Water soluble solder paste is a kind of flux widely used in electronic soldering process, which can improve the wettability of solder, prevent oxidation, and clean the residue with water after soldering.

Compared with traditional solder paste, water-soluble solder paste has the following characteristics:

- Easy cleaning: water-soluble solder paste is easy to wash with water, which can simplify the subsequent cleaning process and reduce costs.

- Good thermal stability: water-soluble solder paste can be stored for a long time in a high-temperature environment, will not occur curing or delamination.

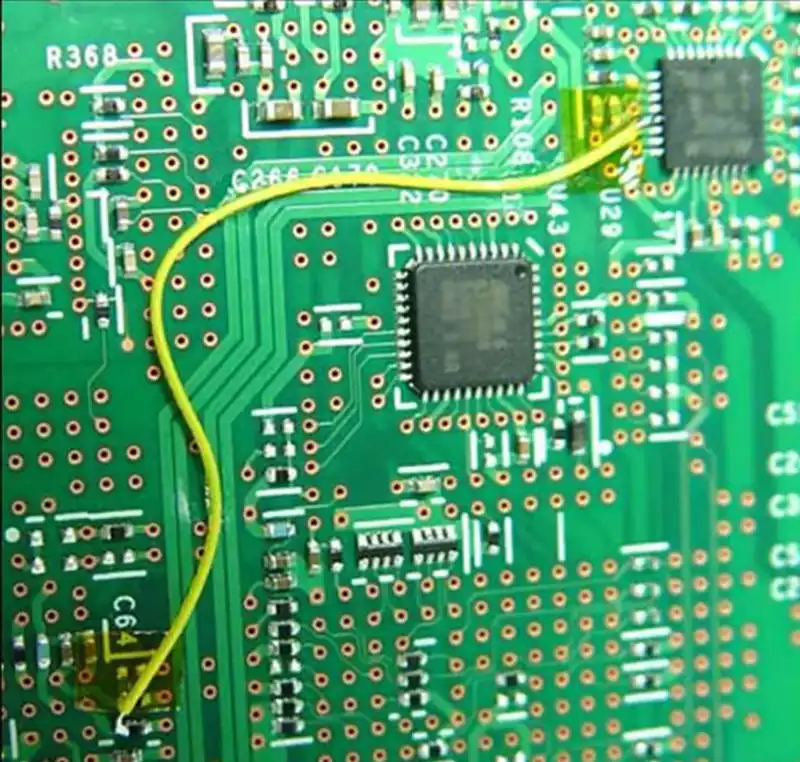

- Excellent soldering performance: water-soluble solder paste has stable soldering performance, solder joints as long as the temperature, time and soldering iron tip is appropriate, you can get the melting point of uniformity, beautiful appearance of the solder joints.

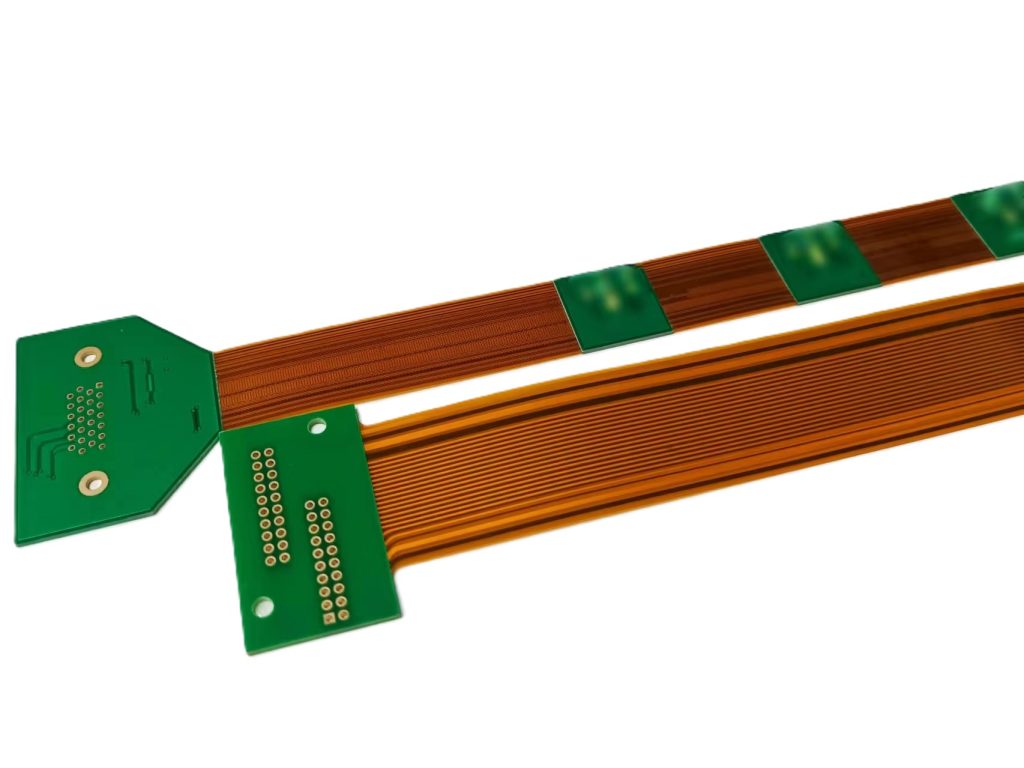

- Wide range of application: water-soluble solder paste can be used for a variety of substrates, such as FR4, ceramic substrates, organic polymer materials.

- Environmental protection: water-soluble flux does not contain harmful solvents and volatile components, friendly to the environment, in line with environmental standards.

- Low residue: water-soluble flux is easy to evaporate after welding is completed, with less residue, which will not affect the stability of the circuit.

Classification of water-soluble solder paste

According to the composition classification

Acidic water-soluble flux: The flux contains acidic ingredients such as organic acids and amine compounds, which are particularly suitable for soldering difficult-to-solder materials, such as aluminum and molybdenum and other metals, because of their strong corrosive properties and excellent cleaning effect.

Alkaline water-soluble flux: with amine salts and amino alcohols as the main constituents, its corrosiveness is relatively weak but excellent wetting performance, suitable for most welding processes, the negative impact on the welding material is small.

Classification according to function

Active flux: This type of flux contains active substances, which can effectively remove oxides and enhance the wettability of the metal surface, thereby enhancing the bond between the solder and the solder paste.

Lead-free flux: In order to meet the requirements of environmental protection, specially developed lead-free water-soluble flux, avoiding the environmental and health hazards that may be caused by traditional lead-containing fluxes.

Classification according to application areas

Water-soluble flux for SMT: Fluxes designed specifically for surface mount technology (SMT), characterized by high cleanliness and fineness of the solder joints, without affecting the adhesion of electronic components and subsequent processing.

Water-soluble flux for wave soldering: especially suitable for wave soldering process, which requires the appearance of solder joints to be flat and bubble-free after soldering to ensure the solidity of the solder joints and good electrical conductivity.

The use of water washing process need to consider the following factors

(a) in order to ensure the quality of cleaning, the use of pure water quality must meet certain requirements;

(b) the use of appropriate temperature, pressure and time for cleaning, otherwise it will lead to incomplete removal of residues or damage to components;

(c) water-soluble flux should be stored in a dry, cool environment to avoid moisture absorption and deterioration, to ensure its performance stability.

In short, the water-soluble flux superior fluxing performance, easy to clean features and friendly to the environment, making it a reliable choice for electronic soldering, promoting the progress and development of electronic manufacturing technology. When used, the corresponding operating procedures should be followed to ensure welding quality and work safety.

Precautions for the use of water-soluble flux

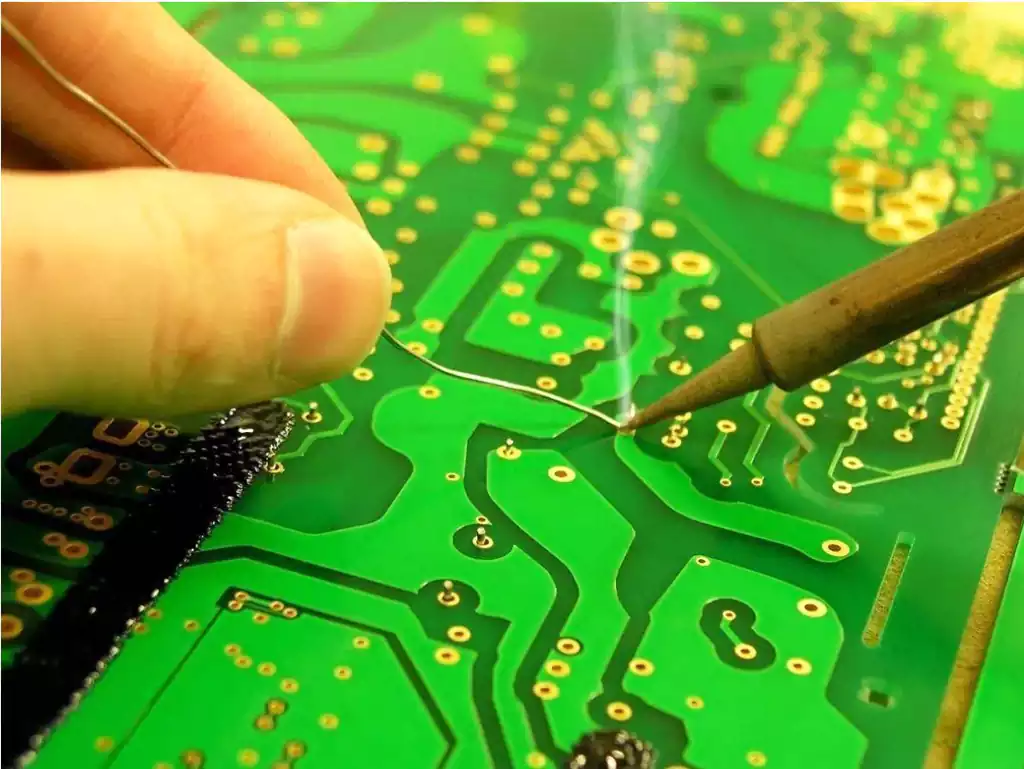

- In the process of use, you need to often add special diluents to adjust the concentration of active agent to ensure good welding results.

- Does not contain rosin resin, so tin-lead alloy solder anti-oxidation is very necessary.

- Cleaning with high purity ionized water cleaning, temperature 45 ~ 60 ℃ is appropriate, sometimes up to 70 ~ 80 ℃ ℃.

- The soldered PCB by the water after cleaning to use ion purity meter to determine the amount of ionic residue, in order to assess the effect of water cleaning.

- Requirements for welding after welding within 2h for cleaning.

Water-soluble solder paste with its unique flux performance, easy to clean features and environmental friendliness, in the field of electronic welding has occupied a pivotal position. It not only improves the wettability of the solder and prevents oxidation, but also makes it easy to clean the residue with water after soldering, greatly simplifying the subsequent cleaning process. Its application not only promotes the progress and development of electronic manufacturing technology, but also provides us with a more environmentally friendly and efficient soldering solutions.