PCB terminal strip refers to the connection terminals on the PCB board, usually used to connect to other circuits or devices. It is connected to other electronic components through various interfaces (such as pins, terminals, etc.). This design not only improves the stability of the connection, but also facilitates maintenance and replacement at a later stage.PCB circuit board terminals are a type of interface assembly used to connect electronic components, external cables or devices. They are usually fixed to the PCB and provide a simple, reliable way to connect circuit boards to other components.

Principle of pcb terminals

Often, when we disassemble the keyboard of a general-purpose computer, we find a soft film (i.e., a flexible, insulating substrate material) with a silver-white conductive pattern and key layout printed on it. This pattern is created by screen-printing techniques, so we call this type of printed circuit board a flex-silver paste printed circuit board. However, the printed circuit boards on the various types of computer motherboards, graphics cards, network cards, modems, sound cards, and household appliances seen in computer cities are different. Their base materials are paper-based (commonly used for single-sided boards) or glass cloth-based (commonly used for double-sided and multilayer boards), which are pre-impregnated with phenolic or epoxy resins, and then copper foils are pasted on one or both sides of the surface, and then laminated and cured. These sheets with copper foil are called rigid boards, and when processed into printed circuit boards, they are called rigid printed circuit boards. If there is a line pattern printed on only one side, we call it a single-sided printed circuit board; if there is a line pattern on both sides and double-sided interconnections are achieved through metallised holes, it is called a double-sided board. If a double-sided board is used as the inner layer, two single-sided boards as the outer layer, or two double-sided boards as the inner layer, two single-sided boards as the outer layer, and through the positioning system and the insulation bonding material alternating combinations, and at the same time in accordance with the design requirements of the conductive pattern interconnections, the formation of four-layer, six-layer and other multi-layer printed circuit boards. Currently, there are more than 100 layers of practical printed circuit boards.

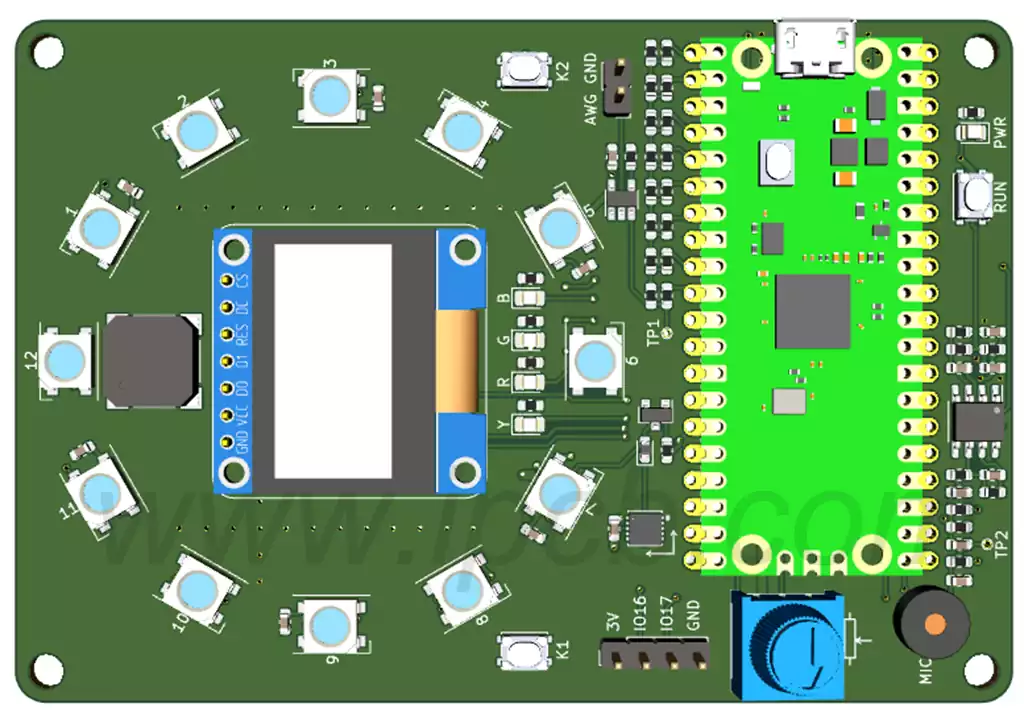

PCB terminals are commonly available in sizes such as 3.50mm, 3.81mm, 5.00mm, 5.08mm, 7.50mm, 7.62mm, and so on. According to the different types, PCB terminals can be divided into plug-in, screw, spring and fence type terminals.

The plug-in terminal series covers a wide range of pin pitches,including 3.5, 3.81, 5.0,5.08, 7.5 and 7.62 mm, with wire counts ranging from 2 to 24 wires. These terminals are equipped with sockets with screw fixing for vibration-resistant connections. The plugs use side connection technology, i.e. the direction of the screws is perpendicular to the direction of wire entry, ensuring a robust connection.

In the electronics industry, screw terminals have always occupied an important position as key components of printed circuit boards.Its structure is robust and designed for easy wiring, while ensuring the reliability and solidity of the screw connection.The terminals offer unique advantages in terms of compactness and reliable connection. The wire clamp lifting principle ensures reliable wiring and provides a large wiring capacity. Separate design of the soldering pin from the clamping body avoids damage to the soldering point when tightening the screw.The rugged housing and precise pin spacing further enhance its performance.

The spring-loaded printed circuit board terminals offer a wide range of pitch options, such as 2.54 mm, 3.50 mm, 5.00 mm, 7.50 mm and 7.62 mm. These terminals plug directly into single-core wires without the need for auxiliary tools and, for smaller wires, can be clamped with manually operated clips. The keyless design reduces the height of the terminals significantly, and the wires can be easily removed by applying light pressure with a screwdriver when retracting the wires. Spring-loaded terminals are usually made up of several single pieces, and the wiring is ideal for communication systems, lighting systems, monitoring systems, and building wiring. At the same time, a variety of wiring direction makes it easy to assemble in a small space, can be arbitrarily combined with the number of contacts, easy to operate, to meet the needs of high-density wiring.

The model code of LW fence type terminal block is LW, the code of the middle pin position is C, the code of the side pin position is B, the code of the fixed position is M, the code of the curved pin type is R, and the code of the soldered wire type is Q. The structure of LW fence type products is simple and clear, and it adopts the board type pressing method, which is both intuitive and firm. They are available in a wide range of wire diameters from 0.5 mm² to 6 mm².

Installation steps for PCB terminal strip:

Preparation

Before proceeding with the installation, you first need to prepare the required tools and materials, including PCB terminal block, electronic components, soldering tools, screwdrivers and so on. At the same time, make sure the working environment is neat and tidy for operation.

Check the PCB terminal block

Before installation, carefully check the quality and specifications of the PCB terminal strip to ensure that it meets the design requirements. Check whether the terminals are damaged or missing and make sure that all interfaces function properly.

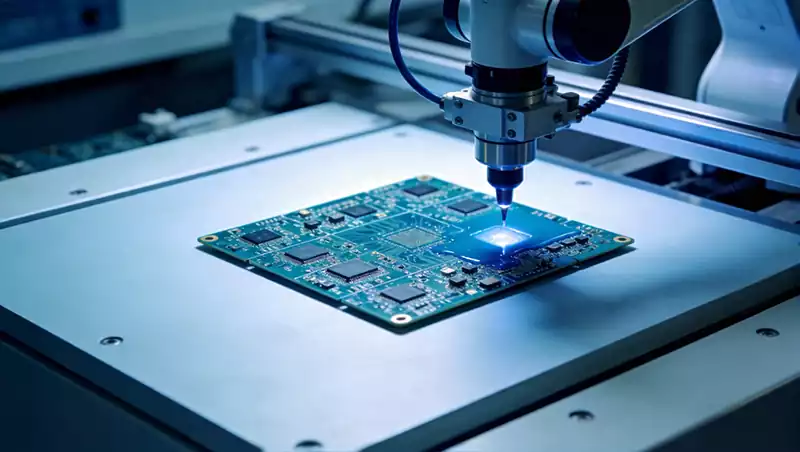

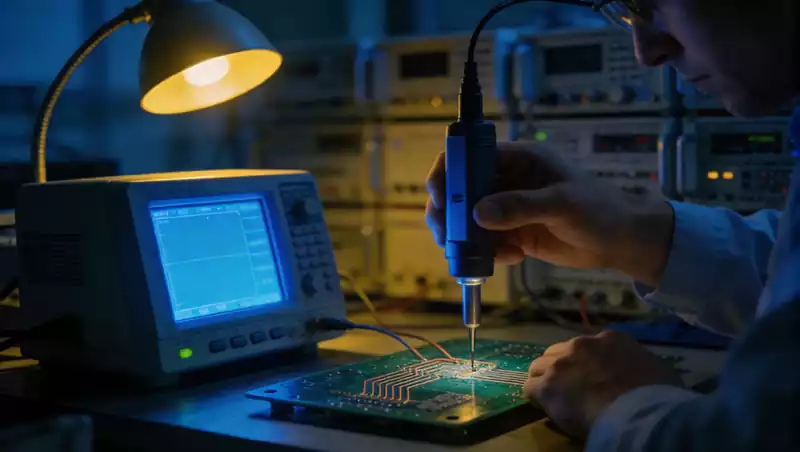

Positioning and Soldering

Place the terminal block at the intended location on the PCB to ensure alignment. A fixing jig or tape can be used to temporarily fix the position. After confirming that there are no errors, use a soldering tool to solder the pins of the terminal board to the pads on the PCB, making sure that the solder joints are even and firm.

Fixing with screws (if applicable)

If the PCB terminal block design includes screw fixing holes, you can use screws to fix the terminal board to the PCB. This step helps to increase the structural strength of the entire circuit and improves the durability of the device.

Checking the Connections

After the installation is complete, carefully check that all solder joints and connections are secure and free of false soldering or short circuits. You can use a multimeter to perform an electrical test to ensure that the wiring is connected properly.

Installation of other components

After confirming that the PCB terminal strip installation is complete, you can proceed to install other electronic components.Take care to ensure that all connections are clear and unambiguous during the assembly process to avoid problems in subsequent use.

Final Test

After all installations have been completed, perform a final system test. Check the functionality of the device and ensure that the PCB terminal strip and its connected components are working properly. This test can effectively identify potential problems and solve them in time.

Main Functions of PCB Terminal Blocks

Electrical Connection: The most basic function of a PCB terminal block is to provide a stable electrical connection. It connects various electronic components such as sensors, relays and switches by soldering or plugging them together to ensure that signals and power are reliably transmitted.

Signal Transmission: In circuits where the transmission of signals is critical, PCB terminal blocks effectively support the transmission of signals and, due to their good electrical conductivity, reduce signal attenuation to ensure accurate transmission of information.

Component fixing: In addition to the function of electrical connection, PCB terminal blocks also assume the role of mechanical fixing. It ensures that the circuit components will not be poorly connected due to vibration or movement during the working process, thus improving the stability and reliability of the system.

Simplified Maintenance and Replacement: The PCB terminal block design makes maintenance and replacement of the equipment much simpler. Service personnel can easily remove and replace faulty components without having to perform complex operations on the entire board, reducing maintenance costs and time delays.

Circuit Debugging: During the development and testing phases, the PCB terminal strip can be used as a convenient access point for engineers to debug and test circuits. Through the terminal boards, test instruments can be quickly accessed to the circuit, thus improving debugging efficiency.

Enhanced Thermal Management: Some types of PCB terminal blocks are designed with thermal management in mind. They use thermally conductive materials or are designed with a layout that helps dissipate heat to avoid damage to electronic components due to overheating.

How to choose the right PCB terminal strip

Types of terminals

Different types of PCB terminals are suitable for different application scenarios. Common types of terminals include plug-in terminals, fixed terminal blocks and screwless connectors. When choosing, you need to consider the equipment in the use of the frequency of disassembly needs:

Plug-in terminals: Suitable for applications requiring frequent connection and removal.

Fixed terminals: Suitable for applications requiring long-term fixed connections, e.g. in industrial equipment.

Electrical Characteristics

Understanding and determining the electrical characteristics of the PCB terminal block is an essential part of the selection process. Focus on the following parameters:

Rated voltage and current: Make sure that the terminal block you choose can withstand the rated voltage and current required for the equipment to operate.

Wire cross-section: The diameter of the connected wires should be considered to ensure that the terminal block can be adapted to the required wire size.

Environmental Adaptability

PCB terminal strip operates in a variety of environments, so consider their durability. Select materials that are resistant to high temperatures, humidity, and corrosion to improve the stability of your equipment in harsh environments. These characteristics have a direct impact on the service life of the terminal block.

PCB terminal strip plays a key role in electronic devices across a wide range of industries, with a wide and varied range of applications:

Consumer electronics

PCB terminal strip is an essential component in consumer electronics. They are widely used in mobile phones, tablets, laptops and various other home appliances. Smartphones, for example, use terminal blocks to connect internal components, processors and batteries to support the proper functioning of the device.

Industrial Equipment

PCB terminal blocks are also important in industrial equipment. They are used in a variety of manufacturing machines, automation systems, and control equipment to support the transmission of power and signals to the equipment. These terminal blocks are often designed to withstand high currents and high temperatures to withstand the rigours of industrial environments.

Automotive Systems

The extensive use of electronic components in modern automobiles has made PCB terminal blocks an important part of automotive electronic control units and sensors. These boards are used in navigation systems, in-vehicle media devices and various control systems to ensure the reliable connection and functional operation of electronic components.

Medical Equipment

PCB terminal blocks play a key role in the field of medical equipment. They are used in a wide range of monitoring devices (e.g. heart rate monitors, blood glucose meters) and diagnostic devices (e.g. CT scanners, ultrasound equipment). Due to the high reliability and safety requirements of medical devices, these terminal blocks often need to comply with stringent industry standards.

Aerospace

In aerospace, PCB terminal blocks are used in aircraft, satellites and various communication systems. These terminal blocks must withstand extreme environmental conditions, so high reliability and durability are essential to their design. They are used to guide and control the various systems of the aircraft, ensuring stable operation in harsh environments.

Renewable Energy

PCB terminal blocks play a vital role in renewable energy systems, especially in solar and wind energy equipment. They are used in solar inverters, battery management systems, etc. and are responsible for distributing and regulating current to ensure efficient energy utilisation.

As a core component of electronic equipment connection, PCB terminal strip is widely used in various industries to ensure stable connection of circuits and efficient transmission of signals. When selecting and using them, their type, electrical characteristics and environmental adaptability should be considered according to specific application scenarios.