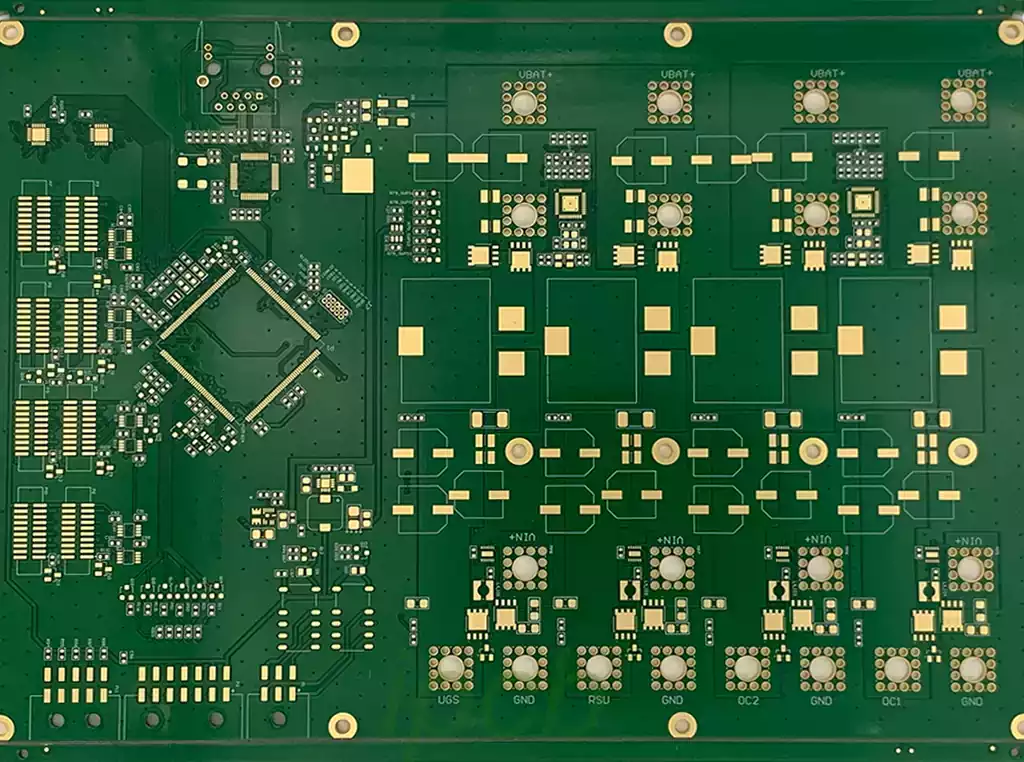

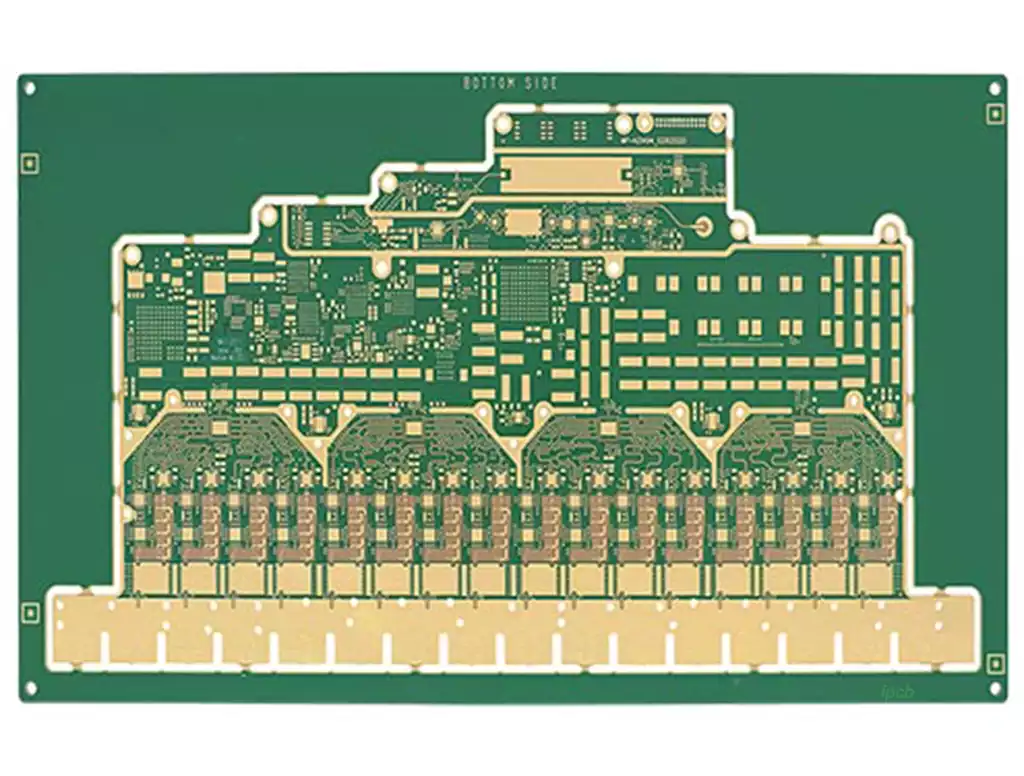

What is the PCB prototype? PCB prototype is an early PCB sample of a product, which aims to test the design concept and see if the product is feasible. Although most prototypes are only made to test basic product functionality, PCB prototypes still need to have some degree of functionality because PCB prototyping is made to test the overall functionality of the design.

During the PCB prototype production process, engineers can conduct experiments on different PCB designs and manufacturing specifications to find the most effective one.

Why do we need a PCB prototype?

Shorten time and save costs: In the process of designing PCBs, engineers perform multiple iterations before creating the final product, which can result in a longer timeline. However, PCB prototypes can help accelerate the entire design and manufacturing process by:

Complete testing and improved functionality: PCB prototypes can help PCB design engineers quickly and accurately test design issues. If this is not the case, discovering design defects would require more time. If not delivered in a timely manner, it may lead to customer dissatisfaction and result in loss of revenue.

Customers see the product in advance for better communication: Customers usually hope to see the product at multiple points during the production process, providing prototypes as an aid to better guide the design. It can also minimize communication with customers and the time they require for redesign.

Minimize rework: PCB prototype testing allows for inspection and testing of circuit boards before production, reducing rework. If defective products are put into production, it will take longer and incur more costs in the later stages.

The role of PCB prototypes

Verify the design: by making a circuit board prototype, the designer can find and correct defects or errors in the design at an early stage. This greatly reduces the cost and time to find and fix these errors at a later stage.

Functional Testing: Circuit board prototypes can be used to test the functionality of a product. For example, prototypes can be used to check that the individual components on a circuit board work as intended and that the product meets its design specifications.

Performance Testing: With a prototype, a series of performance tests, such as temperature variation tests, power variation tests, shock resistance tests, etc., can be performed to evaluate the board’s performance in a variety of environments and operating conditions.

Early Feedback: PCB Board prototypes allow designers and engineers to share design ideas and concepts with customers or potential stakeholders for early feedback and input.

Reduced Costs: Finding and fixing bugs in the early stages of product development is often more economical than in later stages. In addition, by using prototype circuit board, significant manufacturing cost savings can be realized by avoiding the need to discover problems after mass production.

Material and component selection: During the prototyping process, the performance of different materials and components can be tested and evaluated so that the most suitable ones can be selected before production.

Feasibility studies: In some cases, prototyping can also be used to assess whether a design or technology is feasible. For example, in projects involving extreme environments or special needs, it may be required to verify the feasibility of a design.

PCB Prototyping Process

The process of prototyping a PCB is not complicated, and the following are its basic steps:

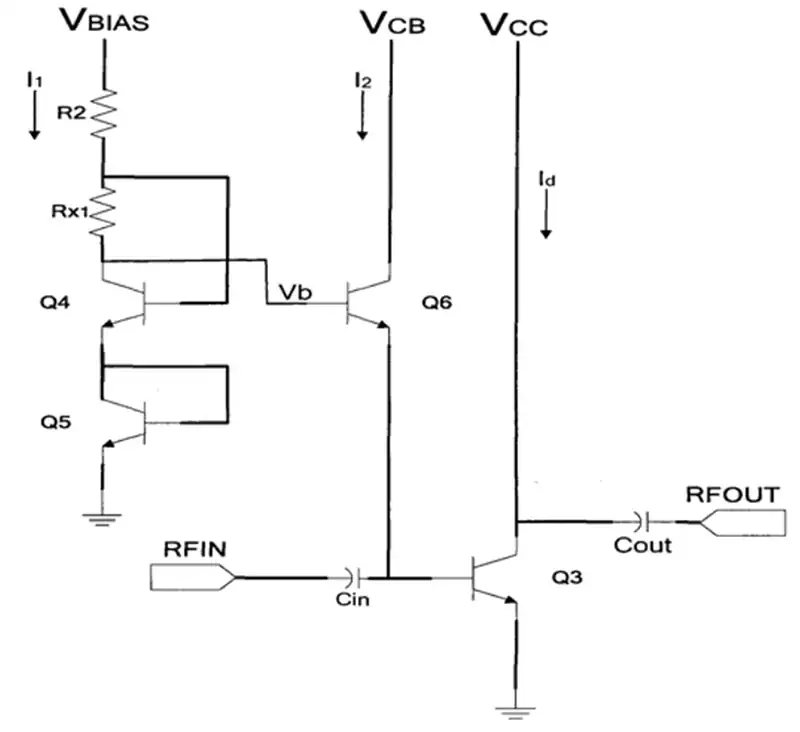

Design phase: Use professional software, such as Altium Designer or Eagle, to draw circuit diagrams and determine the component layout.

Prototyping: Give the design files to a professional PCB manufacturer and select the appropriate materials and processes according to the actual needs.

Component Soldering: Solder the required components onto the board to ensure they work properly.

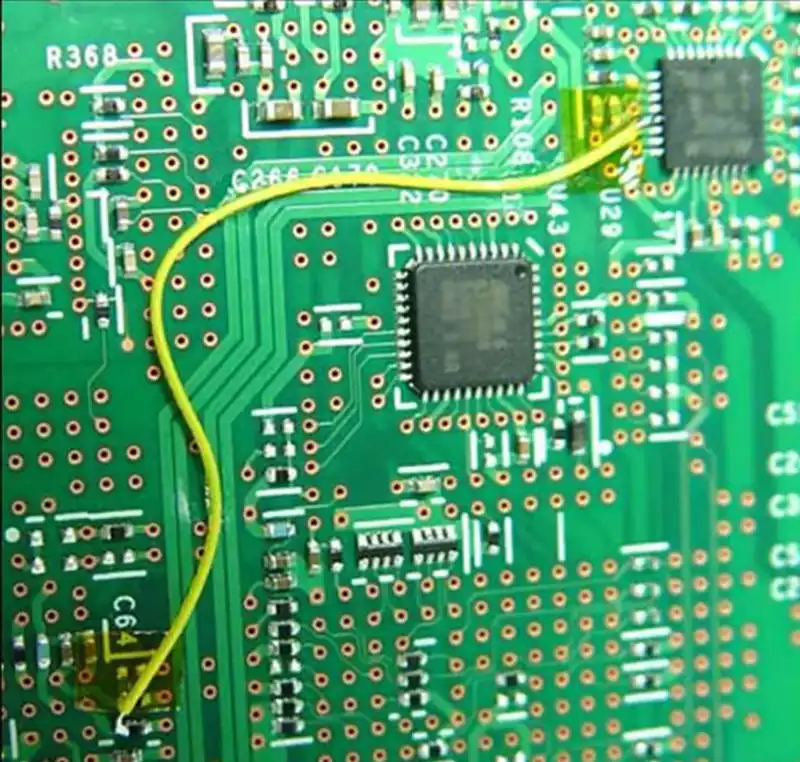

Testing and debugging: check the functionality of the circuit board to ensure that all components work properly.

Optimization and Improvement: Optimize and improve the prototype boards based on the test results.

How to choose the right prototyping PCB board?

Selecting the right PCB board prototype requires consideration of several factors.

Project Requirements: Define the project requirements and select a PCB that meets them.

Budget: Select the right material and process according to the budget.

Timeline: Consider the project timeline and select a manufacturer that can deliver on time.

Quality and Performance: Ensure that the quality and performance of the PCB circuit board prototype meet expectations.

Testing of PCB Prototypes

Testing the PCB prototype is a critical part of ensuring that it functions properly and performs as intended.During the testing process, attention needs to be paid to several aspects to ensure that the performance of the circuit board prototype is fully evaluated.

a. Professional test equipment, such as multimeters, oscilloscopes, signal generators, power meters, etc., need to be prepared for testing the electrical performance of the PCB prototype. This equipment can provide accurate measurement results to help us determine whether the circuit board prototype meets the design requirements.

b. The type and method of testing are also crucial. According to the characteristics of the PCB prototype, different test methods can be selected, such as functional tests, parametric tests, stress tests, etc. Functional testing mainly verifies whether the PCB circuit board prototype realizes the expected function; parametric testing measures the key performance parameters of the circuit board prototype, such as voltage, current, resistance, capacitance, etc.; stress testing tests the stability of the circuit board prototype under certain operating conditions.

c. In the testing process, you also need to pay attention to some details. For example, to ensure that the test environment is clean and tidy, to avoid the impact of external interference on the test results; test before the need for circuit board prototypes for pre-processing, such as aging, baking, etc., to eliminate potential pitfalls; test process should be carried out in strict accordance with the operating procedures, to avoid damage to the test equipment and the PCB circuit board prototypes; test after the need to analyze and summarize the results for the unqualified part of the improvement and optimization.

d. PCB prototype testing is not a one-time process. In the actual use of the process, but also needs to carry out regular maintenance and inspection to ensure its long-term stability and reliability. At the same time, it is also necessary to constantly update the test methods and equipment to adapt to the continuous development and progress of electronic technology.

PCB prototype is an indispensable part of the electronic product design process. It not only helps to verify the feasibility of the design but also reduces the cost of later modification and optimization. Through careful design and selection of appropriate materials and processes, iPCB specializes in producing high-quality PCB prototypes, ensuring that PCB circuit boards pass rigorous testing and evaluation, ensuring product reliability and stability.