Lead is a chemical element with an atomic number of 82 and an atomic weight of 207.2 u. Lead is a heavy metal that is denser than most common materials. It is a soft, malleable metal with a low melting point. Freshly cut lead is a bluish silver, but it loses its luster and turns dark gray when exposed to air. Lead is the stable element with the highest atomic number, and its three stable isotopes are the termini of the major decay chains of heavier elements. The melting point of lead is 327.502°C, the boiling point is 1740°C, the density is 11.3437 g/cm, the hardness is 1.5, the texture is soft, and the tensile strength is small.

The chemical properties of lead are relatively stable, and it has six excellent properties: First, it has a low melting point and a high specific gravity. It volatilizes significantly at 500~550℃ and is toxic. Therefore, during the mineral processing and smelting process, safety and dust prevention measures should be strengthened and volatilization should be minimized to prevent lead poisoning. Second, it has good corrosion resistance and can be used at room temperature. Lead will not undergo any change in completely dry air. In humid and carbon dioxide-containing air, lead is oxidized, but the surface is covered by a dense lead oxide film to prevent further oxidation inside; at room temperature, lead is almost insoluble in In dilute hydrochloric acid and sulfuric acid (but soluble in nitric acid), and has good corrosion resistance to alkali, ammonia, cyanic acid and organic salts, it is an excellent material for manufacturing acid and alkali-resistant equipment linings and structural parts; third, heat and electricity It is a poor conductor, with thermal conductivity and electrical conductivity of 8.5% and 10.7% of silver respectively; fourth, it can form alloys with many other metals, and is an essential excellent metal material for refining wear-resistant alloys, high melting point alloys, etc.; fifth, it can form alloys with many other metals. It has good ductility and can be pressed into lead sheet or hammered into lead foil, but its ductility is very small and cannot be drawn into lead wire. Sixth, it can absorb radioactive rays and is one of the excellent materials for radiation protection in atomic energy, aerospace, and military industries. Therefore, lead is widely used in electrical, chemical, machinery manufacturing, printing, rubber, glass, ceramics, national defense, atomic energy, aerospace and other industries.

In the electrical industry, lead is widely used in the manufacture of batteries, cable sheaths, and fuses; in the chemical industry, lead plates and lead pipes are widely used in equipment parts, linings, and pipes in the acid-making industry; in metallurgy and nonferrous metals In industry, lead plates are used to make structural parts of wear-resistant and acid-resistant equipment; in the national defense industry, lead and its alloys are used to make warheads, shrapnel projectiles, radioactive protective clothing, caps and facilities; in the atomic energy and aerospace industries, Lead plates are used to make containers and protective equipment for radioactive materials (uranium, thorium) to protect the human body from radioactive rays; various alloys of lead and tin, copper, antimony and other metals are used to cast printing type. Manufacturing bearings, structural parts of wear-resistant and acid-resistant equipment, fusible lead welding rods, etc.

Lead compounds are used in the manufacture of various pigments and have excellent ability to protect colored surfaces from erosion. They are also widely used as colorants in paint, glass, ceramics, chemical fiber industries and hardeners in the rubber industry. Lead acetate is used in medicine and as a mordant in the textile industry. Lead oxide is used as an accelerator in the rubber vulcanization process and in refining petroleum. Tetraethyl lead is added to gasoline to prevent it from exploding when it burns in a car engine. Lead-coated vinyl films are used as sound-absorbing materials in metal workshops and other mechanical processing plants. Lead powder is mixed with vinyl and then woven into fiberglass or other fiber braids, which can reduce noise levels from 95 to 97 decibels to 8 to 8~ 14 decibels.

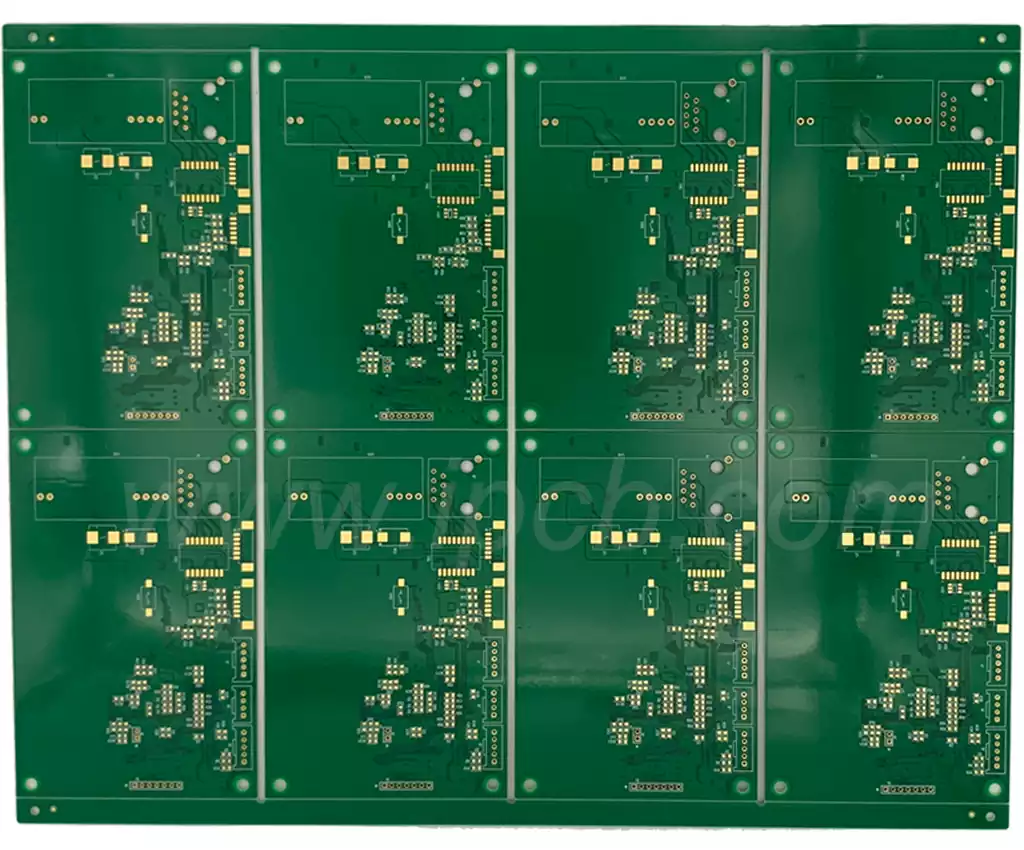

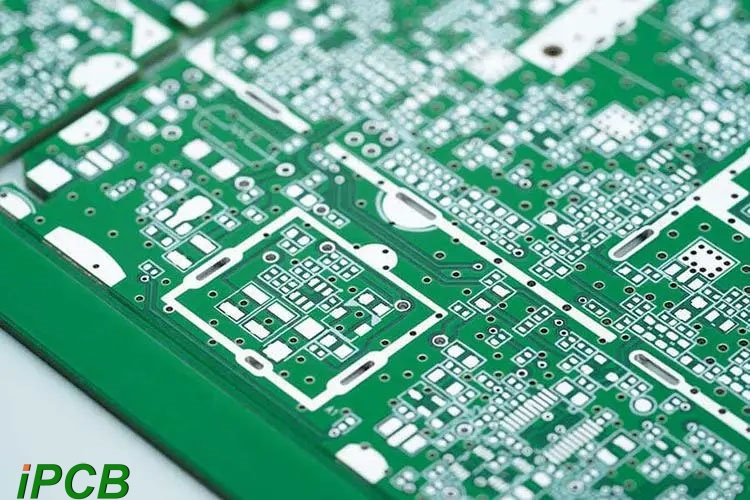

PCB is a circuit board commonly used in electronic components. Its surface usually needs to be welded to connect the electronic components and the circuit board together. When soldering, you need to use a technique called “spray tin”, where solder is sprayed on the circuit board, and then a heat gun or other heating device is used to melt the solder so that it bonds to the surface of the circuit board. In the tin spray technology, there are two different surface treatment processes: lead tin spray and lead-free tin spray.

What is PCB surface treatment?

PCB surface treatment is a process used in PCB manufacturing to ensure that the PCB is protected from external corrosion and rust. It is applied to the solder pads and bare copper areas of the circuit board. The bare copper areas are exposed to transfer heat away from the board as the PCB temperature rises.

It is used in PCB assembly process when electronic components need to be soldered.

By correctly choosing the type of PCB surface treatment we can ensure strong solder joints. The surface treatment acts as a shield between the circuit board copper and the external environment. It supports the soldering process and extends PCB life.

- Lead spray tin

Leaded tin spraying is a traditional tin spraying process, and the solder used is an alloy containing lead. This alloy has a high melting point and fluidity, which can cover the circuit board surface well and form a strong bond with the circuit board surface. Because lead is a toxic metal, there are certain environmental and health risks associated with tin spraying with lead. In some countries and regions, the use of lead-containing tin spray processes has been banned.

Characteristics of leaded PCB:

- Solderability: Lead-containing solder has a lower melting point, making soldering easier and more stable.Good electrical conductivity: Lead can improve electrical conductivity during the soldering process, helping to ensure a high-quality electrical connection.Heat resistance: The addition of lead can improve the heat resistance of solder joints and connections, and is suitable for applications in some high-temperature environments.

- Lead-free spray tin

Lead-free tin spraying is a new type of tin spraying process, and the solder used does not contain lead and other harmful substances. This alloy has a lower melting point and fluidity, making it better suited to the needs of modern electronics. The lead-free tin spray process not only has better environmental protection and health safety, but also improves welding quality and reliability. Therefore, lead-free tin spraying has become a mainstream process method in modern electronic product manufacturing. The importance of lead-free PCB

Traditional lead-containing PCBs release harmful substances such as lead during production and use, posing serious threats to the environment and human health. Lead can enter the ecosystem through the atmosphere, water and soil, accumulate in organisms, and affect ecological balance. At the same time, long-term exposure to lead-containing substances may also cause diseases in the human nervous system, blood system and other aspects. Therefore, promoting lead-free PCB has become an inevitable choice for the electronics industry to achieve green development. Advantages of environmentally friendly lead-free PCB manufacturers

technological innovation

Environmentally friendly lead-free PCB manufacturers are committed to technological innovation and constantly develop new production processes and materials to ensure product quality and performance. By using advanced lead-free soldering technology, environmentally friendly materials, and strict quality control systems, these manufacturers are able to produce high-quality PCBs that meet international environmental standards.

environmental awareness

As an advocate of environmental protection, lead-free PCB manufacturers integrate environmental protection concepts throughout the entire production process. From the selection of raw materials to the optimization of production processes to the disposal of waste, environmental protection requirements are strictly followed. We actively promote green production methods, reduce energy consumption and pollutant emissions, and contribute to environmental protection.

quality assurance

Environmentally friendly lead-free PCBs usually have strict quality control systems to ensure stable and reliable product quality. Through advanced testing equipment and professional quality inspection personnel, each PCB is strictly tested to ensure that the product meets international standards and customer requirements.

Service advantages

In order to meet the needs of customers, environmentally friendly lead-free PCB manufacturers usually provide a full range of services. Not only can we customize PCBs of various specifications according to customer requirements, we can also provide technical support and after-sales service to help customers solve problems encountered during use.

Development prospects of environmentally friendly lead-free PCB manufacturers

In the future, the global emphasis on environmental protection will continue to increase, which will also cause the market demand for lead-free PCBs to continue to grow. Environmentally friendly lead-free PCB manufacturers will usher in a broader development space. At the same time, it will also encourage manufacturers to continue to increase technological innovation, improve product quality and performance, and actively expand the market to provide more customers with high-quality environmentally friendly lead-free PCB products.

As green pioneers in the electronics industry, environmentally friendly lead-free PCB manufacturers are leading the electronics industry toward a greener and more sustainable future with their technological innovation, environmental awareness, quality assurance and service advantages. The electronics industry will achieve more prosperous development while protecting the environment.

The difference between lead spray tin and lead-free spray tin

Environmental protection

The solder used in the lead spray tin process contains lead and other harmful substances, which will cause environmental pollution. The solder used in the lead-free tin spray process does not contain harmful substances and is more environmentally friendly.

Health and safety

The solder used in the lead spray tin process contains harmful substances such as lead, which is harmful to human health. The solder used in the lead-free tin spray process does not contain harmful substances and is safer for human health.

Welding quality and reliability

The lead-free tin spray process can better adapt to the needs of modern electronic products and has better welding quality and reliability. Although the lead-sprayed tin process can also be used for welding, its welding quality and reliability are relatively low due to limitations of its materials and processes.

Cost

Compared with the lead-based tin spraying process, the lead-free tin spraying process has higher production costs. This is because the materials and technologies used in lead-free tin spraying are relatively advanced and require higher technical and equipment support. However, with the continuous development of technology and the expansion of application scope, the production cost of lead-free tin spraying is gradually decreasing.

Controlling the melting point of lead is crucial when welding PCBs. Leaded tin spraying and lead-free tin spraying are two different spray tin process methods. They are environmentally friendly, health and safety, welding quality and reliability, etc. There are certain differences in aspects. As people pay more and more attention to environmental protection and health, the lead-free tin spray process has become a mainstream process method in the manufacturing of modern electronic products. In future development, the lead-free tin spray process will continue to play an important role, bringing more convenience and advantages to PCB manufacturing.