The MSL (Moisture Sensitive Level) standard is a classification system used by the electronics industry to assess the sensitivity of components to moisture, which classifies components into eight different levels based on their sensitivity to moisture. These levels reflect the amount of time a component can be safely stored under specific temperature and humidity conditions without its performance or reliability being affected by moisture absorption.

MSL 1: This is the lowest sensitivity level and indicates that components can be stored indefinitely at no more than 30°C and 85% relative humidity without regard to shop life limitations.

MSL 2: Components can be stored for up to one year at no more than 30°C and 60% relative humidity without any impact on their performance.

MSL 2a: Similar to MSL 2, but the shop life of the component is reduced to four weeks.

MSL 3: The shop life of the component is further reduced to 168 hours, or one week.

MSL 4: The workshop life of the component is 72 hours, i.e. three days.

MSL 5: The workshop life of the component is 48 hours, i.e. two days.

MSL 5a: The workshop life of the component is 24 hours, i.e. one day.

MSL 6: Components have a shop life of 12 hours. For components of this rating, they must be baked before reflow and reflowed within the time specified on the moisture sensitivity label.

Importance of Moisture Sensitivity Rating for Diodes

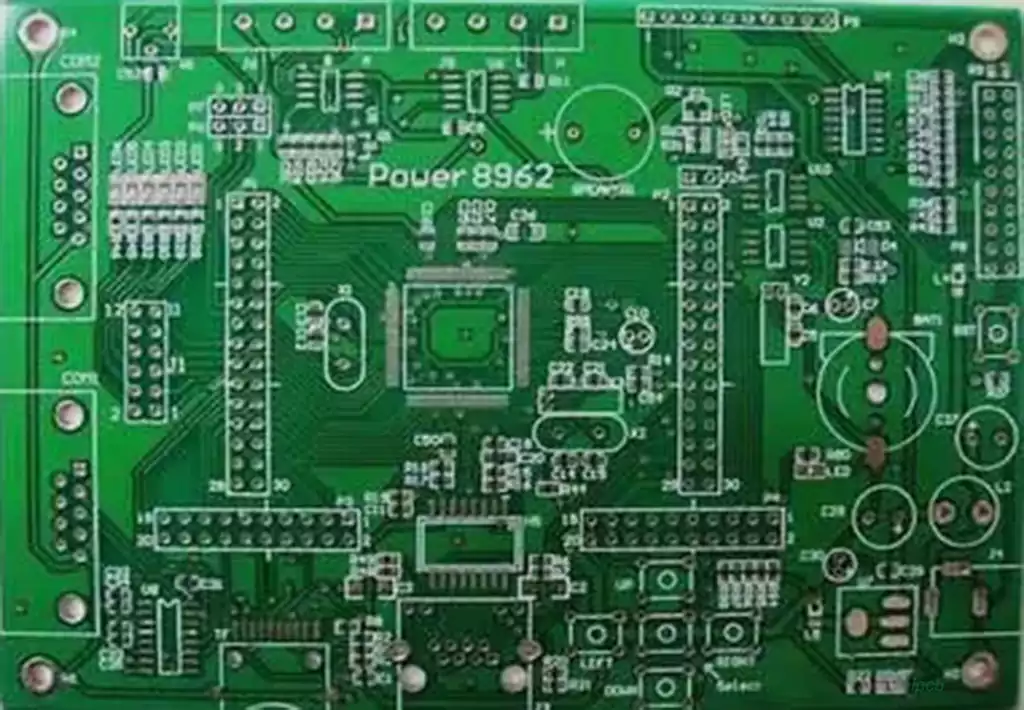

In the semiconductor industry, moisture sensitivity rating is an important indicator of how sensitive a component is to humidity. For a basic electronic component such as a diode, the moisture sensitivity level directly affects its performance and stability in different humidity environments.

The Moisture Sensitivity Level (MSL) of a semiconductor package is an important indicator of the sensitivity and reliability of electronic components under humidity conditions. The following are the factors that determine the Moisture Sensitivity Level of a semiconductor package:

Package Material:

Different packaging materials have different ability to absorb and release moisture, which directly affects the component’s Moisture Sensitivity Level.

Encapsulation process:

The control of temperature, pressure and other parameters in the encapsulation process, as well as the hermeticity after encapsulation, will affect the moisture sensitivity level of the component.

Environmental conditions:

Components in the production, storage, transport and use of the process of environmental temperature and relative humidity, is an important factor in determining its moisture sensitivity rating

Exposure time:

The longer a component is exposed to high humidity, the higher the degree of moisture absorption and the moisture sensitivity rating may increase accordingly.

In order to improve the moisture sensitivity rating of diodes, semiconductor manufacturers take a series of measures, including improving packaging materials, optimising production processes and enhancing quality testing. These measures aim to reduce moisture penetration inside and outside the components, thereby improving their stability and durability in high humidity environments.

When selecting semiconductor diodes, users should determine the required moisture sensitivity level according to specific application scenarios. For example, devices used in humid or rainy environments may require diodes with higher moisture sensitivity ratings to ensure stable long-term operation. Devices used in dry or indoor environments, on the other hand, may choose components with lower moisture sensitivity ratings.

With the development of electronic devices to a higher degree of integration, smaller size and a wider range of applications, the impact of humidity on the performance of the components will be more and more prominent, and the importance of the MSL level will increase day by day. The semiconductor industry will continue to plough into the development of packaging materials and process innovation, and strive to break through the limits of humidity resistance, to create a stronger ‘humidity defence’ for the components.