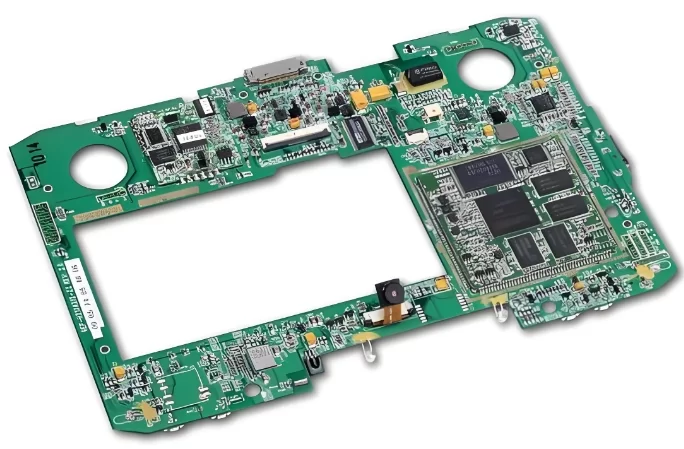

PCB corrosion is a major cause of electronic product failure. Initially the effect of corrosion is to increase the resistance of the copper traces on the board, but as the level of corrosion increases, the PCB becomes less efficient or even stops working.

Corrosion is an oxidizing process that occurs when oxygen combines with metal, producing rust and causing the metal to flake and lose its valuable chemical properties. Since PCBs are primarily made of metal and are exposed to oxygen, they are susceptible to corrosion.

Factors leading to PCB corrosion

- Electrolytes

When an electric current is applied to a conductor, an electric field is generated, which can cause electrons to flow from one terminal of the circuit to the other. The electrons leave behind ions/charged particles, which are attracted to the surface of the conductor and adhere to it causing corrosion, a process known as electrochemical migration.

This migration usually occurs in the presence of an electrolyte, the most common electrolyte being water.

- Moisture

Moisture that penetrates the metal of the PCB board is particularly susceptible to corrosion, and if uncontrolled, enters other parts of the PCB and can cause serious damage.

3.Moisture

Excessive humidity in the air can lead to oxidization of the materials used in the circuit board.

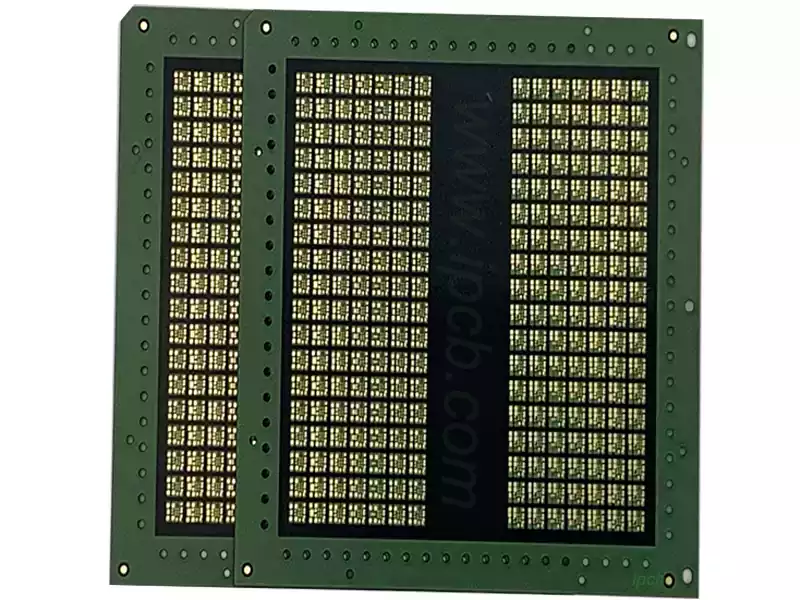

- Flux Residues

Flux residue is mainly left behind during the soldering process, usually composed of borax, chlorinated pressed and lead acetate and other chemicals, these chemicals will corrode the copper trace on the PCB, the longer the corrosion is more serious.

How to clean a circuit board of corrosion

Using compressed air

Compressed air is a fairly common tool used for electronic cleaning. You can use compressed air by releasing short pulses into the interior of the ventilation holes. This type of cleaning is recommended for routine electronics care, so to deal with corrosion you will need to open up the electronics and hit them at the source.

Using Baking Soda

Baking soda is a highly effective ingredient used to remove PCB corrosion. Not only that, but your kitchen cabinets probably already contain baking soda. Since baking soda is moderately abrasive, you can use it to scrub corrosion and residue that won’t be released by compressed air. Try using it with a gentle brush and distilled water.

Use Distilled Water

Speaking of distilled water, this product is also a great way to safely and easily remove corrosion from circuit boards. Distilled water in its purest form will not degrade or damage your electronics.

Use Household Cleaners

Any household cleaner is a great solution for PCB corrosion, but only if it is phosphate-free. Phosphates are effective in preventing corrosion, but they are a significant source of pollution in American lakes throughout the United States. However, there are so many phosphate-free cleaners that work just fine. Specialized PCB corrosion cleaners are also available on the market.

Using a Brush

A brush can be a super useful tool when you are cleaning circuit boards as it helps you get in between all the tiny components. Choosing a brush with soft bristles is crucial. Size is also important as you need to be able to reach all the smallest spaces.

Most people prefer to use toothbrushes or paint brushes. They are sturdy and gentle and most people already own at least one of them.

A lint-free microfiber cloth is also great for wiping and drying circuit boards immediately after cleaning.

To prevent circuitry from rusting

- Keep the environment dry

In order to prevent circuit boards from rusting in a humid environment for a long period of time, you can keep the environment dry by adding a drying device to the place where you use the electrical equipment. - Use a moisture-proof box

When storing circuit boards, you can use a moisture-proof box to protect them from moisture and rust.

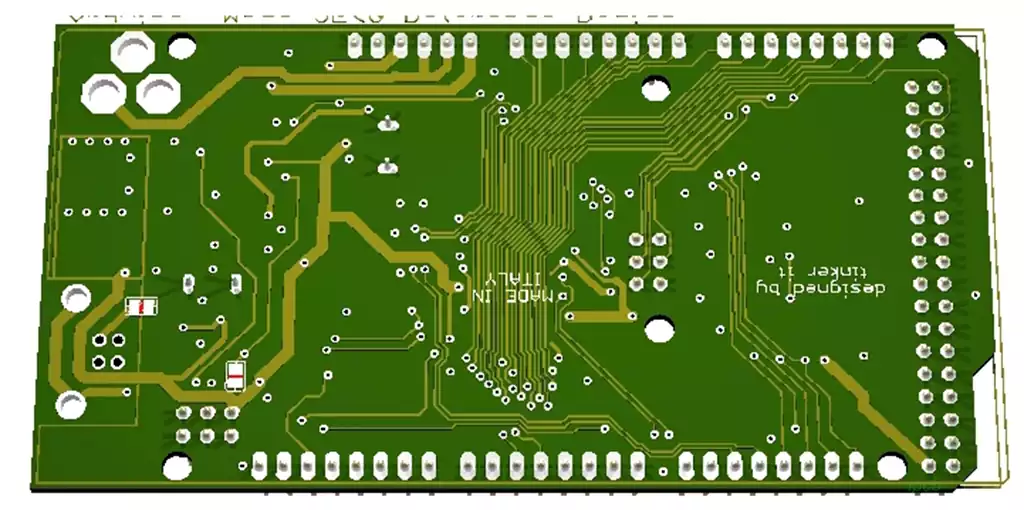

Steps to how to remove corrosion from pcb

After preparing all the necessary cleaners and tools for working on the board, you can follow the given steps to clean the corrosion from the board:

- First turn on the given electrical device or appliance and remote the PCB by disconnecting all connections and power supply.

- Record the layout and configuration of the PCB, it is important to memorize every detail because after cleaning you will need to reassemble the PCB.

- When using the correct tool, it is important to check the manual and use the tool correctly.

- After removing the PCB, use a cleaning solution such as isopropyl alcohol or baking soda solution.

5.Now, use a soft brush to apply it to the circuit board and keep applying it until the rust and dust soften.

6.Then, you can use a brush to remove the dirt and further use distilled water to remove the remaining dust and corrosion.

7.If there is still hard corrosion on the board, you can further apply more isopropyl alcohol as it is a stronger reagent.

8.Finally, clean and dry the board with a microfiber carpet using an air dryer, then install it back into the electrical unit to remove all corrosion.

While PCB corrosion is a common cause of electronics failure, by taking the right cleaning and preventative measures, we can effectively remove corrosion and extend the life of the board. In the cleaning process, be sure to pay attention to the use of appropriate tools and cleaning agents, and follow the correct steps to avoid further damage to the circuit board. At the same time, keeping the storage and use of electronic equipment in a dry environment, the use of moisture-proof box and other protective measures, is also the key to preventing corrosion.