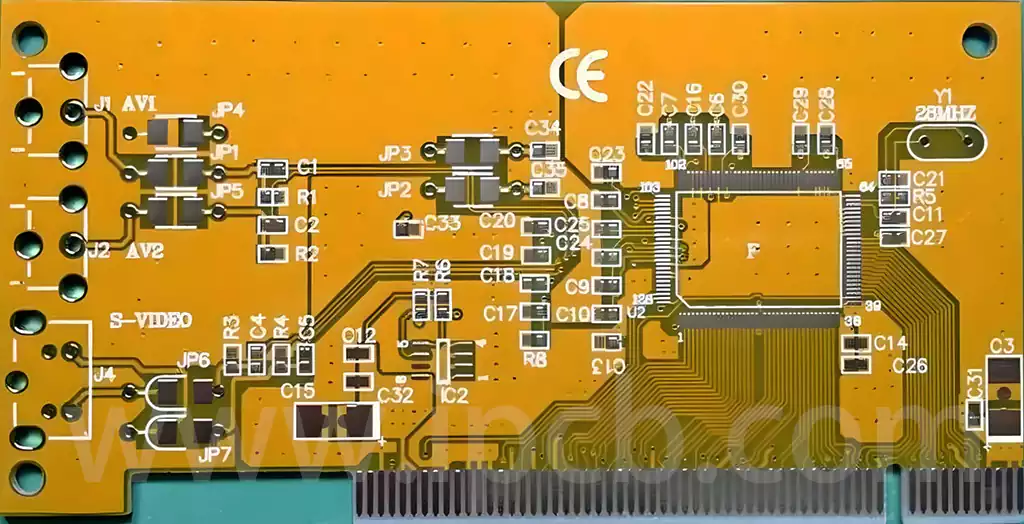

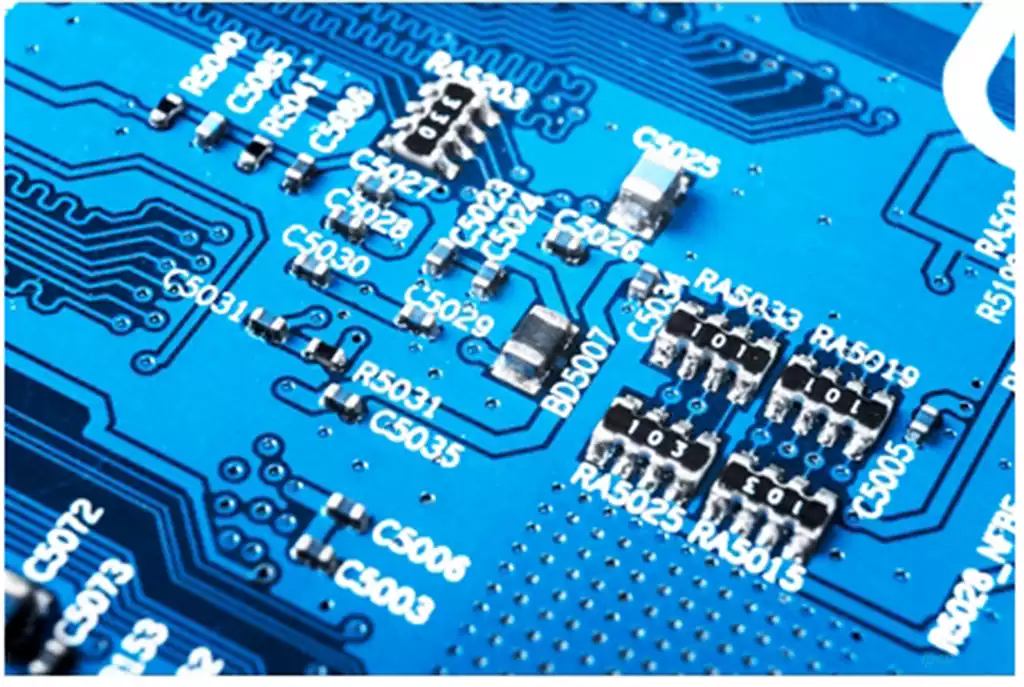

Printed circuit boards are the basis of modern electronics. As such, they require special care and precision in their production and manufacturing processes. One of the most critical procedures to consider is the process of cutting pcb.

Why do PCB needs to be cut?

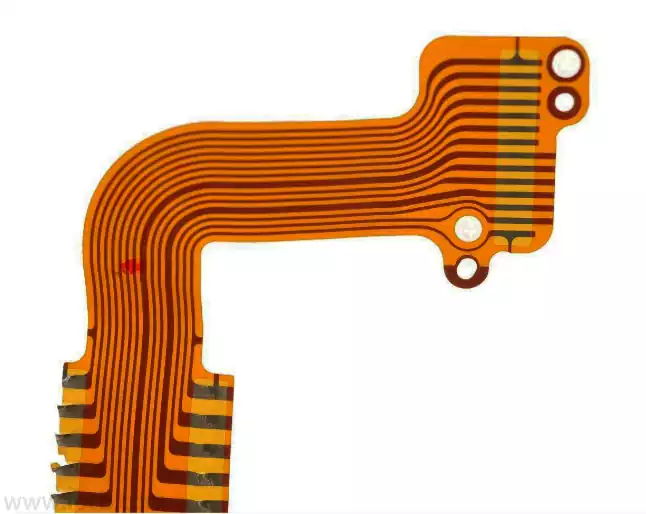

There are many different types of circuit boards. As a result, each type has specialized applications. For example, PCB can be rigid or flexible, single-layer or multi-layer. However, despite the PCB’s consistency or material, some of these PCB’s use cases may overlap.

However, we need to cut and sand them in a way that suits the last use case. In addition, we may find that the circuit board has unnecessary excess material after placing its components. Cutting the PCB will make its space more efficient and uniform.

In addition, cutting homemade PCB substrate allows you to save on material costs. You can reuse the material cut from the PCB and integrate it into your other projects.

Methods of shape cutting pcb

- Straight line cutting (V-cutting): This is the most common type of cutting. By using a cutting tool or V-cutter, straight cuts are made along the edge of the PCB board or a specified cut line to achieve the desired size and shape.

- Milling Cutting: For PCB boards that require more precise shapes and hole positions, milling cutting is often performed using a CNC milling machine. According to the design documents, a rotary tool is utilized to remove excess material from the PCB board to achieve the desired shape and size.

- Wire Cutting: Certain complex pcb plate may require internal or complex curves to be cut. This can be done by using wire cutting technology, which cuts the PCB along a predetermined path by means of a high-speed fine wire cutter. Wire cutting can achieve high precision and complexity.

- Laser cutting: Laser cutting is a non-contact cutting technology that can achieve high precision and complex shapes. Through the heat of the laser beam, the material on the PCB is vaporized or melted to achieve the desired shape cut.

The proper functioning of printed circuit boards relies on the synergistic action of a variety of materials, where the substrate holds circuits such as copper, lead and tin. In most cases, cutting PCBs is a relatively safe operation. However, it is important to recognize that if a component or connection is inadvertently severed during the cutting process, this can result in a dysfunctional PCB.

To ensure the safety of the cutting pcb process, operators need to take a number of precautions. They should use specialized cutting equipment and tools, which are often equipped with precise control systems and safety guards to minimize mishandling and potential risks.