The Impact of PCB Impedance Control on Circuit Performance and Stability. In the design of high-frequency, high-speed electronic products, the stability and reliability of circuit performance critically influence product quality. PCB impedance control, as one of the key factors affecting signal transmission quality, is an indispensable technique in high-quality circuit board design.

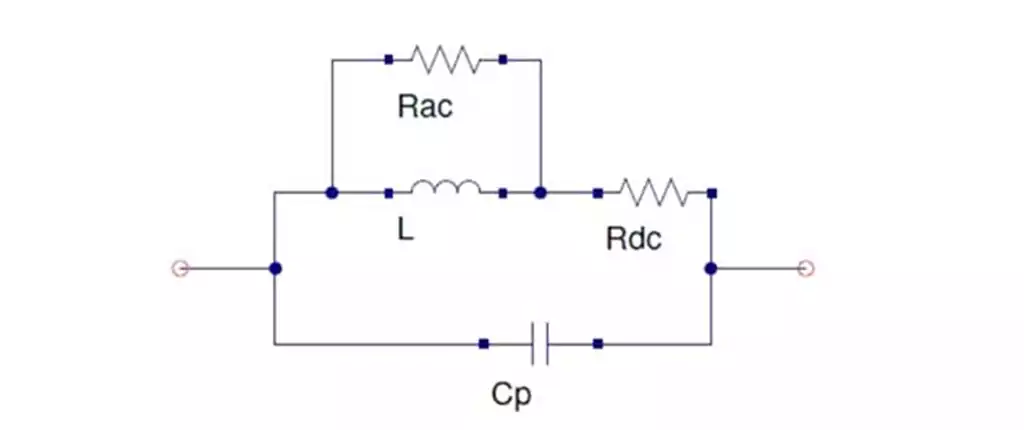

PCB impedance control refers to the process of regulating the characteristic impedance of transmission lines during circuit board design by adjusting parameters such as routing and materials, thereby ensuring signal integrity. Characteristic impedance denotes the resistance value measured under ideal conditions with no reflections as signals propagate along a transmission line, typically expressed in ohms (Ω). For instance, in high-speed signal transmission, the stability of impedance values is paramount for the complete and accurate transmission of signals. Characteristic impedance control, in essence, ensures each signal trace on the PCB achieves its intended impedance value.

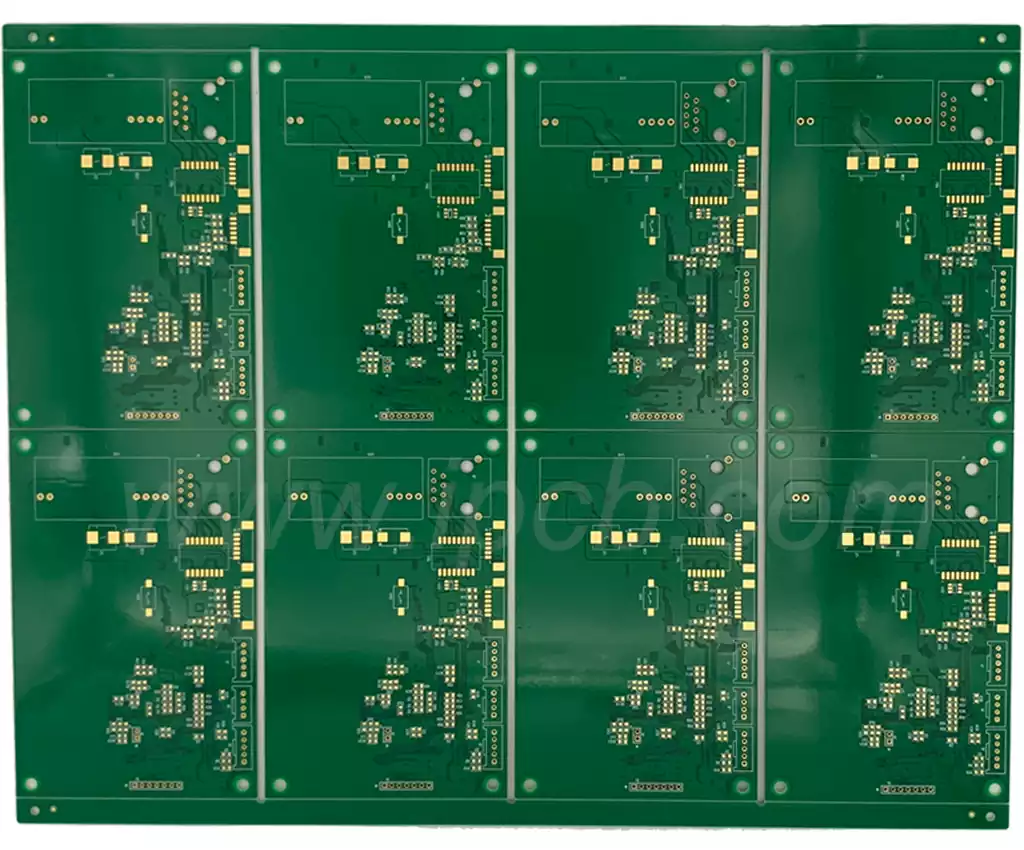

Methods for achieving impedance control are diverse, including adjusting trace widths, modifying copper foil thickness, setting dielectric layer thicknesses, and carefully selecting substrate materials. For multilayer board designs, particularly those involving complex packaging forms such as blind vias, buried vias, and BGA packages, impedance control presents greater challenges, necessitating more precise calculations and process control.

PCB impedance control is paramount for ensuring signal integrity. When the impedance along the transmission path mismatches that of the signal source or load, signal reflections occur, leading to waveform distortion or even data loss. By precisely controlling the PCB’s impedance, these reflections can be minimised, guaranteeing that signals are transmitted clearly and completely from one end to the other. This is particularly critical for applications involving high-frequency circuits, clock signals, and high-speed data transmission.

Moreover, impedance control significantly enhances a printed circuit board’s resistance to interference. Within digital circuits, rapidly changing signals that are not properly managed can cause instability in transmission line impedance, leading to noise and interference that disrupts the normal operation of adjacent components. By precisely managing impedance, the circuit board effectively suppresses such unwanted electromagnetic interference, thereby improving the overall stability and reliability of the system.

The significance of PCB impedance control is particularly pronounced in high-speed applications demanding stringent transmission rates, such as 5G communication equipment and high-speed interconnects within data centres. Inadequate impedance matching causes severe attenuation and energy loss during high-speed signal transmission, substantially reducing transmission efficiency. Sophisticated impedance control techniques can markedly reduce these losses, ensuring signals are transmitted with maximum efficiency and minimal attenuation, thereby safeguarding the performance of high-speed communications.

To design a PCB with controlled impedance, you may follow these routing strategies:

- Identify signals requiring impedance control

During the initial PCB design phase, electrical engineers typically specify which signal networks require specific controlled impedance. Where no explicit instructions exist, designers should consult the integrated circuit’s data sheet to determine which signals necessitate impedance control. Data sheets usually contain detailed guidelines for each signal group and its impedance values, and may provide information on spacing rules and specific signal routing layers. Examples of signals requiring controlled impedance include DDR traces, HDMI traces, Gigabit Ethernet traces, and RF signals. - Clearly specify impedance requirements in the schematic

The circuit board design begins with the design engineer drawing the circuit schematic. At this stage, the engineer must clearly specify signals requiring controlled impedance within the schematic, categorising them as differential pairs (e.g., 100Ω, 90Ω, or 85Ω) or single-ended networks (e.g., 40Ω, 50Ω, 55Ω, 60Ω, or 75Ω). It is good design practice to append polarity indicators N or P after the network names of differential pair signals in the schematic. Should specific controlled impedance layout design guidelines exist, engineers should also note these within the schematic or separate documentation for layout designers to follow. - Determining PCB Controlled Impedance Trace Parameters

PCB trace impedance is determined by its thickness, height, width, and the dielectric constant (Er) of the PCB material. Close attention to these parameters is essential when designing controlled impedance PCBs. You may provide the manufacturer with the number of layers, the impedance values for traces on specific layers (e.g., Layer 3 at 50Ω, 100Ω), and the PCB design materials. Based on this information, the manufacturer will provide a laminate proposal detailing trace widths per layer, layer count, thickness of each dielectric in the stack-up, trace thickness, and PCB material specifications. They will also perform calculations to address controlled impedance requirements, determining feasible trace thickness, width, and height. The fundamental relationship between impedance and dimensions is as follows: impedance is inversely proportional to trace width and thickness, directly proportional to laminate height, and inversely proportional to the square root of the laminate’s dielectric constant (Er). - Distinguishing Controlled Impedance Traces from Other Traces

Controlled impedance traces must be visually differentiated from other traces on the board. This facilitates rapid identification by PCB manufacturers and enables appropriate trace width adjustments to achieve specific impedance targets when necessary. For instance, if a 5mil trace is required to achieve 50Ω impedance and the board also contains other 5mil traces for standard signals, the PCB manufacturer may struggle to differentiate them. Therefore, it is advisable to set the width of the 50Ω impedance trace to 5.1mil or 4.9mil for clear identification. - Maintain symmetry in differential pair routing

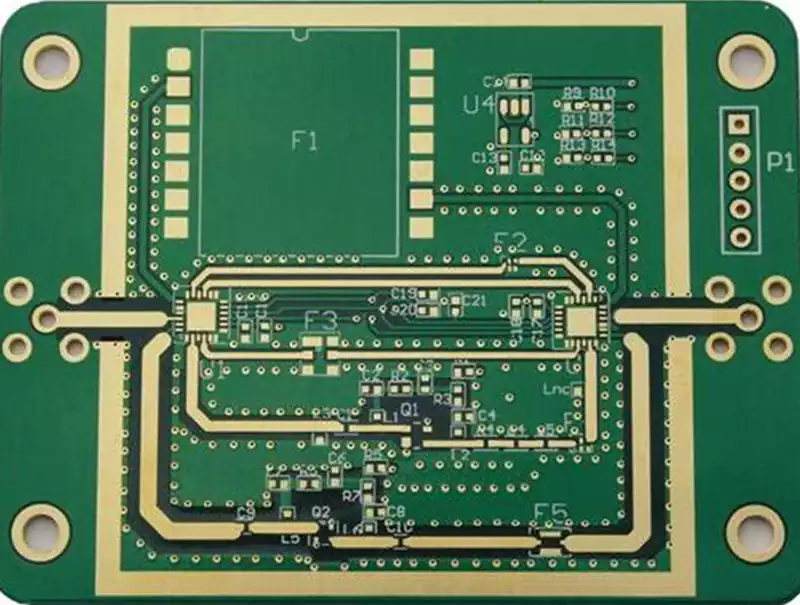

High-speed differential pair signals require parallel routing with constant spacing. Specific trace widths and spacings are necessary to achieve defined differential impedance. Differential pair routing must be symmetrical. Minimise areas where spacing widens due to pads or terminations. - Ensure adequate spacing between controlled impedance traces and other traces/components

To minimise crosstalk, spacing between non-impedance-controlled traces should be at least 3W (three times the trace width) or at least 2W. Note this rule does not apply to spacing between differential pairs. - Reasonable placement of components, vias, and coupling capacitors

Components or vias should not be placed between differential pairs, even if signals are routed symmetrically around them, as these elements cause impedance discontinuities and may lead to signal integrity issues. For high-speed signals, the spacing between one differential pair and an adjacent differential pair should not be less than five times the trace width (5W). A minimum clearance of 30 mils should also be maintained from any other signals. For clock or periodic signals, this distance should be increased to 50 mils to ensure adequate isolation. Should high-speed differential pairs require series coupling capacitors, these must be placed symmetrically to minimise impedance discontinuities caused by capacitance.

By rigorously adhering to PCB design and routing strategies, engineers can effectively manage PCB impedance control, thereby significantly enhancing the performance, stability, and reliability of high-speed electronic products. PCB impedance control is fundamental to ensuring product quality and achieving success in complex electronic designs.