Automated optical inspection (automatedopticalinspection,AOI) technology, also known as machine vision inspection (machinevisioninspection,MVI test) technology or automatedvisualinspection (automatedvisualinspection,AVI) technology. In some industries, such as flat panel display, semiconductor, solar and other manufacturing industries, the term AOI is more popular and known. However, there are still subtle differences between AOI and MVI/AVI in terms of concept and function.

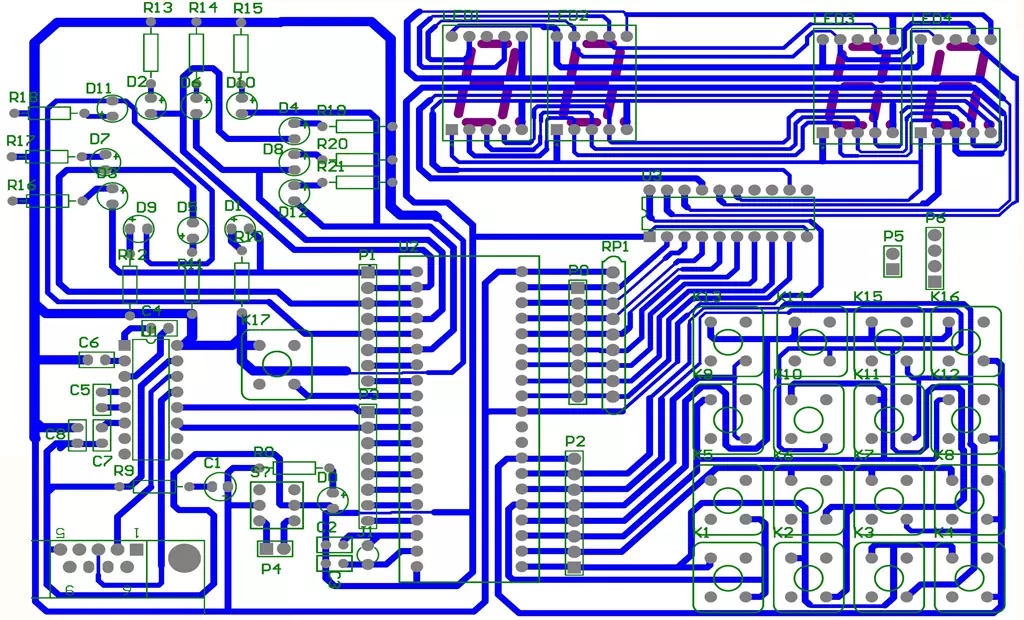

In a narrow sense, MVI test is an emerging science and technology that integrates image sensing technology, data processing technology, and motion control technology to perform tasks such as measuring, detecting, recognizing, and guiding in the industrial production process.The basic principle of MVI can be represented in Figure 1, which adopts an optical imaging method (such as a camera, or a complex optical imaging system) to mimic the visual imaging function of the human eye, and replaces the human brain with a computer processing system to perform the visual imaging function. Computer processing system instead of the human brain to perform data processing, and finally the results are fed back to the actuator (e.g., robot) instead of the human hand to complete a variety of prescribed tasks.

Broadly speaking, MVI is a kind of technology that simulates and expands the functions of human eyes, brain and hands, and its definition may have subtle differences in different application fields, but all of them can’t leave the two fundamental methods and technologies, i.e., obtaining the required information from images and then feeding it back to the automation actuators to complete specific tasks. It can be said that based on any image sensing methods (such as visible light imaging, infrared imaging, X-ray imaging, ultrasound imaging, etc.) of automated inspection technology can be considered MVI or AVI. when the use of optical imaging methods, MVI in fact becomes AOI. so AOI can be considered a special case of MVI.

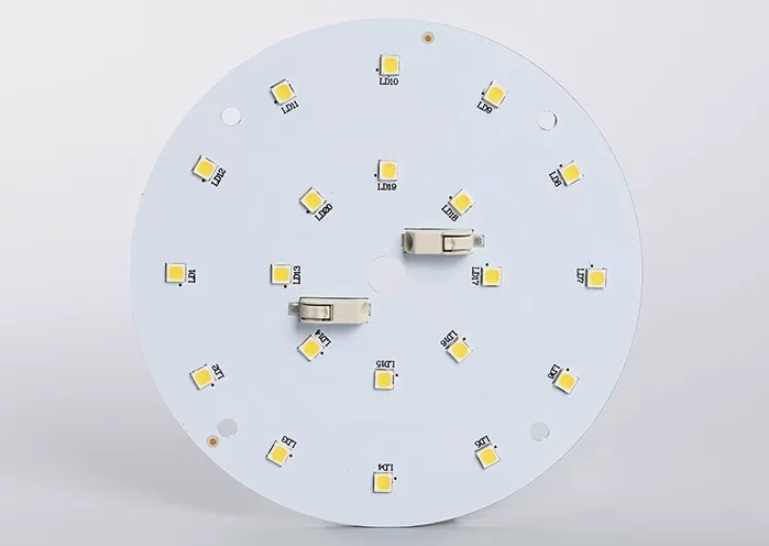

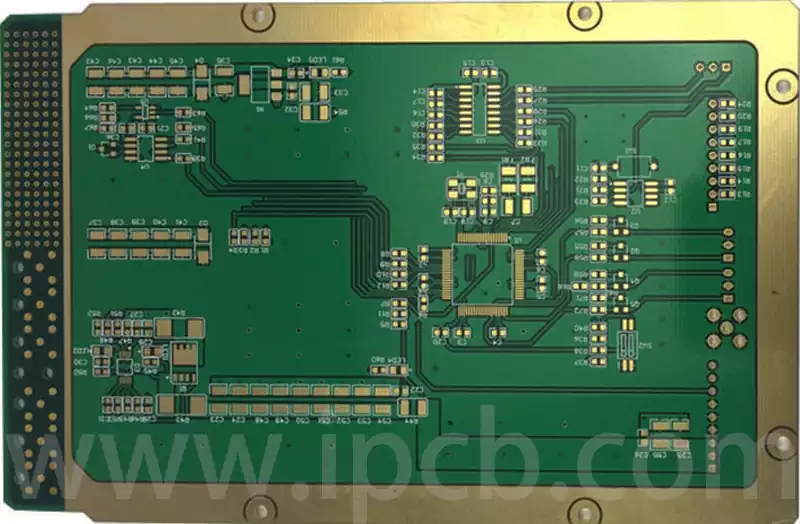

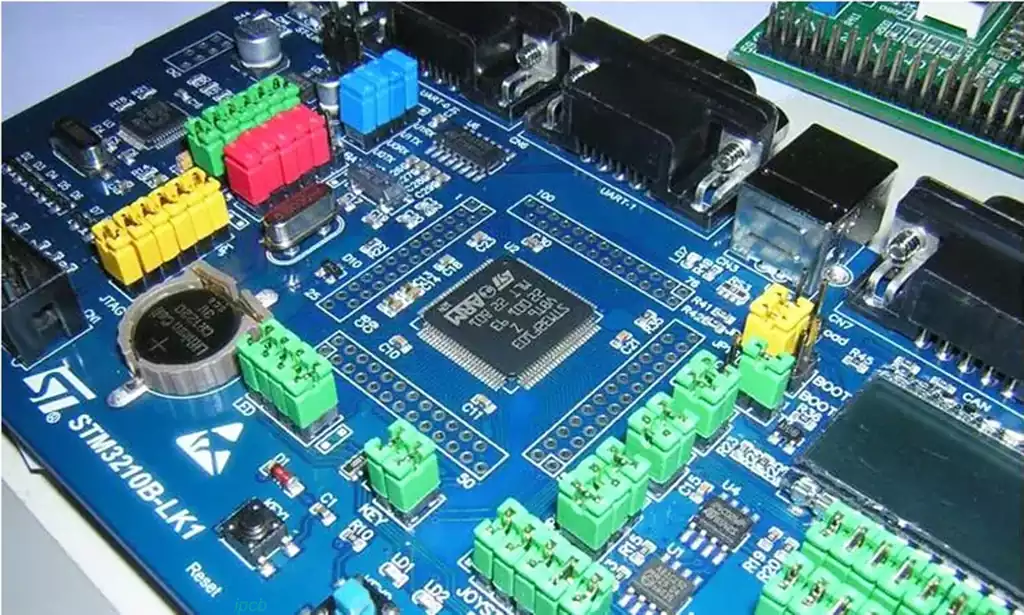

MVI utilizes the rapid development of CMOS and CCD cameras, image processing and pattern recognition technologies, digital image sensors, and embedded technologies (DSP, FPGA, ARM, etc.) to promote the progress of machine vision inspection technology. In short, MVI is a new technology that carries out various measurements and judgments through machines instead of human eyes, which integrates image processing technology (SRC), photoelectric detection technology (MSM) and computer application technology (Enterterms). The introduction of MVI into industrial PCB inspection is because it has significant advantages such as fast, non-contact, good flexibility, etc., which plays an important role in the inspection of electronic manufacturing industry. At the same time, machine vision can also realize the automatic defect detection of PCB light boards, avoiding huge losses in the production process, which has a highly realistic economic value for the development of the electronics field.

In the initial stages of PCB manufacturing, MVI testing is a good starting point, especially for relatively simple PCBs. workers view the boards with the naked eye or with the aid of magnification tools, comparing them to the design documentation to ensure that all specifications are met and to look for possible defects. This approach quickly and effectively captures common problems that may arise during the manufacturing process.

MVI testing also plays an important role in the assembly of electronic components. It checks the quality of component placement, insertion and soldering to ensure that each component is connected and fixed as intended.

MVI testing is also essential for PCB products that require a high degree of precision, such as communication equipment, medical equipment, aerospace equipment, etc. In these areas, where any small defect can lead to serious consequences, rigorous visual inspection is required to ensure product quality.

MVI test is widely used in all stages of PCB manufacturing and electronic component assembly, and is one of the most important means of ensuring product quality and reliability. However, it should be noted that although MVI testing has advantages such as intuitiveness and immediacy, for some tiny defects or complex defect patterns, it may be necessary to combine other advanced inspection equipment and techniques for more accurate detection and identification.