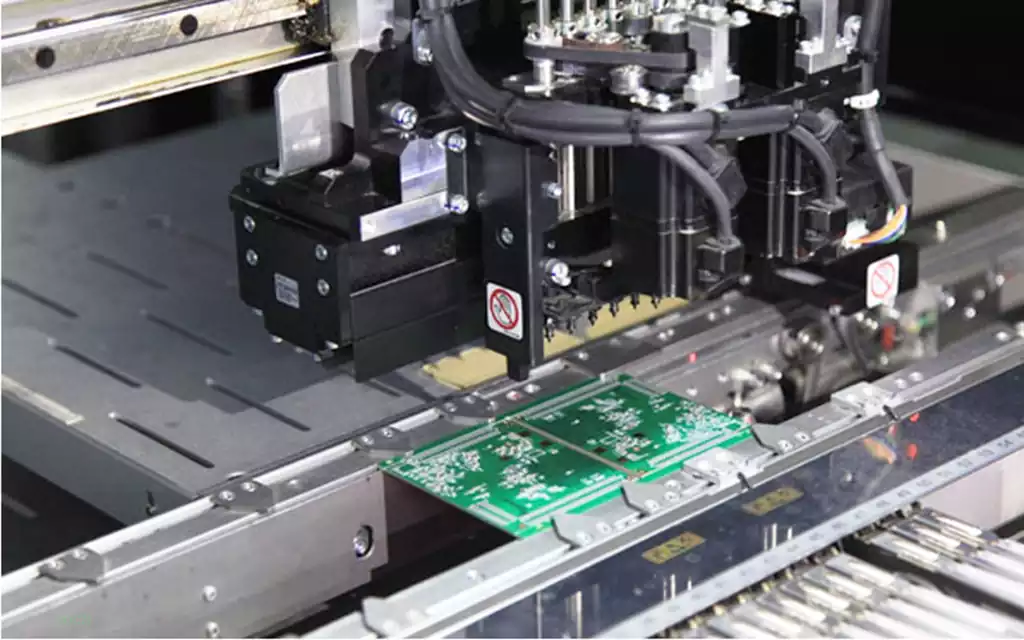

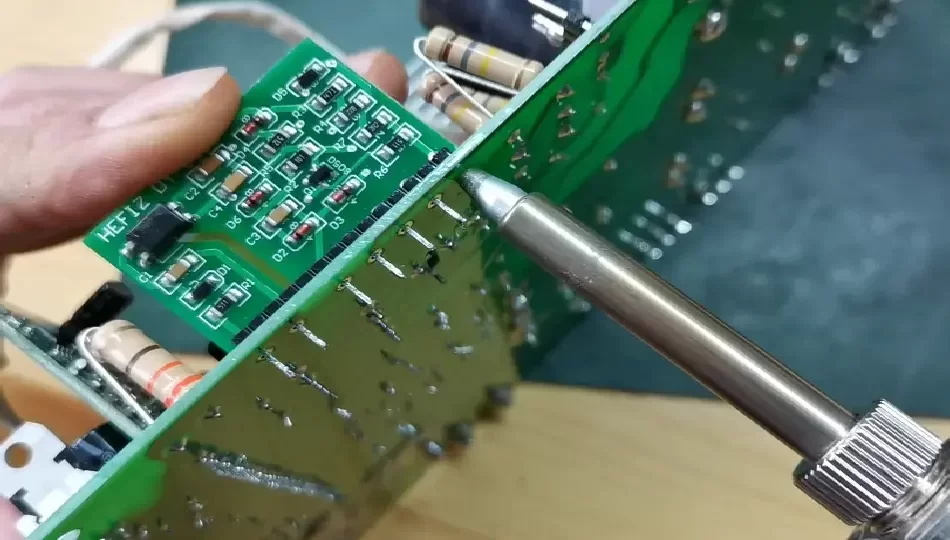

desoldering circuit board

Desoldering Preparation:

Before desoldering a circuit boards, it is crucial to make adequate preparations, which can ensure the smooth operation and minimize potential damage. Clean work area: Operate on a clean and spacious workbench to ensure that the surface is clean and tidy. Remove debris and debris to ensure that you have enough space and a comfortable working environment. Prepare the necessary tools and materials: Make sure you have the appropriate tools and materials to disassemble the circuit board. Commonly used tools include soldering iron, desoldering machine, tweezers, tweezers, safety glasses, anti-static equipment, etc. In addition, prepare some solder suction wires, solder suction pumps or tin suckers for removing solder.

Check the circuit board: Carefully inspect the circuit board to be disassembled to see if there is any obvious damage or destruction, as well as problems that may affect the disassembly process. If so, you need to consider how to deal with these problems in advance.

Safety measures: Make sure to take necessary safety measures when performing operations, such as wearing appropriate personal protective equipment such as safety glasses and protective gloves to prevent injury. In addition, make sure the work area is well ventilated to avoid inhaling welding fumes.

Familiar with the circuit board layout: It is best to be familiar with the layout and connection methods of the circuit board before starting to disassemble. If possible, check the schematic and layout diagram of the circuit board to understand the location and connection methods of the components, which will help to better understand the disassembly process.

Back up important data: If the circuit board stores important data, such as firmware or configuration information, make sure to back up this data in advance to prevent accidental loss.

Tips for circuit board desoldering

Electronic components on circuit boards are usually small and closely aligned with each other, so it is necessary to use the appropriate tools in order to remove them. In general, the following tools are required:

- constant temperature soldering iron: to ensure that it is not overheated to avoid damage to the components.

- solder sucker: to suck out the excess melted solder.

- Tweezers: to facilitate the extraction and insertion of electronic components.

- wire strippers: to facilitate the cutting of wires on the circuit board.

Master the correct method of desoldering

- Remove the solder: use a constant temperature soldering iron to heat up to the solder melting, and then use the solder sucker to suck off the melted solder.

- Take out the electronic components: use tweezers to gently pull out the electronic components, to avoid the use of too much force resulting in component breakage. When pulling out the components, you can use wire strippers to gently press into the soldering pins on both sides to push out the components from the circuit board.

- Clean the solder joints: Use cotton cloth or other cleaning tools to clean the solder joints in order to solder new components.

(1) Point desoldering method: For horizontally mounted resistors and capacitors, the two solder joints are far apart. You can use an electric soldering iron to heat the points and pull them out one by one. If the pins are bent, pry them straight with the soldering iron tip before removing them. When desoldering, stand the PCB upright, heat the pin solder joints of the components to be removed with a soldering iron, and use tweezers or needle-nosed pliers to hold the pins of the components and gently pull them out.

(2) Concentrated desoldering method: Since the pins of the resistor array are soldered separately, it is difficult to heat them all at the same time with a soldering iron. You can use a hot air soldering machine to quickly heat several solder joints and pull them out at once after the solder melts.

(3) Retention desoldering method: Use a tin-absorbing tool to absorb the solder of the solder joints to be removed. In general, the components can be removed. If you encounter multi-pin electronic components, you can use an electronic hot air machine to heat them.

If it is a lap-soldered component or pin, you can apply flux on the solder joint, use a soldering iron to open the solder joint, and the pin or wire of the component can be removed. If it is a hook-soldered component or pin, first use a soldering iron to remove the solder from the solder joint, then use the soldering iron to heat it to melt the residual solder under the hook, and at the same time, use a spatula to lift the pin in the direction of the hook line. Do not use too much force when prying to prevent the melted solder from splashing into your eyes or clothes.

(4) Cutting off the soldering method: If there is excess on the component pins and wires on the desoldering point, or if it is determined that the component is damaged, you can first cut off the component or wire, and then remove the wire ends on the pad.

Desoldering Notes:

Safety first: Make sure to wear appropriate safety glasses and gloves when performing desoldering work to protect yourself from heat and solder damage.

Avoid static electricity: When handling electronic components, be sure to avoid static electricity, use anti-static equipment or avoid operating in a static environment.

Control temperature: The temperature of the soldering iron should be moderate. Excessive temperature may damage the circuit board or components. Adjust the temperature according to the requirements of the components and solder joints.

Handle carefully: When removing components, operate carefully to prevent damage to the circuit board or other nearby components.

Be careful of welding fumes: The welding fumes generated during welding may be harmful to health. Work should be done in a well-ventilated area or use a soldering station with a fume exhaust function.

By following these steps, you can ensure that the desoldering work goes smoothly. The above is my personal sharing and insights on desoldering.