The core relationship between lead-free soldering and FR4 boards lies in the challenge posed by the elevated soldering temperature to the thermal properties of the substrate. Compared to traditional leaded soldering, the temperature characteristics of lead-free soldering directly exceed the performance limits of conventional FR4, compelling upgrades in the thermal stability and mechanical strength of FR4 boards. This requirement is not arbitrarily imposed but dictated by the physical properties of lead-free solder and the fundamental demands of the soldering process.

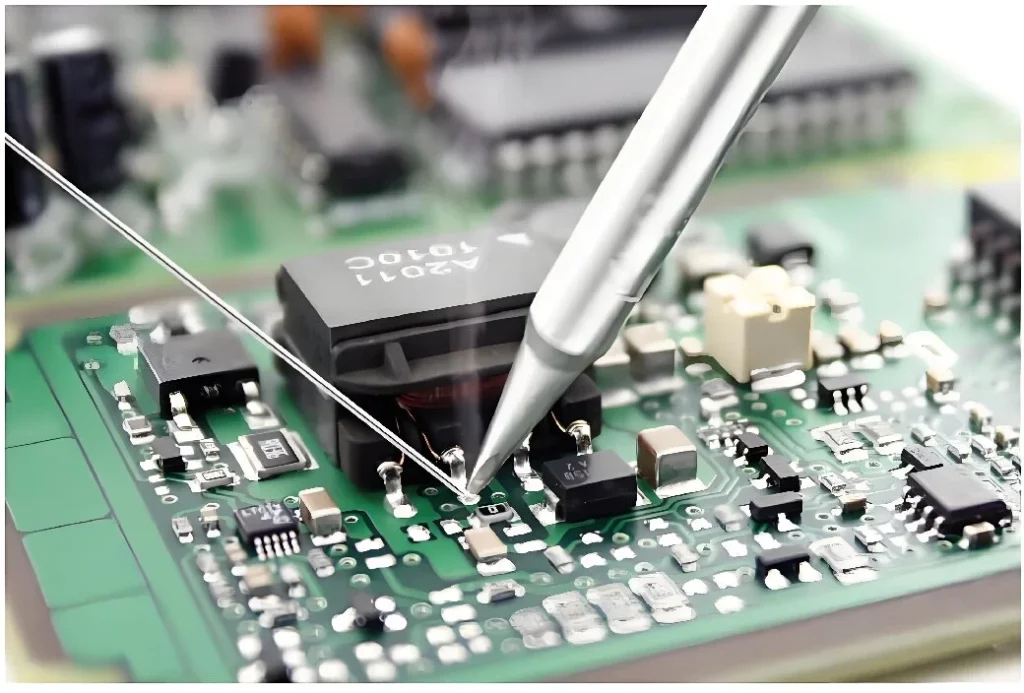

The predominant choice for lead-free solder is silver-copper-tin (SAC) alloy, possessing a melting point of 217°C – substantially higher than the 183°C of conventional tin-lead solder. To ensure complete solder melting, pad wetting, and reliable joint formation, lead-free soldering requires actual peak temperatures of 250–270°C, with complex PCBs reaching up to 280°C. More critically, lead-free soldering requires extended high-temperature dwell times—increasing from 30–60 seconds for leaded soldering to 60–120 seconds, with some high-precision processes reaching 150 seconds. This dual characteristic of ‘high peak temperature + prolonged dwell time’ subjects FR4 boards to prolonged exposure to extreme thermal conditions. Conventional FR4 has a glass transition temperature (Tg) of merely 130–140°C, causing it to rapidly enter a highly elastic state under lead-free soldering conditions, resulting in severe performance degradation.

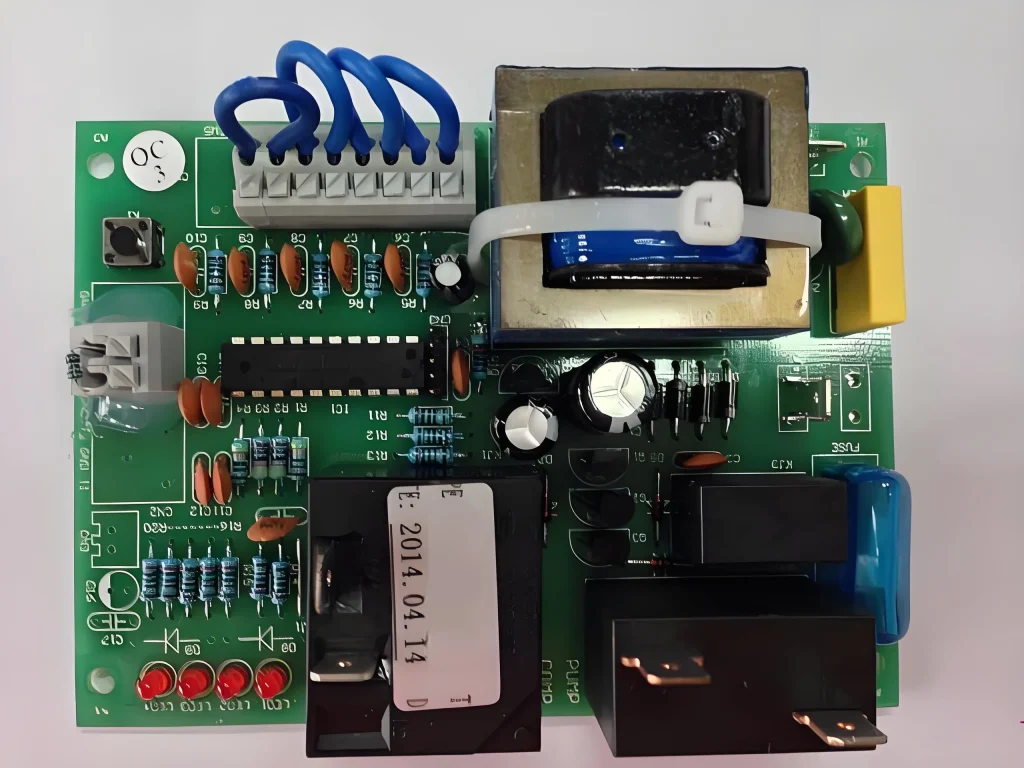

Moreover, lead-free solder exhibits heightened chemical reactivity in its molten state, demonstrating greater corrosive effects on the epoxy resin and solder mask layers of FR4 boards. Furthermore, post-lead-free soldering, PCBs deployed in end-use applications such as industrial control systems or automotive electronics must endure prolonged exposure to elevated temperatures, further accelerating the degradation of FR4 performance. Consequently, FR4 materials compatible with lead-free soldering must exhibit superior thermal stability, mechanical strength, and chemical resistance.

Core Specifications for FR4 Boards Suitable for Lead-Free Soldering

1.Glass Transition Temperature (Tg):

Tg represents the critical temperature at which FR4 transitions from a rigid glassy state to a flexible, highly elastic state, serving as the primary indicator for lead-free solder compatibility. Conventional FR4 exhibits a Tg of merely 130–140°C. Under lead-free soldering temperatures of 250–270°C, it rapidly loses rigidity, leading to delamination, bubbling, and other defects. FR4 board suitable for lead-free soldering requires a Tg exceeding 170°C. For high-temperature lead-free soldering applications (peak temperatures of 270–280°C), substrates with Tg ≥ 180°C must be selected. Complex multilayer boards, automotive electronics, and other high-end applications necessitate products with Tg ≥ 200°C.

High-Tg FR4 achieves enhanced molecular chain cross-linking density through modified epoxy resins (e.g., phenolic epoxy, biphenyl epoxy), enabling rigidity retention at elevated temperatures while reducing thermal deformation and delamination risks. Test data indicates that FR4 with Tg ≥ 170°C exhibits no significant delamination after 90 seconds at 260°C, whereas conventional FR4 shows signs of delamination within 30 seconds under identical conditions.

2.Solder Resistance (T260):

Solder resistance (T260) denotes the duration FR4 board maintains stable properties in molten solder at 260°C, serving as a direct indicator of suitability for lead-free soldering processes. Given typical lead-free soldering dwell times of 60–120 seconds, compatible FR4 must achieve T260 ≥ 60 seconds, with complex applications requiring ≥120 seconds.

FR4 with poor solder resistance may exhibit issues such as solder mask blistering, substrate delamination, or even copper foil detachment during lead-free soldering. High-quality FR4 optimised for lead-free soldering achieves solder resistance exceeding 120 seconds through refined epoxy resin formulations and lamination processes, readily withstanding both standard and complex lead-free soldering challenges.

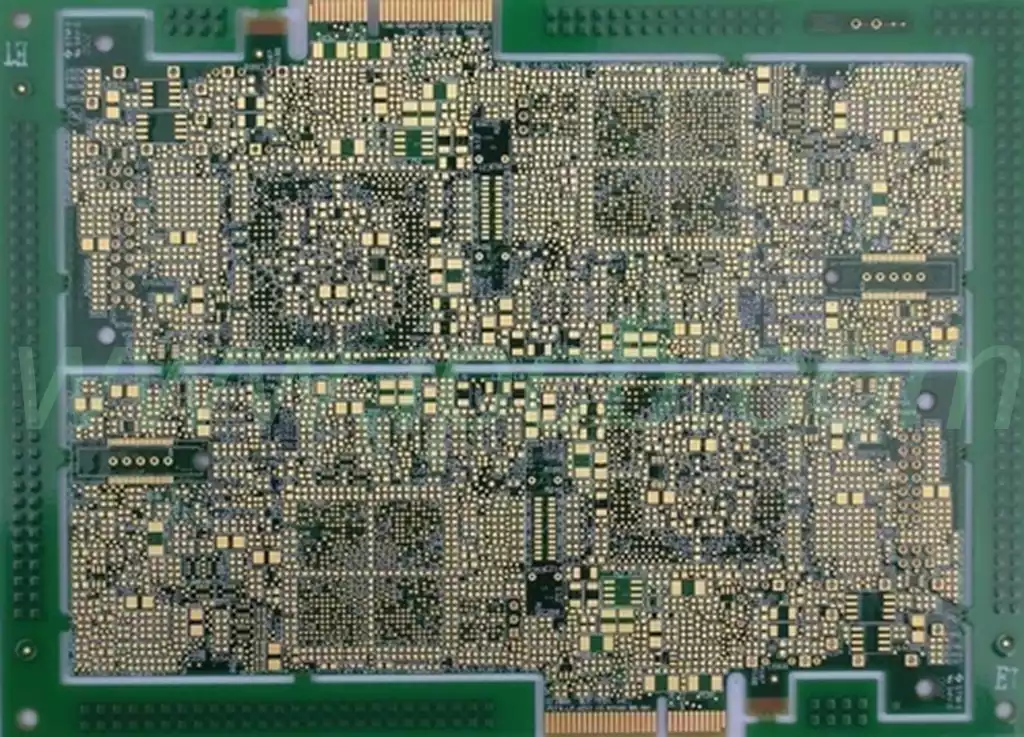

3.Coefficient of Thermal Expansion (CTE):

The Coefficient of Thermal Expansion (CTE) determines the degree of deformation in FR4 laminates during temperature fluctuations. The high temperatures of lead-free soldering cause thermal expansion and contraction in FR4 board. Excessively high CTE generates significant internal stresses, leading to PCB warping and deformation that compromises component assembly precision and solder joint reliability.

FR4 with a low CTE better matches the thermal expansion characteristics of copper foil, reducing interface stresses caused by differing thermal expansion during soldering and preventing solder joint cracking. In multilayer PCBs, low CTE is particularly crucial for effectively preventing interlayer delamination and trace fractures.

4.Chemical Stability:

FR4 materials compatible with lead-free soldering must exhibit outstanding chemical stability to withstand the corrosive effects of molten lead-free solder at elevated temperatures. Components such as tin and silver in lead-free soldering possess high chemical reactivity at high temperatures, readily reacting with the epoxy resin in conventional FR4. This reaction can cause substrate dissolution and lead to ageing and cracking of the solder mask.

Premium FR4 board achieves enhanced chemical stability through specialised solder-resistant epoxy resins and solder mask inks. This ensures stable performance under high-temperature lead-free solder conditions without chemical reactions, while preventing solder mask degradation and peeling, thereby safeguarding PCB trace integrity.

In actual production, the compatibility of lead-free soldering with FR4 frequently encounters multiple issues. These problems often stem from inappropriate board selection or mismatched process parameters, directly impacting product quality and production efficiency:

1.PCB delamination and bubbling

Causes: The selected FR4 material possesses an excessively low glass transition temperature (Tg). Under the elevated temperatures of lead-free soldering, the epoxy resin decomposes, releasing small-molecule gases. Concurrently, the interfacial bonding strength between the epoxy resin and glass fibre cloth diminishes, leading to interlaminar separation and bubbling. Additionally, excessive moisture content within the FR4 substrate can cause water evaporation at high temperatures, further inducing bubbling.

Solutions: Select high-temperature-resistant FR4 boards with Tg ≥ 170°C, ensuring solder resistance ≥ 60 seconds. Pre-bake PCBs prior to soldering (120°C, 2–4 hours) to remove internal moisture. Optimise the lead-free soldering profile by appropriately reducing peak temperature (not below 250°C) and shortening dwell time at high temperatures (not below 60 seconds).

2.Solder Resistance (T260):

Solder resistance (T260) denotes the duration FR4 maintains stable properties in molten solder at 260°C, serving as a direct indicator of suitability for lead-free soldering processes. Given typical lead-free soldering dwell times of 60–120 seconds, comSolutions: Select high-temperature-resistant FR4 boards with low CTE (Coefficient of Thermal Expansion), controlling high-temperature deformation to ≤0.2%; optimise PCB layout to ensure symmetrical centre of gravity and uniform component distribution; incorporate PCB stiffeners and heat-dissipating copper foil to enhance mechanical strength and thermal efficiency.

3.Solder mask delamination and ageing

Causes: FR4 solder mask exhibits poor temperature resistance, unable to withstand lead-free soldering temperatures; insufficient adhesion between solder mask and substrate causes high-temperature separation; chemical corrosion from lead-free solder leads to solder mask ageing and cracking.

Solutions: Select high-temperature-resistant FR4 boards using specialised solder-resistant solder mask inks; Ensure solder mask peel strength ≥ 1.5 N/mm; Optimise soldering processes to avoid excessive temperatures and prolonged dwell times.

4.Poor solder joint quality, cold solder joints

Causes: Low-molecular-weight substances released from FR4 boards contaminate pads during high temperatures, impairing solder wetting; PCB warping causes component lead misalignment with pads; Poor chemical compatibility between FR4 and solder compromises joint strength.

Solutions: Select high-heat-resistant FR4 with excellent thermal stability and no harmful emissions; clean pads prior to soldering to remove contaminants; ensure PCB warpage ≤0.2% to maintain component placement accuracy; choose FR4 boards compatible with lead-free solder.

Lead-free soldering process parameters and end-use operating environments vary across different applications, necessitating distinct performance requirements for FR4 materials. Selecting FR4 precisely tailored to specific application demands ensures quality assurance while optimising costs:

1.Consumer electronics applications (smartphones, laptops)

Characteristics: Lead-free soldering peak temperature 250–260°C, high-temperature dwell time 60–90 seconds; PCBs typically feature multi-layer high-density designs demanding high dimensional stability; end-use operating temperatures range from low (-10°C to 60°C) to moderate, with medium cost sensitivity.

Selection recommendation: Opt for high-heat-resistance FR4 laminates with Tg ≥ 170°C, T260 ≥ 60 seconds, and low CTE. Such materials accommodate consumer electronics’ lead-free soldering processes, ensure PCB dimensional stability, control costs, and meet mass production requirements.

2.Industrial Control Applications (Inverters, Servo Drives)

Characteristics: Lead-free soldering peak temperature 270-280°C, high-temperature dwell 90-120 seconds; high terminal operating temperature range (-20°C to 120°C) requiring long-term high-temperature endurance; stringent demands on insulation properties and mechanical strength.

Selection Recommendations: Opt for high-heat-resistant FR4 laminates with Tg ≥ 180°C, T260 ≥ 120 seconds, low loss, and high insulation performance. Such laminates withstand the stresses of high-temperature lead-free soldering while meeting industrial control applications’ prolonged high-temperature operation requirements, ensuring stable equipment performance.

3.Automotive electronics applications (new energy vehicle inverters, OBC)

Characteristics: Lead-free soldering peak temperatures of 270–280°C with dwell times of 100–150 seconds; harsh terminal operating environments requiring endurance against multiple stresses including high temperatures (-40°C to 150°C), vibration, and humidity; extremely high reliability demands necessitating compliance with stringent automotive industry standards.

Selection Recommendations: Opt for premium high-heat-resistant FR4 laminates with Tg ≥ 200°C, T260 ≥ 120 seconds, low CTE, radiation resistance, and chemical corrosion resistance. These laminates undergo rigorous environmental testing to align with automotive electronics’ lead-free soldering processes and end-use conditions, safeguarding vehicle operational safety.

4.Aerospace and Medical Equipment Applications

Characteristics: Complex lead-free soldering processes involving peak temperatures exceeding 280°C with dwell times of 120–180 seconds; extreme end-use environments (e.g., high temperatures, radiation, vacuum) demanding military-grade reliability standards; stringent requirements for substrate consistency and stability.

Selection Recommendations: Opt for premium, high-heat-resistant FR4 laminates certified to military standards, featuring Tg ≥ 200°C and T260 ≥ 180 seconds. Such laminates deliver exceptional thermal stability and environmental adaptability, accommodating extreme lead-free soldering processes and end-use scenarios to ensure stable equipment operation under harsh conditions.

The compatibility between lead-free soldering and FR4 is not merely a simple pairing of ‘process and material,’ but rather a precise alignment based on thermal characteristics, performance requirements, and application-specific variations. The high-temperature nature of lead-free soldering necessitates that FR4 boards possess outstanding thermal stability and mechanical strength. Meanwhile, differing application demands require FR4 selection to balance both quality and cost considerations.soldering achieves solder resistance exceeding 120 seconds through refined epoxy resin formulations and lamination processes, readily withstanding both standard and complex lead-free soldering challenges.

3.Coefficient of Thermal Expansion (CTE):

The Coefficient of Thermal Expansion (CTE) determines the degree of deformation in FR4 laminates during temperature fluctuations. The high temperatures of lead-free soldering cause thermal expansion and contraction in FR4. Excessively high CTE generates significant internal stresses, leading to PCB warping and deformation that compromises component assembly precision and solder joint reliability.

FR4 with a low CTE better matches the thermal expansion characteristics of copper foil, reducing interface stresses caused by differing thermal expansion during soldering and preventing solder joint cracking. In multilayer PCBs, low CTE is particularly crucial for effectively preventing interlayer delamination and trace fractures.

4.Chemical Stability:

FR4 materials compatible with lead-free soldering must exhibit outstanding chemical stability to withstand the corrosive effects of molten lead-free solder at elevated temperatures. Components such as tin and silver in lead-free solder possess high chemical reactivity at high temperatures, readily reacting with the epoxy resin in conventional FR4 board. This reaction can cause substrate dissolution and lead to ageing and cracking of the solder mask.

Premium FR4 board achieves enhanced chemical stability through specialised solder-resistant epoxy resins and solder mask inks. This ensures stable performance under high-temperature lead-free solder conditions without chemical reactions, while preventing solder mask degradation and peeling, thereby safeguarding PCB trace integrity.

In practical production, matching lead-free soldering with FR4 board frequently presents multiple challenges. These issues often stem from inappropriate board selection or mismatched process parameters, directly impacting product quality and manufacturing efficiency. Only by clarifying the causes of these difficulties and their solutions can one…