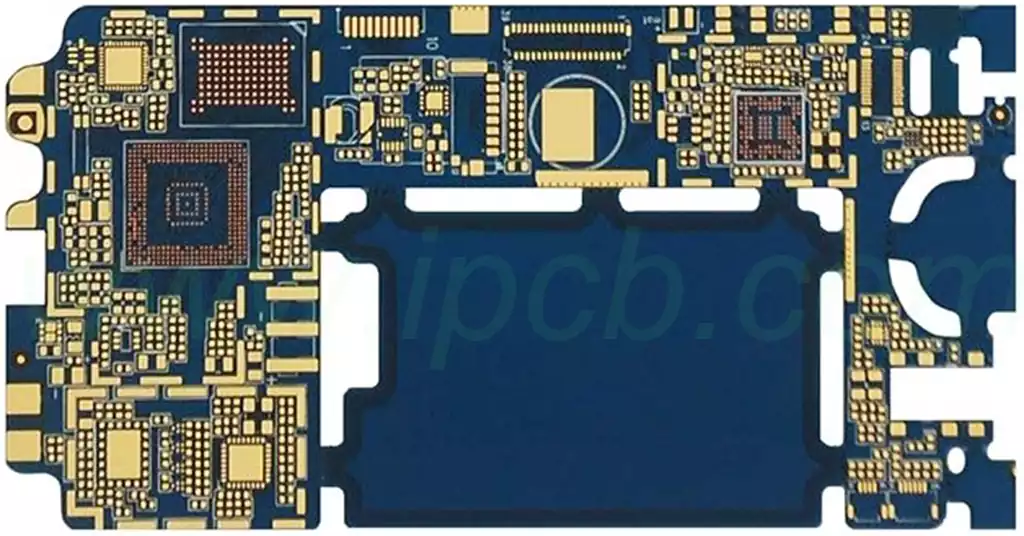

Thick film ceramic PCB is an advanced circuit board technology that combines the excellent properties of ceramic materials with the flexibility of printed circuits. These boards are widely used in many fields because of their excellent high-temperature resistance, high insulation, excellent thermal conductivity, and high reliability.

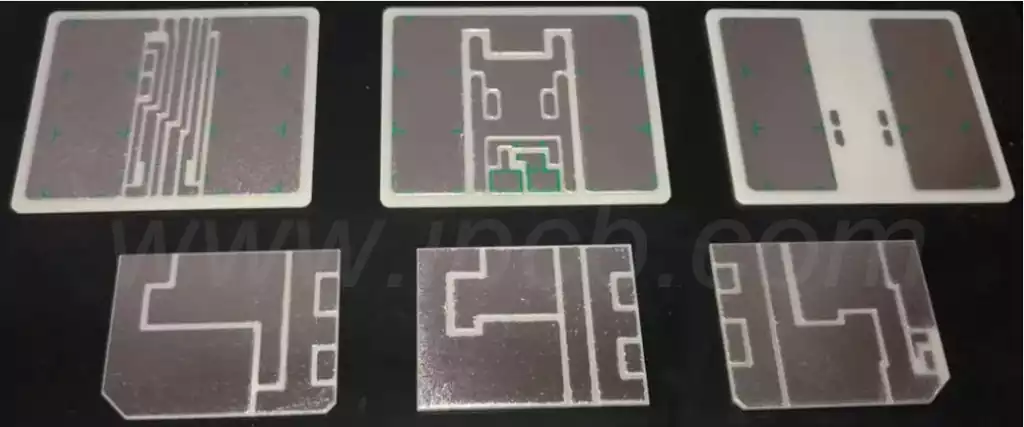

Thick film ceramic PCB adopts ceramic material as the substrate and prepares circuits by printing technology. It has the following main characteristics:

High-temperature resistance: it can withstand higher temperatures and is suitable for applications in high-temperature environments. This makes it a wide range of applications in areas such as automotive electronics, industrial control, and aerospace.

High Insulation: Ceramic materials are highly insulating and can effectively isolate circuits, reducing the risk of electromagnetic interference and electric shock. This makes it excellent in high-voltage, high-current applications.

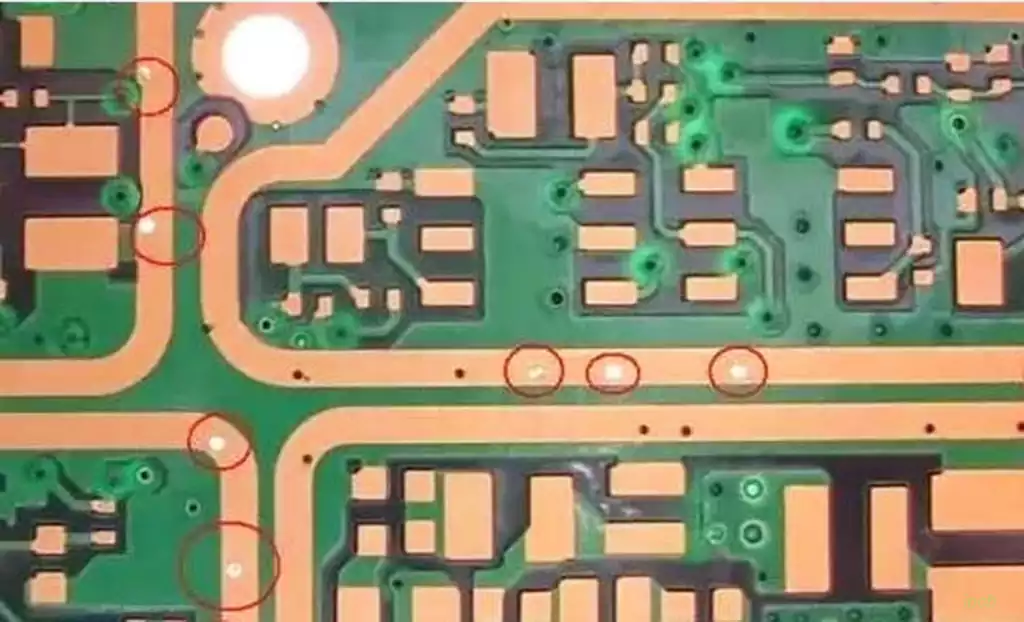

Excellent thermal conductivity: ceramic materials have high thermal conductivity, which can effectively transfer heat out, reduce the operating temperature of the circuit, and prevent thermal failure. This is very favorable for the thermal design of high-power electronic devices.

High reliability: The structure is stable and not easily affected by the environment, and has high reliability and stability. This makes it ideal for applications that require long-term stable operation.

Thick film ceramic PCB is widely used in a variety of fields due to its outstanding performance:

Automotive electronics: Able to withstand the temperature and vibration of the complex environment inside a car, they are suitable for applications such as automotive lighting, sensors, and safety systems.

Industrial Controls: In industrial controls, high-temperature stability, and high insulation properties make them ideal for motor control, power supply, and automation equipment.

Aerospace: In the aerospace field, high-temperature resistance and light weight make it ideal for avionics and satellite communication systems.

Communication equipment: In the field of communication equipment, excellent thermal conductivity and high insulation properties make it ideal for 5G base stations, fiber optic equipment, and communication antennas.

Medical Equipment: In the field of medical equipment, biocompatibility and high reliability make it ideal for medical instruments and implantable devices.

Military and Aerospace: In the military and aerospace field, high-temperature stability and high reliability make it ideal for missile guidance systems, satellite navigation systems, and military electronic equipment.

As an advanced circuit board technology, thick film ceramic PCB has the following advantages over traditional FR4 PCB:

Longer service life: able to operate stably for long periods in high-temperature environments, which improves the service life of the product.

Better electrical performance: high insulation performance and low dielectric loss make it have lower signal transmission loss and better anti-electromagnetic interference ability, improving the electrical performance.

Stronger thermal conductivity: Higher thermal conductivity can effectively transfer heat out, lowering the operating temperature of the circuit and preventing thermal failure. This is very favorable for the thermal design of high-power electronic devices.

Smaller size and weight: Thick film ceramic PCB adopts a thin sheet-like structure, compared with the traditional FR4 PCB board can be thinner, thus reducing the size and weight of the product, which is conducive to the realization of lightweight and miniaturization of electronic equipment.

A wider range of applications: It excels in applications requiring high temperature, high voltage, high current, and high reliability, and has a wider range of applications than traditional FR4 PCB plates.

With its excellent performance and wide range of applications, thick film ceramic PCB board has become one of the important development directions of the electronics industry. With the continuous progress of science and technology and changing market demand, thick film ceramic PCB will play a more important role in the future. Whether it is automotive electronics, industrial control or aerospace, communications equipment, and other fields, thick film ceramic PCB will play a key role in promoting technological progress and industrial development. At the same time, with the increasing demand for recyclable and environmentally friendly materials, the environmental friendliness and recyclability of thick-film ceramic PCBs will also become an important advantage for their future development.