In today’s modern urban landscape, elevators have become an indispensable part of everyday life, particularly in high-rise buildings. From residential towers to commercial skyscrapers, elevators offer convenience, accessibility, and efficiency, making it easier for people to navigate multi-story structures. However, what often goes unnoticed is the critical component that powers the operations of these elevators: the elevator PCB board. Acting as the brain of the elevator system, the printed circuit board (PCB) manages all key functions, ranging from floor selection to safety features, ensuring the elevator runs smoothly and efficiently.

This article will explore the crucial role of the elevator PCB board, including its components, functions, types, common issues, and the importance of maintaining this essential piece of equipment. Elevators are not just transportation devices; they are complex systems that rely on advanced technology to keep them running smoothly, and the PCB board is at the heart of this system.

What is an Elevator PCB Board?

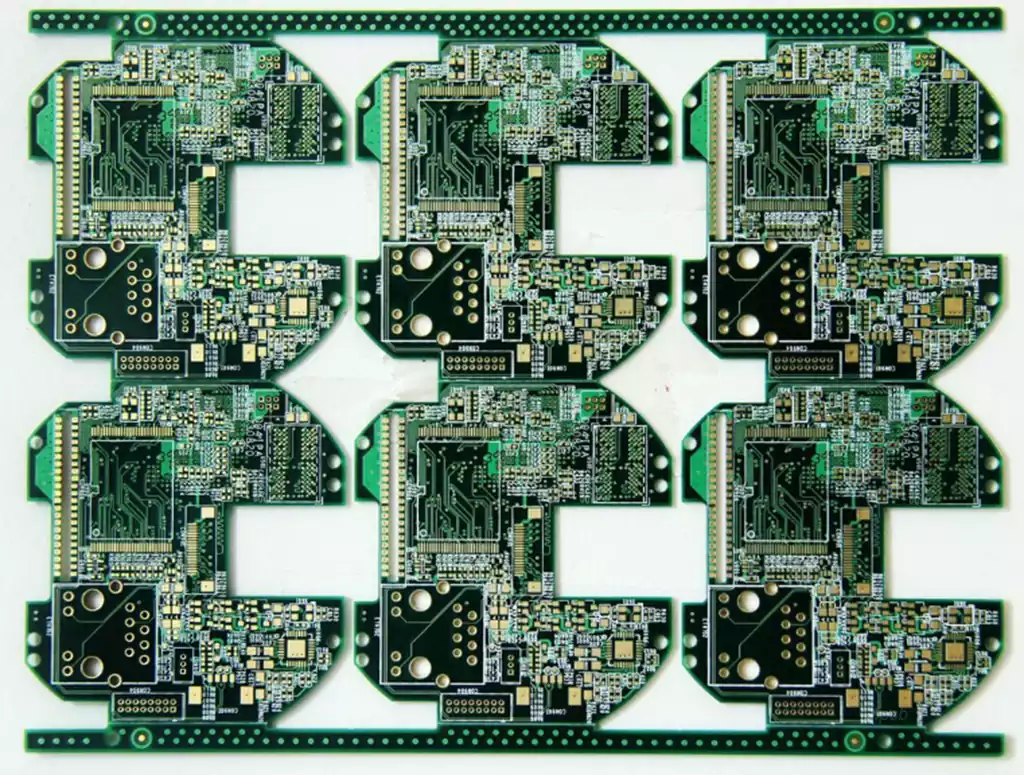

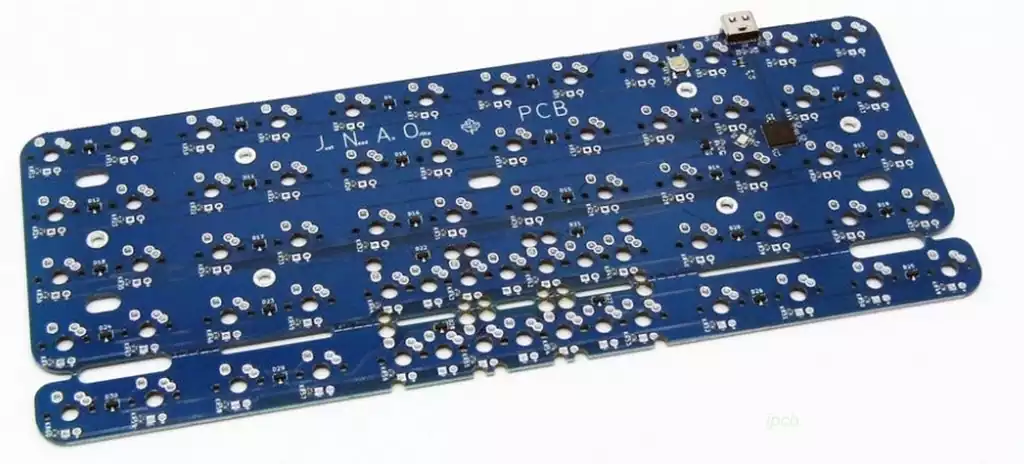

The elevator PCB board is a printed circuit board specifically designed to control the operations of an elevator. The board serves as the central processing unit (CPU) of the system, processing inputs from passengers, sensors, and control panels to execute the elevator’s functions. The elevator PCB board handles everything from controlling the motor that moves the elevator between floors to managing the opening and closing of doors and ensuring safety mechanisms are in place.

Elevator PCB boards come in various configurations depending on the type of elevator system, whether it’s a simple one-stop elevator or a complex, multi-floor high-rise system. In any configuration, the PCB serves as the communication hub, relaying information between different components of the elevator system and executing commands based on that information.

Key Components of an Elevator PCB Board

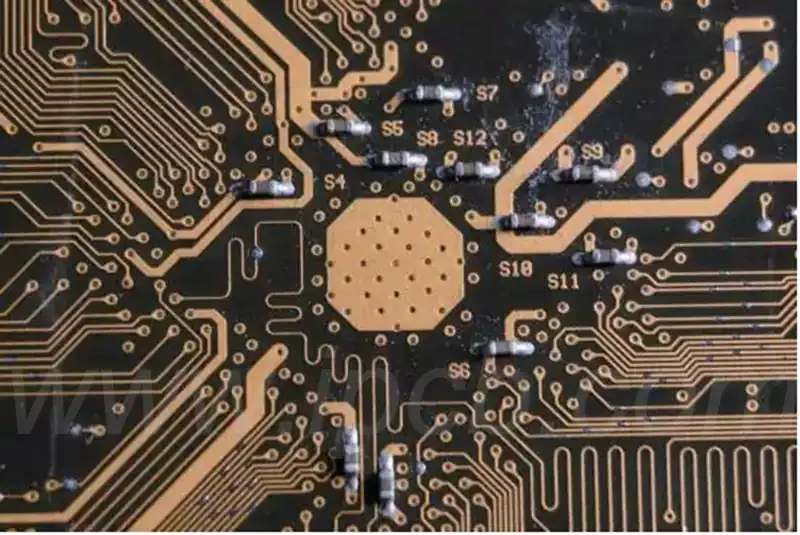

An elevator PCB board consists of various essential components, each serving a specific function. Here are some of the primary elements that make up the board:

- Microcontroller Unit (MCU): The microcontroller is often referred to as the brain of the PCB. It processes signals from different sensors, inputs, and control panels, determining the elevator’s movement and operation. Without an efficient MCU, the elevator system would not be able to function properly.

- Power Supply Unit (PSU): The power supply unit is responsible for converting high-voltage electricity into the appropriate current and voltage for the PCB. Elevators generally require significant power to operate, and the PSU ensures that this power is distributed correctly to the different components of the board.

- Relay Circuits: Relay circuits act as switches that control the flow of electricity within the PCB. These circuits are essential for managing the elevator’s motor, ensuring that it receives the right amount of power to move the elevator between floors safely and efficiently.

- Memory Modules: Memory on the PCB stores critical information about the elevator’s operation, such as floor levels, safety protocols, and movement patterns. This data ensures that the elevator operates consistently and can adjust its functions as needed.

- Input/Output Ports (I/O Ports): These ports allow the PCB to communicate with external devices like elevator control panels, sensors, and displays. The I/O ports act as the gateway for signals to be sent and received, ensuring that all parts of the elevator system work in harmony.

- Sensors and Switches: Elevators rely on various sensors to function correctly, and the PCB processes the data from these sensors. For example, door sensors ensure that the elevator doors do not close while someone is entering or exiting, while weight sensors prevent the elevator from operating if it is overloaded.

- Communication Interfaces: Some modern elevators feature communication interfaces, such as Ethernet or CAN bus, which allow the PCB to connect to building management systems. This enables real-time monitoring of the elevator’s status and allows for remote diagnostics and control.

How Does an Elevator PCB Board Function?

The elevator PCB board functions as the command center of the elevator system. When a passenger presses a button inside the elevator or on a control panel, the board processes this input and determines the appropriate action. For instance, if a passenger selects a specific floor, the PCB board sends signals to the motor to move the elevator to that floor. Once the elevator reaches the correct floor, the board coordinates the opening of the doors to allow passengers to enter or exit.

One of the primary roles of the PCB board is to monitor real-time data from sensors installed throughout the elevator. These sensors provide critical information, such as the position of the elevator, the weight of passengers inside, and whether the doors are closed or open. The board uses this data to make real-time decisions, such as stopping the elevator if an obstruction is detected or slowing down the elevator when it approaches a selected floor.

In more advanced systems, the PCB board works in tandem with software algorithms that optimize elevator movement. This can include traffic management algorithms that reduce waiting times for passengers by efficiently routing the elevator based on current demand and usage patterns.

Types of Elevator PCB Boards

Different types of PCB boards are used in elevators depending on the complexity of the building and the elevator system itself. Here are some common types:

- Basic Elevator Control Boards: These are used in smaller, low-rise buildings with fewer floors. These control boards manage basic elevator functions, such as moving the elevator up and down and controlling the opening and closing of doors.

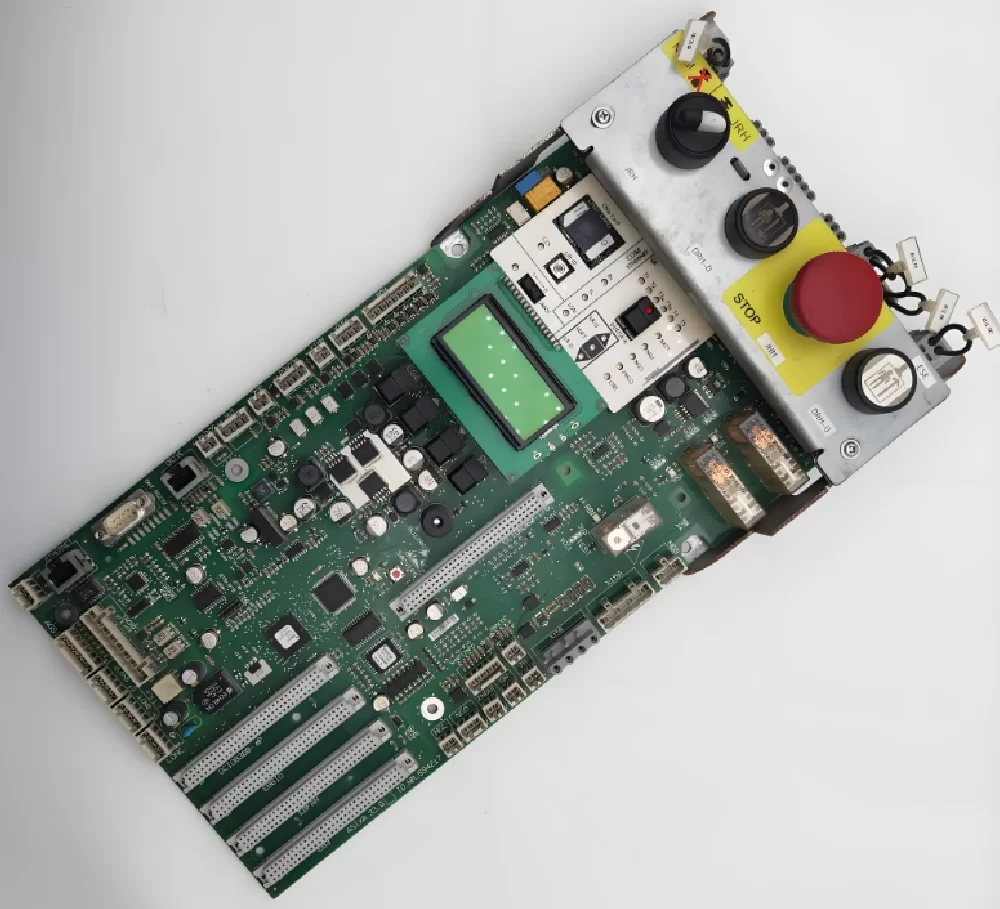

- Advanced Elevator Control Boards: Found in larger, high-rise buildings, these boards are designed to handle more complex operations, including managing multiple elevator shafts, optimizing elevator movement for faster service, and integrating with building management systems for real-time monitoring and diagnostics.

- Safety Control Boards: Elevators must adhere to strict safety regulations, and these control boards ensure that all safety mechanisms function properly. They monitor systems such as emergency brakes, door interlocks, and emergency stop buttons to ensure that the elevator operates safely.

- Communication Boards: In more modern elevator systems, communication boards facilitate communication between the elevator and building management systems. These boards enable remote monitoring, diagnostics, and even software updates to improve elevator performance.

Common Issues with Elevator PCB Boards

Even though elevator PCB boards are designed to be reliable and durable, they can still experience issues due to wear and tear or environmental factors. Some common problems include:

- Component Failure: Over time, the various components on the PCB board can wear out or fail. For example, relay circuits may become damaged, causing the elevator to malfunction. Regular maintenance is essential to identify and replace faulty components before they lead to bigger problems.

- Power Supply Issues: If the power supply unit on the PCB board fails, the entire elevator system can shut down. Power surges, electrical outages, or faulty wiring can all contribute to power supply problems.

- Environmental Damage: Elevators operate in a variety of environments, and factors like temperature, humidity, and dust can impact the performance of the PCB board. Protective coatings and enclosures can help mitigate the risk of environmental damage.

- Software or Firmware Problems: Many modern PCB boards rely on embedded software or firmware to control their functions. Bugs, outdated software, or compatibility issues can lead to erratic behavior, such as missed floor stops or delayed door opening. In such cases, software updates may resolve the issue.

- Wiring and Connectivity Problems: The performance of an elevator PCB board can also be affected by loose connections or broken wiring. This can lead to unreliable communication between the board and other components, causing intermittent malfunctions or complete failure.

Maintenance and Importance of Elevator PCB Boards

Regular maintenance of the elevator PCB board is essential to ensure long-term reliability and performance. Building operators and maintenance teams should inspect the PCB regularly to check for signs of wear, corrosion, or other damage. Replacing worn-out components and performing software updates can help extend the life of the PCB board and keep the elevator functioning efficiently.

Maintaining the PCB board not only ensures the elevator operates smoothly, but it also plays a key role in keeping passengers safe. Elevators are subject to strict safety standards, and any failure in the PCB board can compromise these safety systems. Routine inspections and maintenance are essential to identify potential issues before they lead to safety hazards.

Additionally, given the complexity of modern elevator systems, some PCB boards feature diagnostic functions that can detect potential issues early on. Building management systems may also alert maintenance teams when a problem is detected, allowing them to address it before the elevator system is seriously impacted.

Conclusion

The elevator PCB board is a critical component in modern elevator systems, responsible for processing inputs, controlling movement, and ensuring the safety of passengers. From basic control boards to advanced systems integrated with building management technology, these boards are at the heart of every elevator. Understanding their role, function, and maintenance requirements is crucial for building operators and maintenance teams to keep elevators running safely and efficiently.

By paying close attention to the components, operation, and potential issues associated with elevator PCB boards, facility managers can ensure the longevity and reliability of their elevator systems. As technology continues to advance, these boards will play an even greater role in improving elevator efficiency, safety, and performance.