Introduction

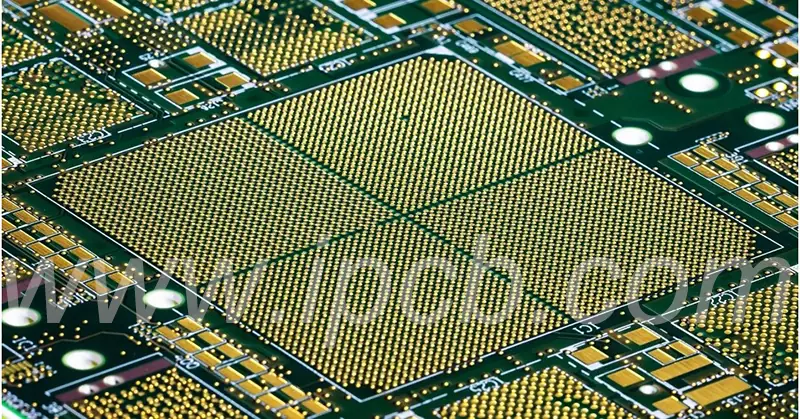

In today’s world, electronic devices have become an integral part of our daily lives. From smartphones to smart homes, these devices rely on printed circuit boards (PCBs) to function efficiently. However, with the increasing complexity and miniaturization of electronics, ensuring their reliability and longevity has become a significant challenge. This is where PCB protection boards play a crucial role.

Understanding PCB Protection Boards

PCB protection boards, also known as circuit protection boards or simply protection boards, are essential components designed to safeguard electronic circuits from various types of damage. These boards are typically installed between the power source and the electronic device, serving as a barrier against overvoltage, overcurrent, short circuits, and other potential hazards. PCB protection boards achieve this by employing a range of protective measures, including fuses, surge suppressors, voltage regulators, and thermal cutoffs.

Types of PCB Protection Boards

There are several types of PCB protection boards available, each tailored to specific applications and environments. For instance, automotive electronics often require protection against voltage spikes and electromagnetic interference (EMI), leading to the development of specialized automotive protection boards. Similarly, industrial applications may demand ruggedized protection boards capable of withstanding harsh operating conditions such as extreme temperatures, moisture, and vibration.

Importance of PCB Protection Boards

The importance of PCB protection boards cannot be overstated, especially in today’s interconnected world. Without adequate protection, electronic devices are vulnerable to damage from power surges, voltage transients, and other electrical anomalies. This not only compromises the performance and reliability of the devices but also poses safety risks to users. By integrating PCB protection boards into electronic designs, manufacturers can enhance the durability, safety, and overall quality of their products, thereby enhancing customer satisfaction and brand reputation.

Key Features to Consider

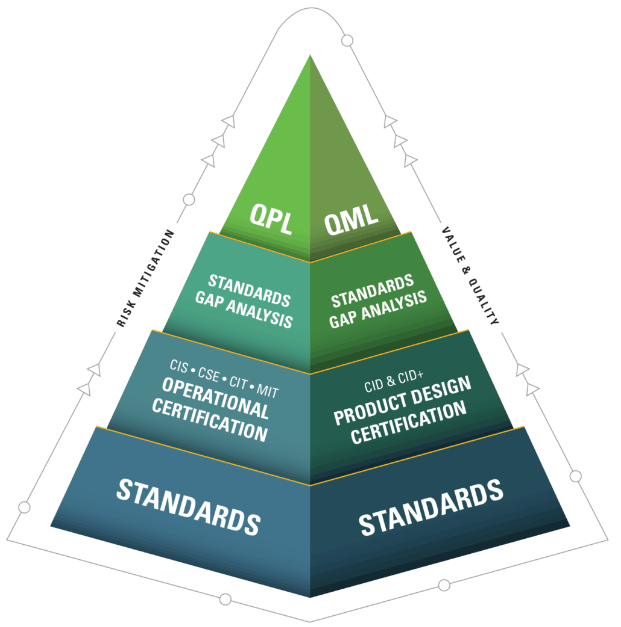

When selecting PCB protection boards for a particular application, several key features should be taken into account. These include:

- Voltage Rating: Ensure that the PCB protection board is rated for the expected voltage levels within the circuit.

- Current Handling Capacity: Verify that the board can handle the maximum current expected during normal operation and fault conditions.

- Response Time: Consider the response time of the protection mechanisms to ensure timely intervention in the event of a fault.

- Environmental Protection: Choose boards with appropriate ingress protection (IP) ratings for the intended environment to prevent damage from dust, moisture, and other contaminants.

- Compliance Standards: Confirm that the PCB protection board complies with relevant industry standards and certifications to guarantee performance and safety.

Applications of PCB Protection Boards

The versatility of PCB protection boards makes them indispensable across a wide range of industries and applications. Some common applications include:

- Consumer Electronics: Smartphones, tablets, laptops, and other consumer electronics benefit from PCB protection boards to safeguard against power surges and other electrical hazards.

- Automotive Electronics: From engine control units (ECUs) to infotainment systems, automotive electronics rely on protection boards to ensure reliable performance in the face of harsh automotive environments.

- Industrial Automation: PLCs, motor drives, and industrial sensors utilize protection boards to withstand rugged industrial conditions and maintain uptime.

- Renewable Energy: Solar inverters, wind turbines, and battery management systems (BMS) employ PCB protection boards to maximize energy efficiency and system reliability.

- Telecommunications: Networking equipment, base stations, and communication devices are protected by PCB protection boards to maintain uninterrupted connectivity.

Future Trends and Innovations

As electronic devices continue to evolve, so too will the field of PCB protection. Emerging trends and innovations in this space include:

- Integration of Intelligent Protection: PCB protection boards with built-in diagnostics and prognostics capabilities to predict and prevent potential failures before they occur.

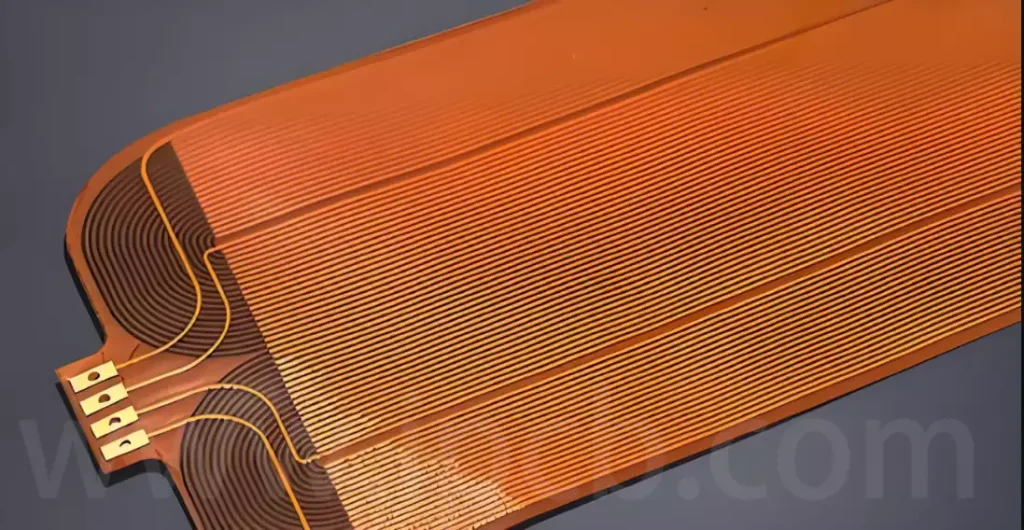

- Adoption of Advanced Materials: Use of advanced materials such as nanocomposites and polymers to enhance the performance and durability of protection boards.

- Development of Multifunctional Protectors: PCB protection boards that combine multiple protection functions into a single device, reducing complexity and footprint.

- Embrace of IoT Connectivity: Integration of PCB protection boards with Internet of Things (IoT) platforms for remote monitoring, control, and predictive maintenance.

Conclusion

In conclusion, PCB protection boards play a vital role in safeguarding electronic circuits against various forms of damage, ensuring their reliability, longevity, and safety. As electronic devices become increasingly integral to our lives, the demand for effective protection solutions will only continue to grow. By staying abreast of the latest trends and innovations in PCB protection, manufacturers can ensure the continued success and resilience of their electronic products in an ever-changing landscape.