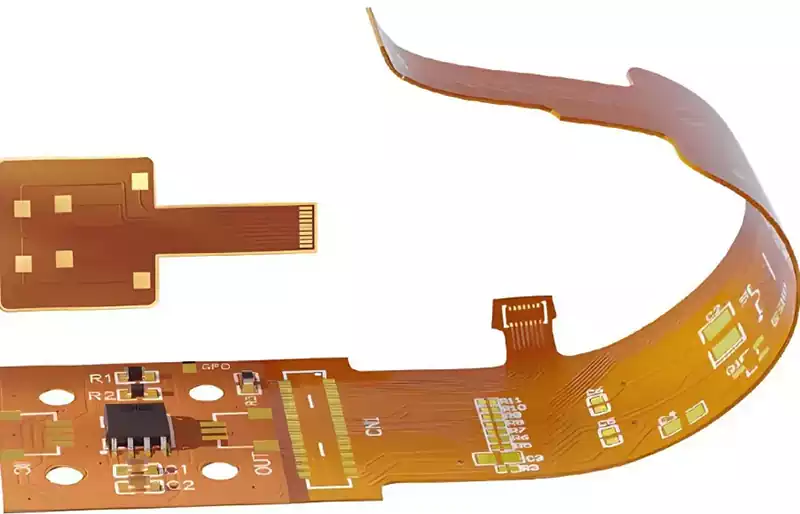

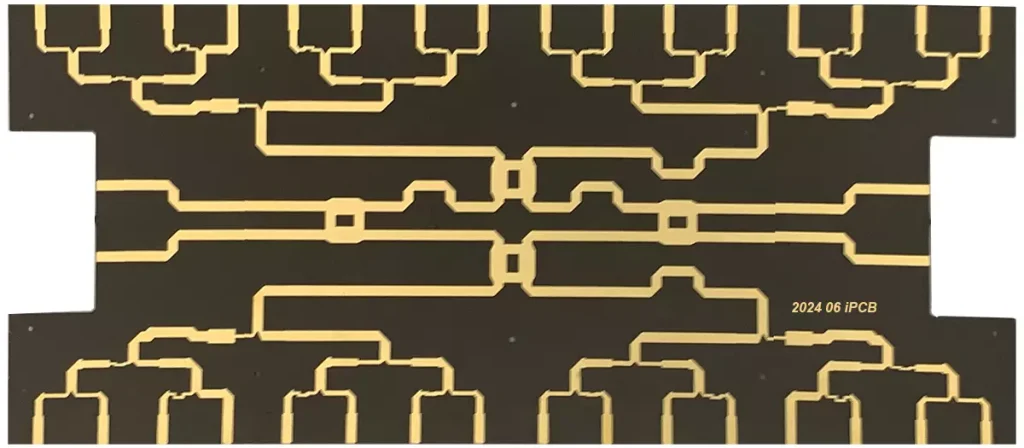

In this era of rapid advancement in high-speed communications, RF microwave technology, and 5G applications, the selection of high-frequency hybrid-material boards has become a critical issue engineers must confront. The hybrid-material process combining RO4350B with FR4, leveraging its distinctive performance advantages, demonstrates exceptional application value across numerous scenarios.

RO4350B is a commonly employed microwave circuit substrate, primarily composed of polyimide material, offering excellent electrical properties and mechanical strength. Its relative permittivity (Er) is approximately 3.48, with a dielectric loss tangent (Df) typically ranging between 0.0030 and 0.0035, meeting the demands of high-frequency circuits.

The suitable frequency range for RO4350B typically extends to 40 GHz and beyond, facilitating its widespread adoption in high-frequency microwave and radio-frequency applications. Particularly in circuits handling high-frequency signal transmission and processing—such as radio-frequency amplifiers, antennas, power dividers, and filters—RO4350B demonstrates commendable high-frequency performance and thermal stability.

Furthermore, the RO4350B maintains stable performance under varying ambient temperatures, making it suitable for diverse industrial and commercial applications. Its low dielectric loss effectively minimises signal attenuation, thereby enhancing the overall efficiency of microwave circuits.

What key factors should be considered when selecting FR4 laminates?

Material Tg value: The performance of FR4 primarily depends on the Tg value within the epoxy resin system, categorised into low, medium, and high grades. A higher Tg value correlates with greater board reliability. When selecting laminates, comprehensively evaluate loss levels and supplier stability based on specific application requirements, such as the number of circuit board layers and prevailing environmental conditions.

Operating Frequency Characteristics: Rogers RO4350B material exhibits distinct performance characteristics compared to FR4 across different frequencies. FR4 maintains a dielectric constant within the 4.2–4.7 range, with a loss factor of 0.015 or lower; whereas RO4350B exhibits a dielectric constant within 3.48±0.05 and a loss tangent of 0.0037 at 10GHz. For high-frequency applications, RO4350B offers superior hybrid-pressure performance.

Mechanical Strength: FR4 laminates possess high strength and stability, capable of withstanding mechanical stress and high-temperature environments. Its excellent heat resistance complies with the UL94 V-0 flame retardant standard, ensuring the board maintains stability in high-temperature environments or during fire incidents.

Cost and Efficiency Considerations: FR4 sheets offer relatively low production costs, making them highly suitable for mass manufacturing and widely adopted across various electronic devices. Their outstanding stability and durability enable them to serve as virtually maintenance-free permanent materials in numerous applications.

Environmental Adaptability: FR4 sheets exhibit outstanding dimensional stability and chemical resistance, maintaining performance across diverse environments. Their excellent flame-retardant properties generate minimal harmful gases during combustion, meeting environmental requirements.

Electrical Performance: FR4 sheets possess superior insulation properties and stable electrical characteristics, featuring low dielectric constants and dielectric loss factors, making them highly suitable for high-frequency applications. These characteristics ensure stable and high-quality signal transmission within electronic devices.

Scope of Application: FR4 sheets are primarily used in manufacturing multilayer printed circuit boards, serving diverse sectors including consumer electronics, communication equipment, automotive electronics, and aerospace. Their superior mechanical and electrical properties enable more reliable and efficient operation of electronic products.

Challenges in RO4350B and FR4 Hybrid Laminate Processes:

Thermal Coefficient of Expansion (CTE) Mismatch

The CTE of RO4350B (approximately 10 ppm/°C along X/Y axes and 32 ppm/°C along Z axis) differs significantly from that of FR4 (14–17 ppm/°C along X/Y axes and 40–60 ppm/°C along Z axis). During temperature fluctuations, the differing expansion and contraction rates of these materials can induce shear stresses between layers, leading to delamination, warping, and other issues that compromise the long-term reliability of the circuit board.

Complex impedance control

RO4350B and FR4 exhibit differing dielectric constants (Dk) (RO4350B approx. 3.48, FR4 approx. 4.2–4.7), whilst the Dk of the prepreg also influences impedance. In mixed-material designs, precise calculation of each layer’s impedance is essential to ensure signal transmission continuity and stability. Minimal Dk variations may induce impedance deviations, compromising signal integrity—particularly critical in high-frequency applications (e.g., 5G, millimetre wave) demanding stringent impedance matching.

Laminating Process Parameter Optimisation Difficulties

Lamination must concurrently satisfy RO4350B and FR4 process requirements. Temperature, pressure, and time parameters demand precise control to ensure interlayer bonding strength and uniform resin filling between materials. Inappropriate parameters may result in resin voids, bubbles, or delamination, compromising the board’s electrical performance and mechanical strength.

Drilling and Plating Challenges

The differing hardness and drilling characteristics of RO4350B and FR4 necessitate adjustments to drill parameters and feed rates during drilling to prevent burrs, chipping, or drill wear. During plating, variations in surface roughness and conductivity between the materials may cause uneven plating thickness, compromising the electrical performance and reliability of the vias.

Significant Reliability Verification Challenges

Hybrid boards require reliability testing under multiple environmental conditions (e.g., temperature cycling, humidity, vibration) to validate interlayer bonding strength, impedance stability, and signal transmission performance. Due to material property variations, testing standards and methodologies require tailored design, increasing verification costs and lead times.

Balancing Cost and Yield

The higher cost of RO4350B necessitates trade-offs between performance requirements and cost control in hybrid-pressure designs. Concurrently, process complexity may reduce production yield, demanding optimised workflows and enhanced quality control to improve manufacturing efficiency and product qualification rates.

Amidst the expanding applications of high-speed communications, RF/microwave, and 5G technologies, the hybrid RO4350B and FR4 process offers unique advantages, unlocking new possibilities for high-frequency circuit design and demonstrating significant potential across diverse fields. Despite numerous challenges, ongoing technological refinement and process optimisation will undoubtedly overcome these bottlenecks, enabling this technology to shine brilliantly within the electronics sector.