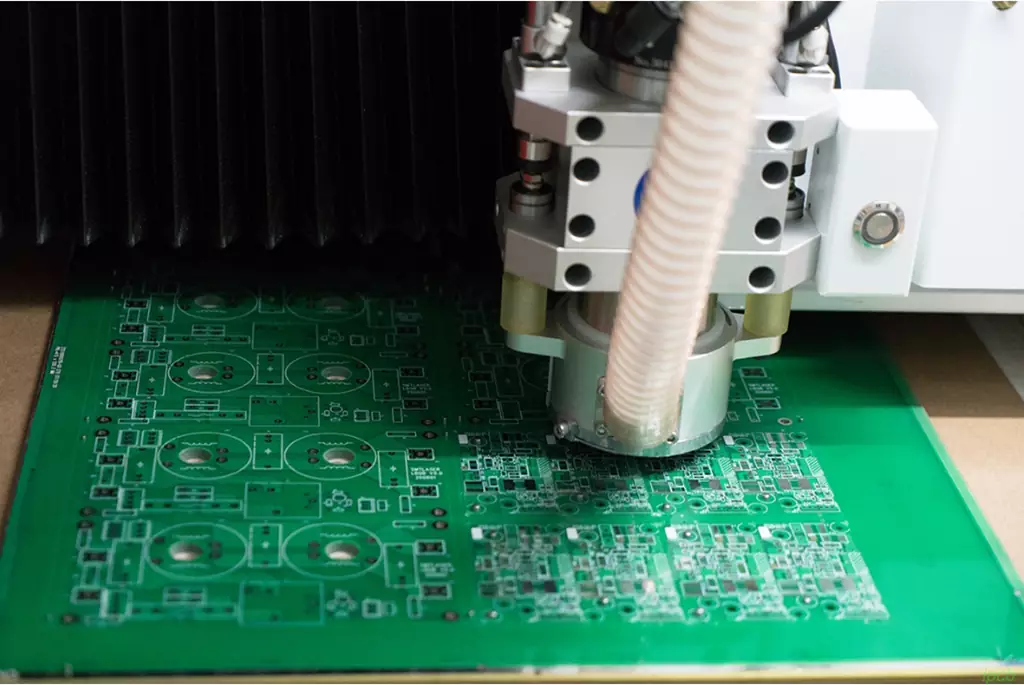

PCB CNC milling machine is an advanced point-to-point motion control system, which plays a key role in manufacturing high-precision printed circuit board through-hole. With the gradual miniaturization and refinement of electronic products, the printed circuit board conductive holes in the aperture, line width and line spacing requirements have become more stringent. Accordingly, PCB CNC system is constantly moving towards higher speed, accuracy, reliability, system integration, flexibility and intelligent direction.

Advantages of using CNC milling machine PCB processing

High precision

Precise and reliable position and aperture size control. The positional accuracy of CNC milling machine is as high as ±0.0025MM, which ensures the accuracy of parts assembly and the consistency between the drilling center and the center of the pad position on the film.

High Reliability

Strong stability. Modern CNC drilling machines are equipped with infrared detection devices and automatic needle breakage alarm systems. If the drill size does not meet the program requirements, or the depth of the drill into the plate is out of tolerance, the machine will stop working and sound an alarm until the fault is removed and continue to run.

Easy to operate

Once the drilling program is complete, the drill nozzles are arranged in the programmed order and all subsequent work can be left to the machine.

Efficient and fast

Modern high-speed drilling machines are capable of drilling more than 1,000 holes per minute, and in the absence of malfunctions, they work automatically until the program is complete. If the drill bit is excessively worn, the drilling machine will automatically replace the drill bit with a new one and continue working without human intervention.

Working Principle of PCB CNC

PCB board CNC milling machines work by relying on a CNC system to control the position and depth of the drill bit for drilling operations on circuit boards. The CNC system is able to automatically adjust the movement and stopping of the drill according to a preset program, thus realizing efficient and precise drilling operations. During the drilling process, the drill bit will continue to rotate and advance downward until the drilling is completed.

The structural composition of PCB CNC

Machine tool: The machine tool is the main part of PCB CNC milling machine, including the body, table, spindle, guideway and other components.

CNC system: CNC system is the core of PCB CNC milling machine, composed of CNC controller, servo motor, encoder and other components.

Drill: Drill is the execution part of PCB CNC milling machine, including drill clamping device, drill body, drill and other pcb components.

Cooling system: the cooling system is the auxiliary part of circuit board CNC milling machine, consisting of cooling water tank, water pump, water pipe and other parts.

PCB numerical control operation method

Startup: first turn on the power switch, wait for the machine self-test to complete, then press the start button to start the machine.

Load program: Transfer the pre-written drilling program to the CNC system through USB flash drive or network.

Adjust drill bit: Select the appropriate drill bit according to the requirements of the circuit board and use the drill bit clamping device to fix the drill bit on the spindle.

Adjust the table: Adjust the position and height of the table according to the requirements of the circuit board to ensure that it matches the position and depth of the drill bit.

Start drilling: Start the drilling program in the CNC system, the machine will automatically control the position and depth of the drill to complete the drilling operation.

PCB CNC milling machine is an indispensable and important equipment in the field of electronic manufacturing, which can efficiently and accurately complete the drilling operation and improve the production efficiency and product quality.