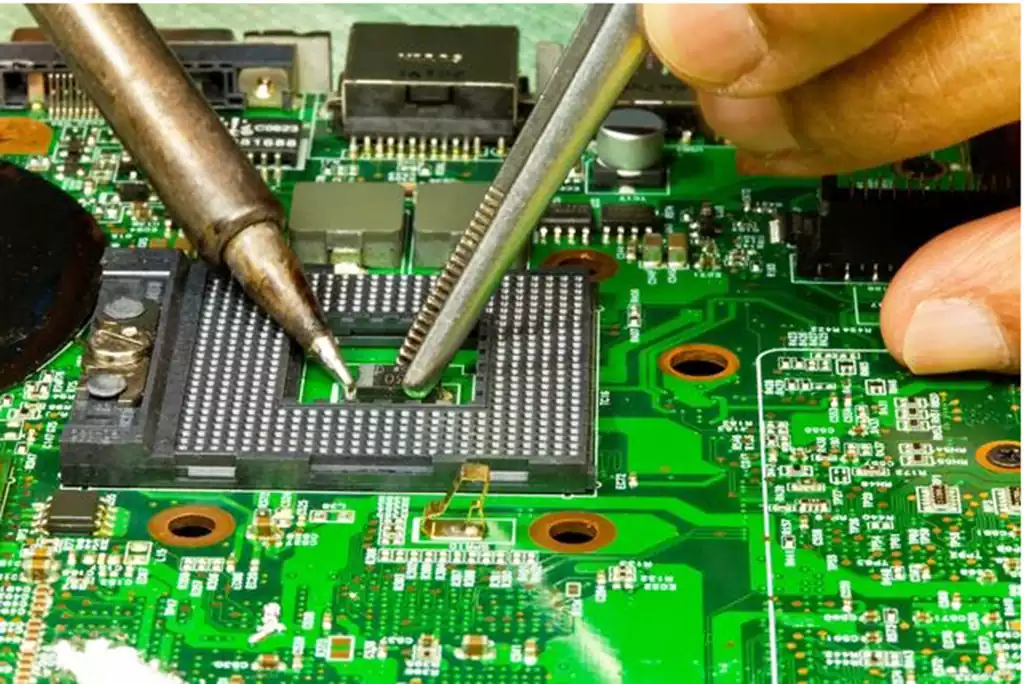

Whether it is the production or removal and replacement time, will be left on the circuit board some of the solder left behind the slag, to clean up these slag will not affect the use of the circuit board. So how to remove solder from circuit board?

The first:Clean up the circuit board on the solder method:

- First shake off the soldering iron on the solder, melt the solder joints again. Repeat a few times to become.

- Find a small section of multi-stranded wire, eat rosin, and solder together with the melt while hot to draw off the wire, can be excess solder to go.

- If a large area of solder, available special hot air gun or tin furnace.

The second: cleaning excess solder slag after welding

- With anhydrous ethanol (or more than 95% alcohol), too dirty to brush with a soft brush dipped in alcohol.

- Subsequently, use degreasing cotton to absorb the dry.

- Use a tin sucker, double-sided board trouble, soldering holes with a hospital needle, soldering iron heated and inserted into the rotation. Or just take a piece of floral wire (soft wire) and bring it up when it melts.

- There is no tin sucker, you can quickly shake the printing plate after heating to shake off the slag, to pay attention to safety, do not move too much. Soldering iron welding, remove the soldering iron head excess solder can shake off the tin.

The third: ultrasonic cleaning method

First soak the circuit board with acetone solution for about 10 minutes or so, and then take out the pcb circuit board immersed in a container filled with anhydrous ethanol. Then drop the container into the ultrasonic cleaning tank, ultrasonic power of 240W, continuous cleaning for about 5 minutes. After the completion of the cleaning can be taken out of the drying.

Residual solder problem will lead to what?

Conductivity problems:

Residual solder may form conductive pathways that lead to poor electrical connections. This can lead to circuit instability, signal interference, and even electrical failures.

Short Circuits:

Residual solder on a circuit board can lead to unwanted short circuits because solder is usually electrically conductive. Short circuits can lead to equipment failure, damage, or overheating.

Degraded insulation:

Unremoved residual solder may degrade the insulation properties of electronic components, which is unacceptable for some applications, especially in high frequency circuits.

Signal Distortion:

In high-frequency or high-precision circuits, residual solder may cause signal distortion, affecting the performance and accuracy of the device.

Reduced Reliability:

Residual solder can lead to a reduction in the mechanical strength of the solder joint, which can reduce the reliability of electronic assemblies. This can lead to broken solder joints or other mechanical failures over the life of the device.

Environmental Impact:

Some solder may contain hazardous substances, such as lead, and residual solder may have a negative impact on the environment. This is a concern for environmental regulations in some areas.

Losses during manufacturing:

In manufacturing, the discovery of a residual solder problem may require additional cost and time to repair, potentially resulting in a loss of productivity.

The removal of residual solder from circuit boards is critical, both for the proper functioning of the board and for productivity and environmental protection. By choosing the appropriate cleaning method, such as using a hot air gun, solder suction or ultrasonic cleaning, you can ensure that the circuit boards are clean and free of residue, which will improve the stability and reliability of the circuit boards, minimize losses in the production process, and also comply with the requirements of environmental regulations. Therefore, when producing or removing and replacing circuit boards, it is important to pay attention to timely cleaning of solder slag to ensure optimal performance and long-term stable use of circuit boards.