Printed Circuit Boards (PCBs) are the backbone of modern electronic devices. From smartphones to spacecraft, these complex yet elegant systems provide the electrical connectivity that enables electronic devices to function. But how did PCBs come to be? Understanding PCB origin and evolution offers insight into one of the most pivotal technologies in the modern world.

1. The Birth of Electronic Circuits: Before PCBs

Before the invention of PCBs, electronic circuits were manually assembled. In the early 20th century, circuits were constructed by soldering wires directly to components. These components were mounted on wooden or metal panels, and connections were made using point-to-point wiring. This method was not only time-consuming but also prone to errors and mechanical failures.

2. Early Innovations: The Genesis of PCB Concepts

The concept of a printed circuit can be traced back to the late 19th century. Thomas Edison, the famed American inventor, experimented with chemical methods for creating electrical paths on a flat surface. In 1904, German inventor Albert Hanson developed a method for creating multiple layers of conductors separated by insulating material, resembling the modern multilayer PCB. Hanson’s work, however, did not lead to a commercial product, as the technology of the time was not yet capable of mass production.

3. The Turning Point: Paul Eisler’s Invention

The real breakthrough came in 1936 when Austrian engineer Paul Eisler invented the first true printed circuit board. Eisler, working in the UK, developed a method for printing conductive traces onto an insulating substrate. He used a process that involved etching copper foil to create a circuit pattern, which he then adhered to a non-conductive base material. Eisler’s invention was initially intended for use in radios, but its significance was not immediately recognized.

4. World War II: The Catalyst for PCB Adoption

The onset of World War II played a crucial role in the adoption of PCBs. The military needed reliable and compact electronic circuits for equipment such as radios and missile guidance systems. The traditional point-to-point wiring method was inadequate due to its bulkiness and susceptibility to failures in harsh environments. Eisler’s PCB technology provided a solution, offering a way to produce durable and compact circuits.

During the war, the U.S. military began adopting PCBs for their equipment, particularly in proximity fuzes for artillery shells. The demand for mass production and the need for reliability accelerated the development and refinement of PCB technology. By the end of the war, PCBs were well on their way to becoming a standard in electronics manufacturing.

5. Post-War Expansion: The Commercialization of PCBs

After World War II, the commercial potential of PCBs began to be realized. The post-war boom in consumer electronics, particularly in radios and televisions, created a demand for more efficient manufacturing methods. PCBs provided a solution by enabling the mass production of reliable and compact electronic circuits.

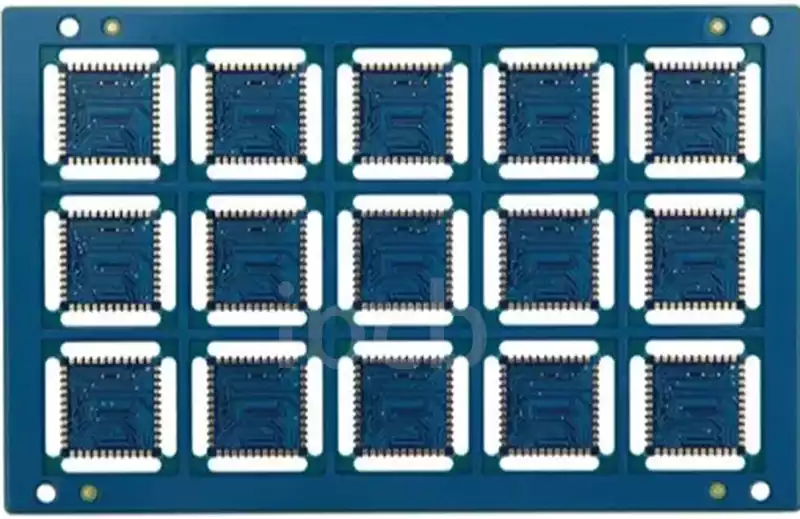

The 1950s saw significant advancements in PCB technology. The development of double-sided and multilayer PCBs allowed for more complex circuits to be created in a smaller space. Additionally, the introduction of automatic soldering techniques improved the consistency and reliability of PCB assembly. These advancements laid the foundation for the explosive growth of the electronics industry in the subsequent decades.

6. The Era of Miniaturization: PCBs in the Age of Semiconductors

The invention of the transistor in 1947 and the subsequent development of integrated circuits (ICs) in the 1960s revolutionized the electronics industry. These technologies allowed for the miniaturization of electronic components, enabling the creation of smaller and more powerful devices. PCBs played a critical role in this transformation by providing the necessary platform for mounting and connecting these tiny components.

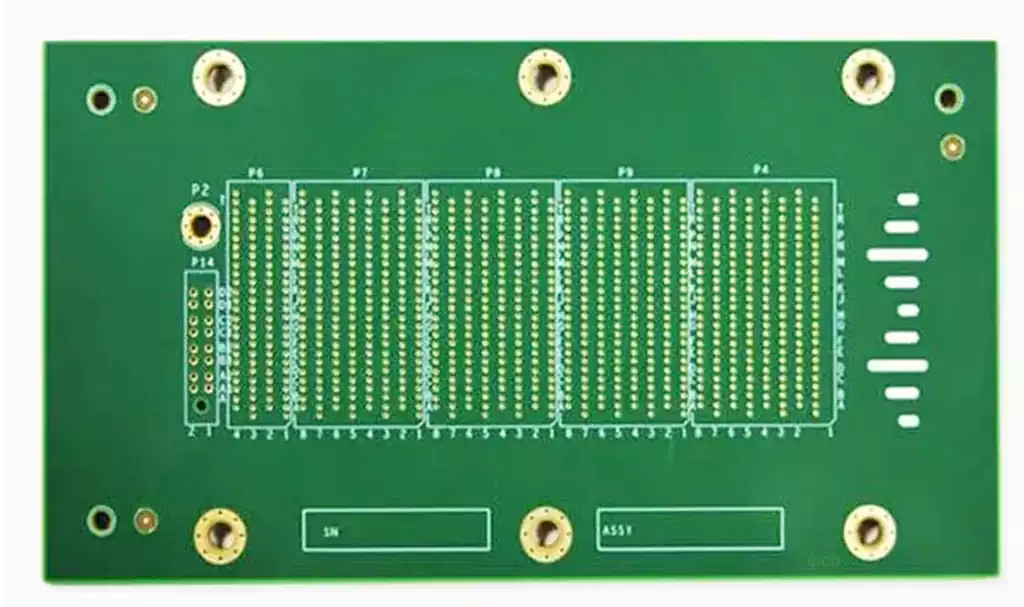

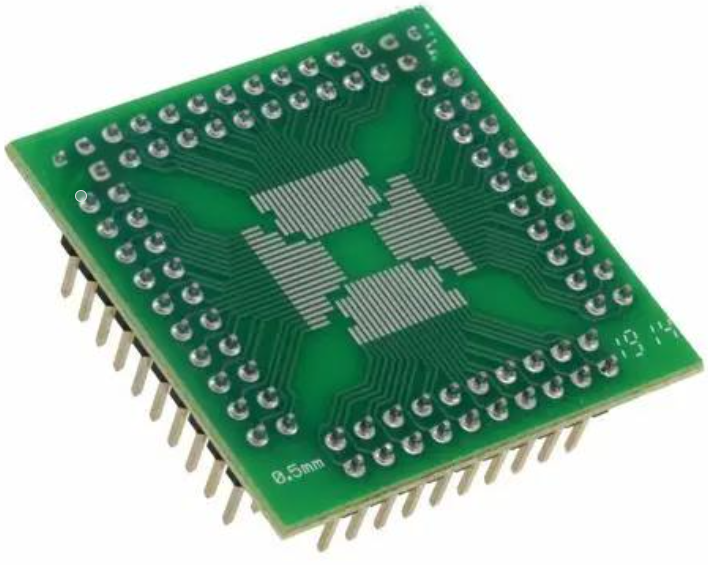

The 1970s and 1980s saw the rapid advancement of PCB technology in response to the demands of the burgeoning computer industry. The development of surface-mount technology (SMT) allowed components to be mounted directly onto the surface of the PCB, further reducing the size and weight of electronic devices. The increasing complexity of circuits also led to the widespread adoption of multilayer PCBs, which could accommodate more connections and components in a compact space.

7. The Rise of Modern PCB Manufacturing

As the demand for more sophisticated electronics grew, so did the need for advanced PCB manufacturing techniques. The 1990s and 2000s saw significant improvements in materials, design software, and manufacturing processes. The development of high-density interconnect (HDI) technology allowed for even more components to be packed onto a single board, enabling the creation of increasingly complex devices such as smartphones, tablets, and wearable technology.

The rise of computer-aided design (CAD) software revolutionized the design process, allowing engineers to create intricate circuit layouts with unprecedented precision. Advances in materials, such as the development of flexible and rigid-flex PCBs, expanded the range of applications for PCB technology, enabling its use in a wider variety of devices.

8. PCBs in the 21st Century: Challenges and Innovations

Today, PCBs are ubiquitous, found in virtually every electronic device. However, the industry faces new challenges and opportunities as technology continues to evolve. One of the key challenges is the need for environmentally friendly manufacturing processes. The traditional methods of PCB manufacturing involve the use of hazardous chemicals and generate significant waste. In response, the industry is exploring greener alternatives, such as the use of biodegradable materials and more efficient recycling processes.

Another area of innovation is in the development of advanced materials and technologies to meet the demands of emerging applications. For example, the rise of the Internet of Things (IoT) and 5G networks requires PCBs that can handle higher frequencies and more complex signals. This has led to the development of materials such as low-loss dielectrics and high-speed laminates, which can support these advanced applications.

Additionally, the push for miniaturization continues, with research ongoing into the development of ultra-thin PCBs and even three-dimensional (3D) printed circuits. These advancements are expected to drive the next generation of electronic devices, enabling the creation of even smaller, more powerful, and more versatile products.

9. The Global PCB Industry: An Economic Powerhouse

The PCB industry has grown into a global economic powerhouse, with major manufacturing hubs in Asia, particularly China. The rise of global supply chains and the demand for consumer electronics have driven the growth of PCB manufacturing in countries with cost advantages and strong manufacturing capabilities.

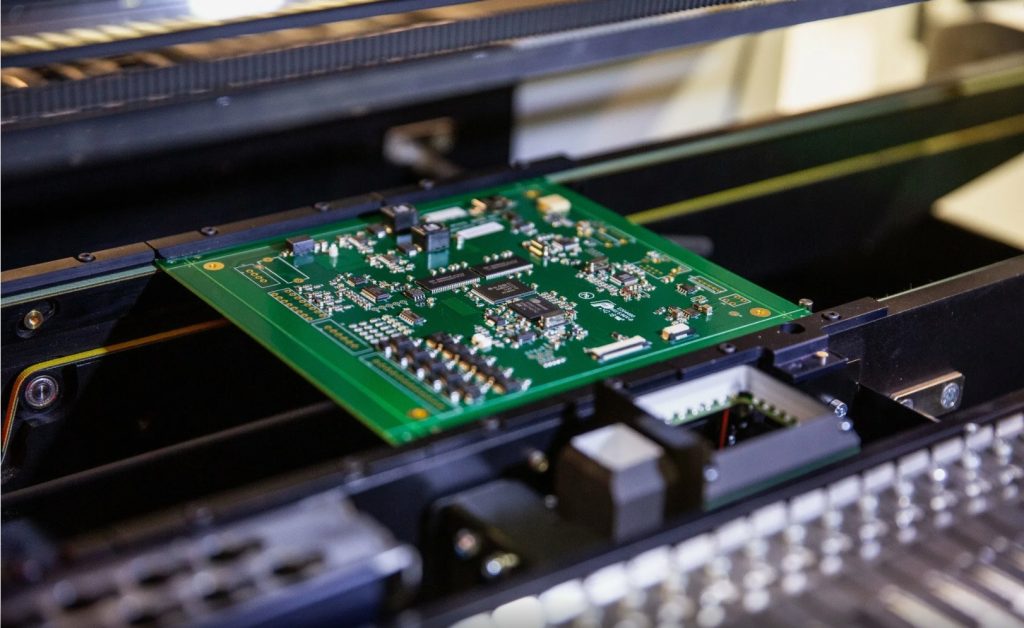

In recent years, the industry has also seen a shift toward more localized production, driven by concerns over supply chain resilience and the need for faster time-to-market. This trend has been accelerated by geopolitical factors and the impact of global events such as the COVID-19 pandemic. As a result, there is a growing emphasis on innovation in manufacturing processes, such as the use of automation and digitalization, to improve efficiency and flexibility.

10.The Future of PCBs

The story of PCBs is one of continuous innovation and adaptation. From their humble beginnings in the early 20th century to their role as the foundation of modern electronics, PCBs have undergone tremendous evolution. As technology continues to advance, the PCB industry will undoubtedly face new challenges and opportunities.

Looking ahead, the future of PCBs will likely be shaped by several key trends. The ongoing demand for miniaturization and increased functionality will drive further innovation in materials and manufacturing techniques. The push for sustainability will also play a critical role, as the industry seeks to reduce its environmental impact.

Moreover, the rise of new technologies such as artificial intelligence, quantum computing, and advanced robotics will create new demands and opportunities for PCB technology. These developments will require PCBs that can support increasingly complex and powerful electronic systems, pushing the boundaries of what is possible.

In conclusion, PCB Origin and Evolution are a testament to human ingenuity and the relentless pursuit of progress. As we look to the future, PCBs will continue to be at the heart of technological innovation, enabling the creation of the next generation of electronic devices that will shape our world.