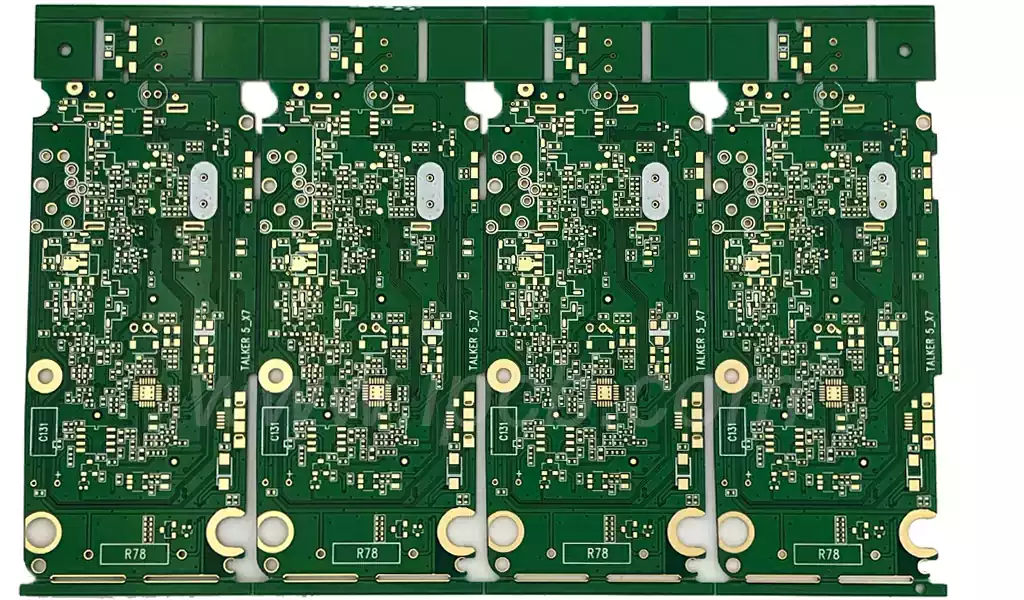

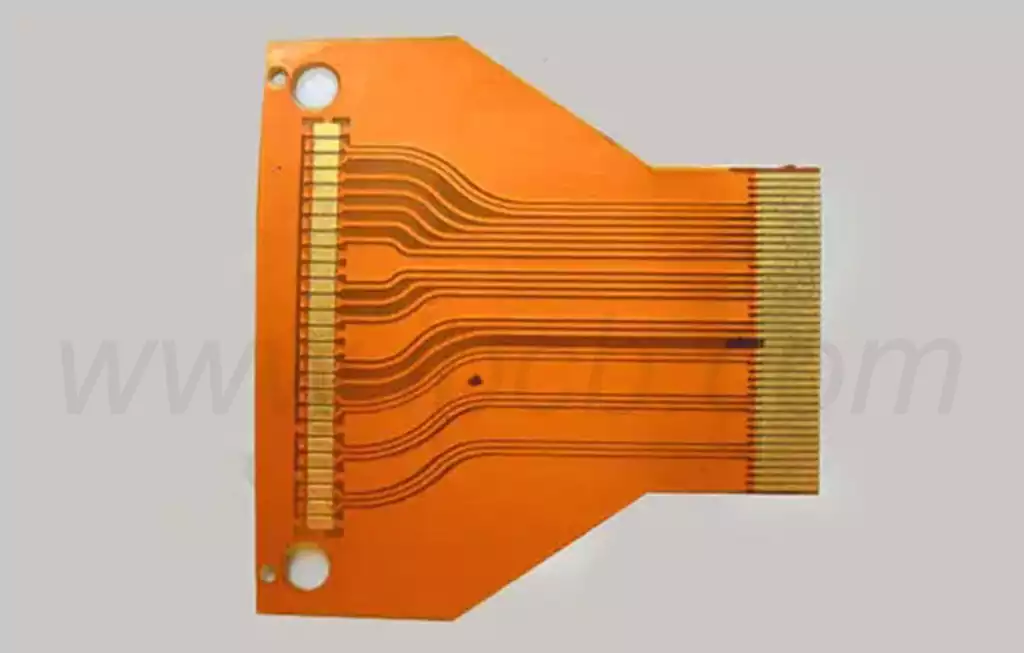

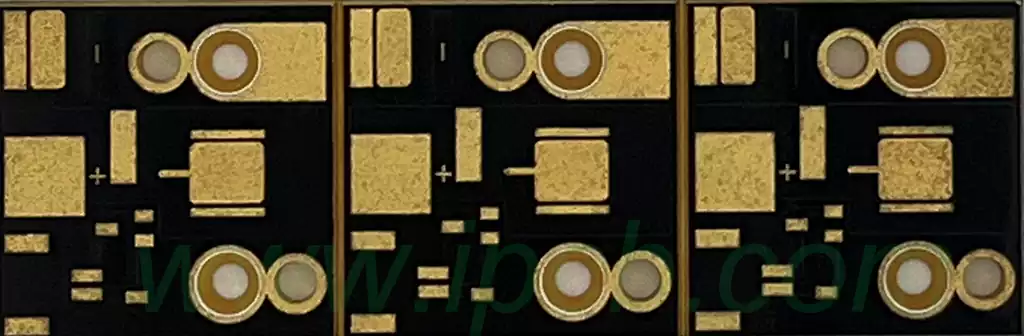

PCB silver plating is the plating of silver on the circuit board, which can play a role in protecting the pads and increase the conductivity of the circuit board. The advantage of silver plating is the ability to control board impedance and reduce signal attenuation of high frequency signals. In addition, silver plating has good corrosion resistance and reliability, which can enhance the stability and reliability of the circuit board.

The main purpose of silver plating is to improve the conductivity of the conductor. If the conductor’s conductivity is poor, the temperature of the connection area will rise rapidly, which may burn out the connector. For this reason, silver plating is often applied to connector parts that are subjected to high currents, such as the connection terminals of automobile charging guns. However, the high cost of silver makes the application of silver plating somewhat limited.

Applications and Advantages of pcb silver plating

Silver is one of the most commonly used conductive materials in the manufacture of printed circuit boards, and is widely used in key components such as circuit leads, pads and electrodes. Compared with other conductive materials, silver has the following advantages:

- High conductivity: the conductivity of silver is higher than copper, and has a better ability to migrate electrons, so the use of silver wires can effectively improve the transmission rate and stability of the circuit.

- Excellent weldability: silver has a low surface tension and high wettability, can effectively reduce the thermal stress in the welding process. At the same time, silver’s low oxidizability, easy to weld at high temperatures, can reduce welding defects.

- Good processability: compared with other highly conductive materials, silver is easier to process into complex shapes of wires and electrodes, while its surface processing is also easier to realize.

- Highly reliable: Compared with Al circuit, the adsorption of silver circuits presents different characteristics, which can effectively prevent undesirable phenomena such as adsorption and electromigration, thus improving the reliability of the circuit.

Toughening is the process of applying a layer of solder paste to the circuit board pads for soldering components. Ferry tin is an essential part of the manufacturing of electronic products, it can be components and circuit board soldering firm, so as to complete the circuit connection. The quality of the soldering paste has a direct impact on the reliability and stability of electronic products, so the quality of the soldering paste is very critical.

What is the difference between tin plating and silver plating

- Tin plating and silver plating of different materials

Tin plating usually uses tin and steel composite materials for plating treatment, while silver plating uses pure silver or silver alloy as the plating material. Due to the difference in materials, the appearance and performance of tin plating and silver plating also differ. - Performance Differences

The corrosion resistance, thermal conductivity, electrical conductivity and anti-wear properties of tin and silver plating are different. Tin corrosion resistance and wear resistance is better, but the electrical conductivity and thermal conductivity is slightly inferior. Silver has excellent electrical and thermal conductivity, but poor oxidation resistance, susceptible to chemical reactions and corrosion. - Different application scenarios

Tin plating is usually used in the manufacture of metal products surface treatment, such as cans, pots and pans, shaped fittings, etc., in order to protect the metal surface, improve its corrosion and wear resistance. And silver plating is mainly used in high-end electrical appliances, handicrafts, jewelry and other fields to show its elegant, gorgeous appearance and good conductivity. - Different construction methods

Tin plating and silver plating construction methods are different. Tin plating is usually electroplating method, electrolytic treatment in the tin electrolyte, tin plating layer deposited on the metal surface. Silver plating is generally used in chemical plating and vacuum coating technology, through chemical reaction or high temperature vacuum evaporation of silver layer plated on the surface of the substrate.

In the field of electronics manufacturing, pcb silver plating and tin plating as the choice of conductive materials, each has its own unique advantages and applicable scenarios. As technology continues to evolve, they will continue to play an important role in the stability and reliability of electronic products.