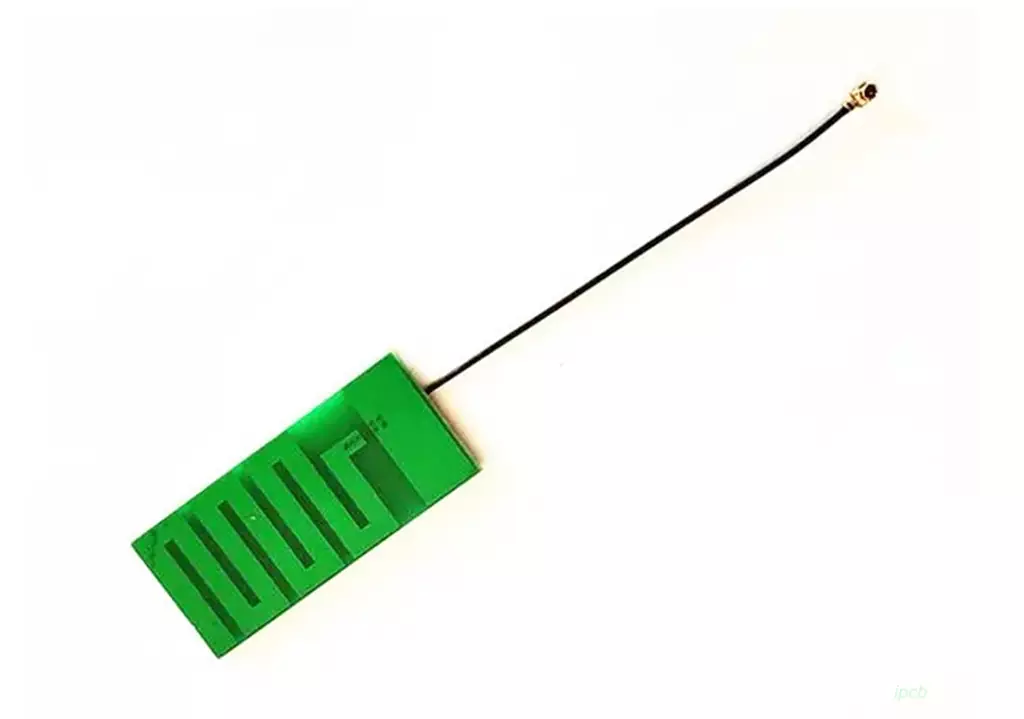

Patches pcb, also known as chip repair technology, is a state in the absence of drawings, to complete the circuit board line detection, component detection, fault diagnosis, repair of professional technology. Circuit board repair is broadly applicable to any equipment board, currently received technology, cost market demand and other factors, circuit board repair mainly refers to advanced products chip-level maintenance, including: touch screen repair, instrumentation repair, servo repair, industrial control machine repair, CMM repair, plastic injection molding machine circuit board repair, embroidery machine circuit board repair, cpu board repair, industrial control products and so on.

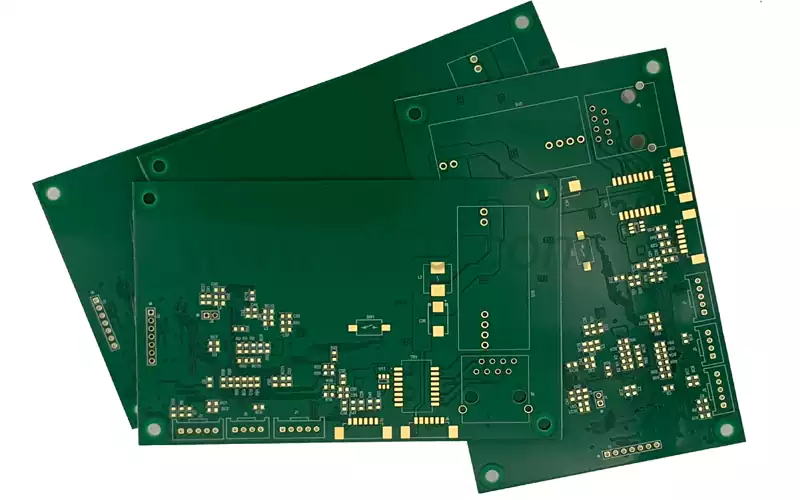

Circuit Board Repair Methods

Soldering repair method

Solder repair method is one of the most common methods of circuit board repair, which uses solder instead of the original wire to connect the broken circuit. It is important to note that when using the solder repair method, you should be careful not to let the solder splash into other circuit paths or cause other damage.

The following methods can be used for repair:

- Use an electronic soldering pencil to patch the solder joint;

- Use soldering wire to patch the solder joints;

- using solder paste to repair the solder joints.

Chemical plating repair method

Chemical plating repair method is an accurate repair of the circuit board on the fine copper circuit of the method, the principle is in need of repair on the circuit board area coated with a layer of chemical paint, and then through the plating method of metal filling into the area. Due to the need to use plating equipment and chemical coatings, this repair method requires a certain level of skill and expertise.

Conductive Adhesive Repair

The conductive adhesive repair method is a simpler repair method that uses a conductive adhesive that is spread over the area to be repaired, allowing for circuit connections to be made. However, because the conductive properties of the conductive adhesive is not as solid as the copper circuit, so you need to avoid the repair method in high-frequency circuits or high-voltage circuits on the use of.

Wire Patch Repair

The wire patch repair method is a method of attaching a wire to the area to be repaired to realize the circuit connection. It is a relatively convenient repair method, but it should be noted that the patch needs to be as close as possible to the connection between the wire and the circuit board and the line, so as not to affect the overall performance of the circuit board.

Line break repair method

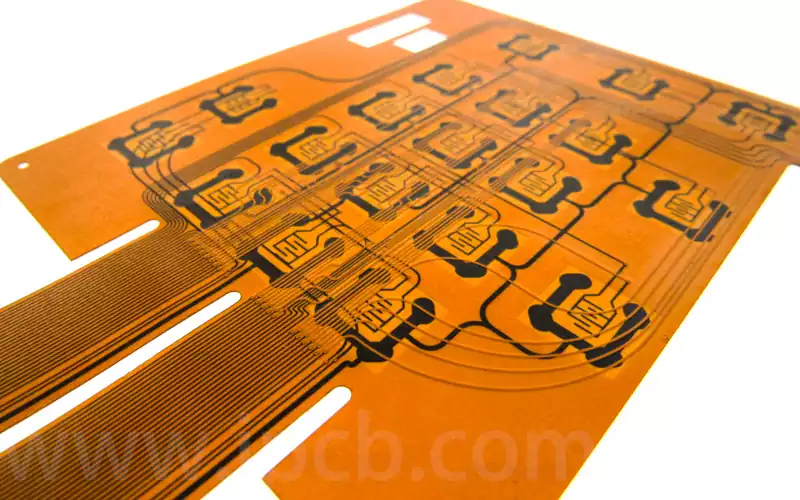

Line breakage is another common problem of circuit boards, circuit boards in the process of use, due to prolonged bending, twisting, etc., resulting in line breakage or open circuit. For this situation, you can generally use the following ways to repair:

- Use conductive glue to re-bond the line;

- Use conductive repair tape to repair the line;

- Use electronic soldering pens to solder the line.

Repair steps

Each patches pcb engineers have their own different judgment methods, repair ideas. But in the repair steps can be summarized in the following six steps. Failure to understand the board repair, the first to understand the fault, the fault judgment will be set in a smaller range, is conducive to the repair work, so it is very important to understand the failure of the circuit board for the start of the repair.

Folding board observation

Board observation is also a preliminary study, the purpose is to understand what input and output interfaces of the board, the board to achieve what functions, the distribution of various control parts of the board and other information.

Folding line test

After completing the fault understanding, board observation, according to the actual situation, the board for the initial testing work, line testing is not necessarily able to find out the board’s fault points, but experienced circuit board repair personnel can be tested to rule out a wide range of faults to pave the way for the next repair.

Folding component detection

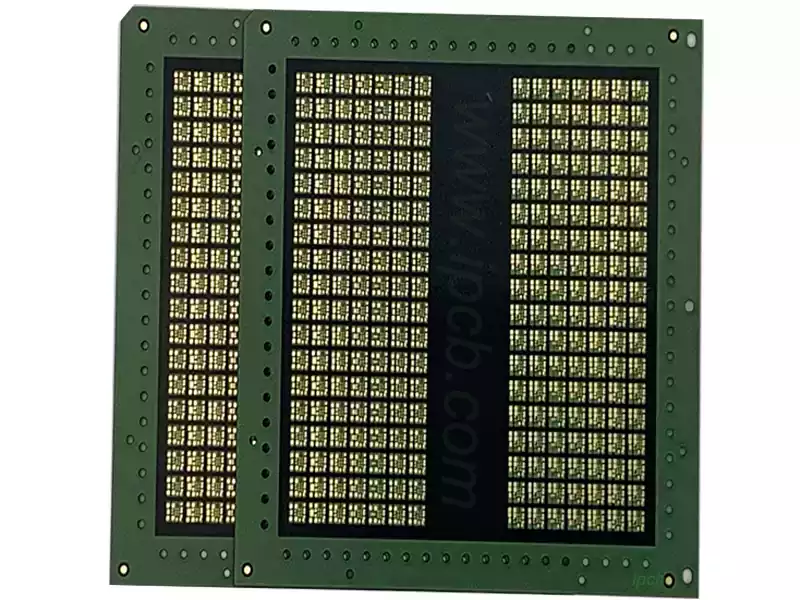

Component inspection, most of the components need to be removed from the circuit board through the soldering iron, and then from the professional equipment testing, the process will cause damage to the external integrity of the circuit board, so in general the maintenance staff will not arbitrarily remove the components.

Folding fault repair

Through line testing, component testing, etc., to find out the fault for processing, including line repair, component replacement, remodeling and other work.

The completed repair work of the board needs to be tested again, to determine the absence of faults, you can test on the machine.

Patches pcb tools, including general tools and professional tools, general tools, including multimeter, wave meter, soldering iron, hot air gun, BGA soldering station, circuit board tester and other tools. The professional tools are based on Huineng circuit board repair tester.