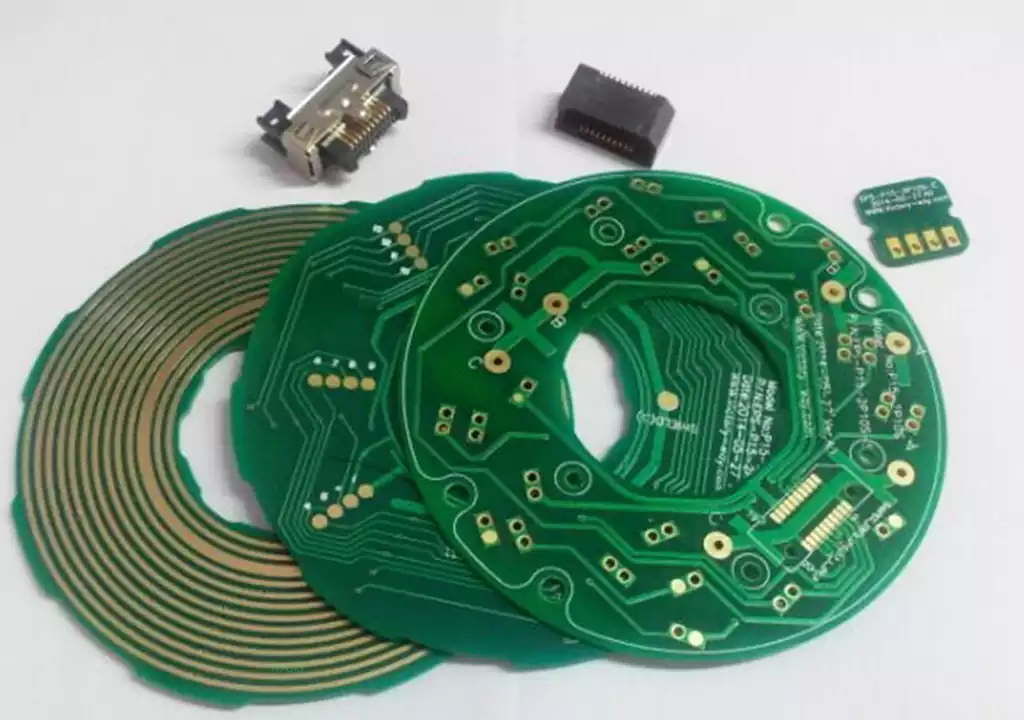

PCB slip ring, as a highly efficient electrical transmission device, are widely used in scenarios that require continuous rotation while maintaining electrical connections.Compared to conventional slip rings, they feature a more compact and integrated design, enabling a brushless connection between the wires and the printed circuit board, thus ensuring the stability and reliability of power transmission.

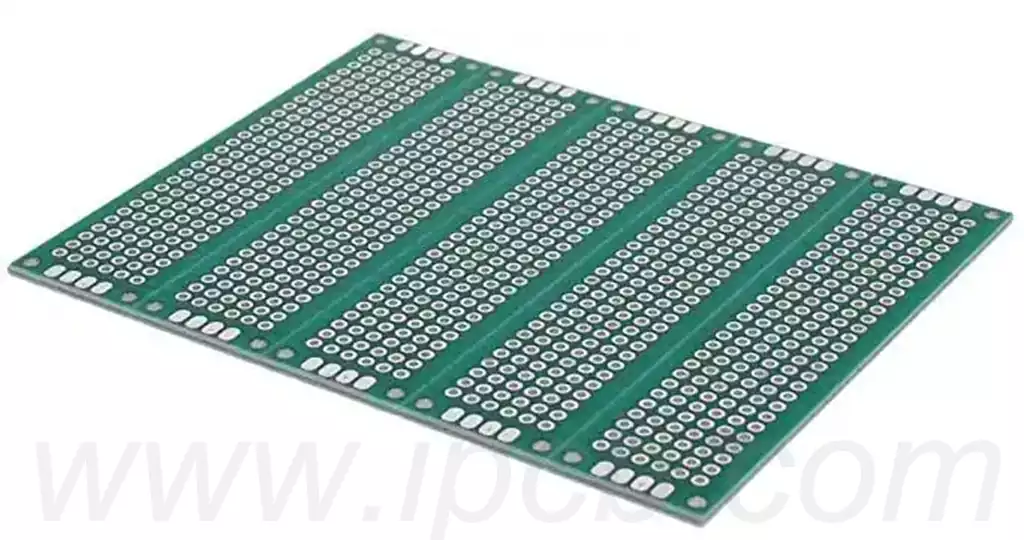

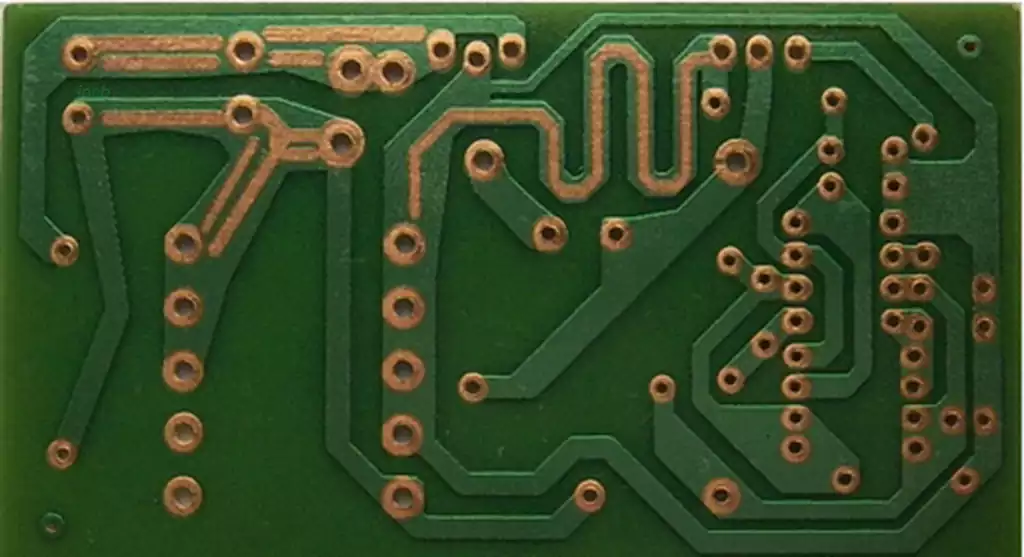

This type of slip ring mainly consists of a brush assembly and a printed circuit board, of which the printed circuit board occupies an important position in the electrical and electronic industry with its unique advantages. Its surface is covered with a thick copper or gold plating layer, which, combined with the characteristics of the printed circuit board itself, makes this kind of slip ring characterized by high wear resistance and high hardness.

Structurally, pcb slip rings can be categorized into split conductive slip rings or individual conductive slip rings, which can be adapted to the needs of different application scenarios. Its compact design allows it to fit into smaller spaces, thus saving valuable installation space.

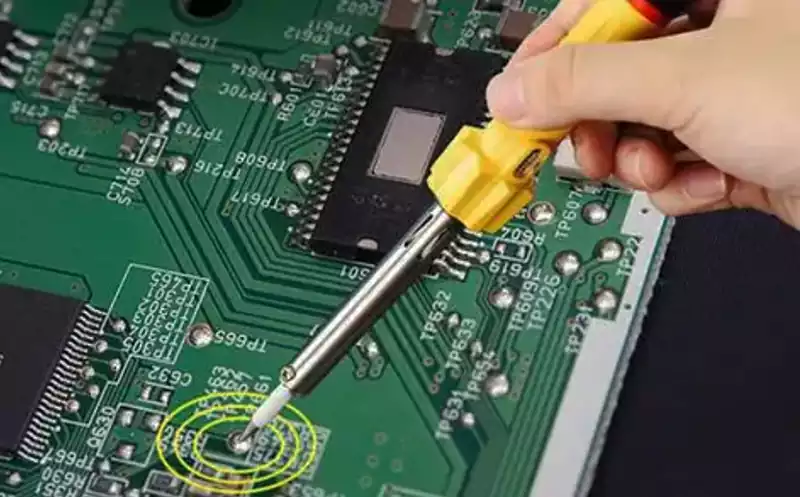

In addition, this slip ring offers many advantages such as low maintenance, reliable electrical connections and customizable configurations. Since there are no brushes or moving parts as in conventional slip rings, wear and tear is greatly reduced, resulting in lower maintenance requirements and longer service life. At the same time, the printed circuit board design ensures a stable and reliable electrical connection, minimizing signal loss and interference.

PCB slip rings utilize advanced manufacturing processes and materials to ensure excellent performance.The printed circuit board, as its core component, is characterized by excellent conductivity and compact structure. By laying out fine conductive lines on the circuit board, it is capable of realizing multi-channel, high-density electrical connections, which meets the needs of various complex application scenarios. It also adopts a brushless design, avoiding the problem of brush wear in traditional slip rings. This design not only reduces maintenance costs, but also increases the service life of the slip ring.

In terms of application areas, printed circuit board slip rings are widely used in rotating cameras, robotics, wind turbines, medical equipment and packaging machinery. These applications require the transmission of power and control signals between stationary and rotating components, and printed circuit board slip rings fulfill these requirements perfectly.

PCB slip rings have become an important device in the field of electrical transmission due to their unique structure and multiple applications. With the continuous progress of technology and the continuous expansion of application scenarios, it will continue to play an important role in providing strong support for the development of various industries.