What is a motor driver board?A motor driver board is a circuit board that is used to control the motor so that it can operate properly. It is an electronic component that controls the motor and is mainly responsible for providing power and regulating the current to drive the motor so that it can operate at a predetermined speed and direction. It acts as a key interface between power transmission and control signals, and its functions include speed control, position control, and overload protection.

There are four major classifications of motor drive boards:

1.DC motor driver pcb is the most commonly used motor driver board, with high speed requirements, it controls the motor through DC motor driver circuit, which can convert DC electrical energy and mechanical electrical energy, and transmit the amplified current to the various structures of the machine to provide energy to the machine, which is mainly used in robots and intelligent remote-controlled carts.

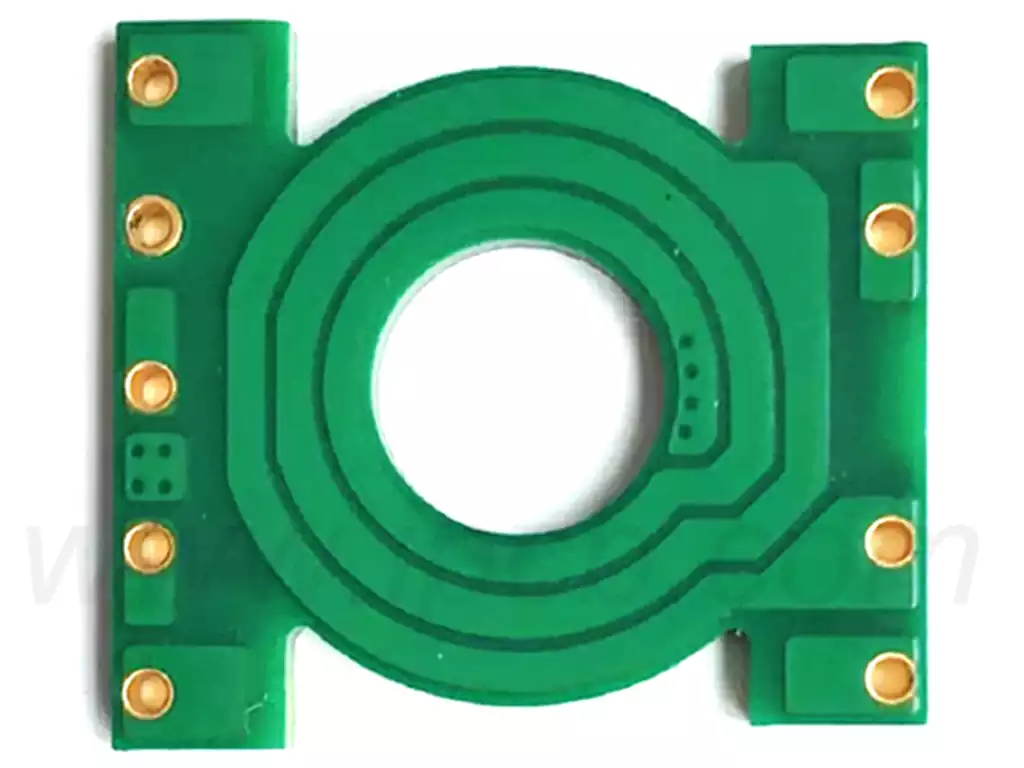

2.Stepping motor drive pcb is to convert the pulse signal into angular displacement or angular velocity, this drive is more complex than the DC motor, by controlling the number of pulses to control the number of angular displacement, can be accurately positioned; control the frequency of pulses and control the speed of motor rotation. It is often used in scenarios that require high control accuracy and reliability, such as engraving machines and 3D printers.

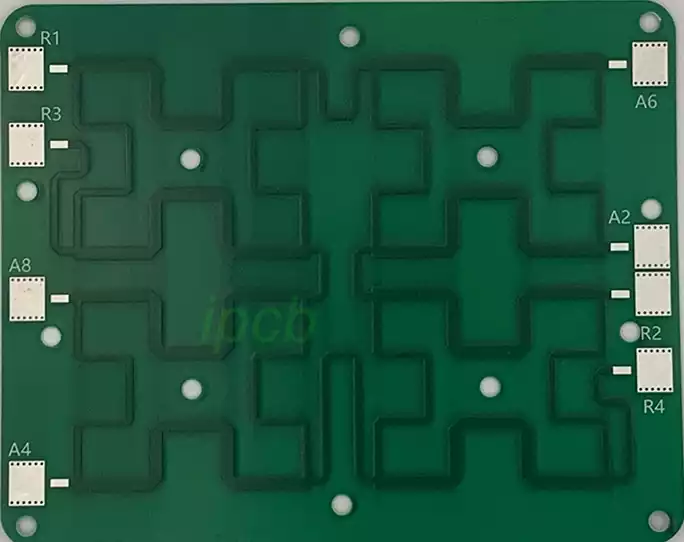

3.Brushless motor driver pcb changes the frequency and waveform of the current to form a magnetic field around the motor, so that the brushless motor rotates through the rotating magnetic field, mainly using electronic speed controller as the driver board, used in aeromodels, aircraft, household appliances and so on.

- Servo motor driver board can convert the signal into torque or speed, so as to drive the motor to drive the gears to rotate, mainly relying on the feedback of the servo motor for position and speed control, high precision accuracy, applicable to robotic arms, processing machinery, handling robots and so on.

The principle of motor drive PCB layout mainly includes the following points:

1.Signal transmission path optimization: For motor drive, signal transmission is crucial. In the PCB layout, crosstalk and interference between signal lines should be avoided as much as possible. You can reduce the impact of electromagnetic interference and improve the stability and reliability of signal transmission by reasonably laying out the signal lines and adopting shielding measures.

2.Power line optimization: motor drive needs to provide stable power supply, so in the PCB layout, the length of the power line should be shortened as much as possible to reduce resistance and inductance. At the same time, for high-power motor drive, you also need to consider the heat dissipation of the power line, reasonable design of the heat sink to maintain the stability of the power supply.

3.Motor circuit layout: the core of the motor drive is the motor circuit, the layout directly affects the performance and stability of the motor. In the PCB design, attention should be paid to the separation of the motor circuit and other parts, using an independent level to avoid mutual interference. At the same time, the heat dissipation of power components should also be taken into account, and the heat dissipation equipment should be reasonably laid out.

Basic principles of motor drive board design

- Determine the motor parameters

Before designing a motor-driven circuit board, you first need to define the power, voltage and current requirements of the motor. These parameters will directly affect the design and performance of the circuit board, including component selection and layout planning. - Layout and wiring design

Reasonable layout and wiring is the key to ensure that the motor drive circuit works properly. The design should reduce the wiring length and electromagnetic interference, while keeping the power, ground and signal lines separated to avoid interference. The motor driver board can be divided into different functional areas to ensure signal integrity and electromagnetic compatibility between the areas. - Power and grounding design

Power supply and grounding design is an important part of the motor drive circuit. A suitable power supply should be selected according to the power requirements of the motor to ensure the stability of the power supply. At the same time, backing up and filtering the power supply can help improve its reliability and stability. - Heat dissipation management

In the motor drive circuit, the heat dissipation problem should not be ignored. The motor driver will generate a lot of heat during operation, so the design needs to choose the appropriate heat sink and thermal conductive materials to ensure that the circuit operates at normal operating temperature. - Electromagnetic compatibility

Motor drive circuit in operation will be affected by electromagnetic interference, the design must consider electromagnetic compatibility. Take appropriate shielding, filtering and other measures can effectively reduce electromagnetic interference, improve the stability and reliability of the system. - Security design

Safety design is crucial to help prevent failures such as overcurrent, overvoltage and short circuit. Protection circuits, fuses and other measures can be used to enhance the safety of the circuit to ensure the stability and reliability of the motor drive.

In pcb motor, the application is very wide, can be a variety of automation control system design and development

- Industrial production line control

In industrial production lines, pcb motors can be used to accomplish a variety of precision control tasks, such as assembly, embossing, measurement, handling and so on. In addition, pcb motors can also be designed into multi-axis control systems for controlling the operation of the entire production line.

2.Robot control

In robotics, pcb motors are also a very important part. Robots can rely on a combination of controllers, sensors, and other technologies to realize a variety of complex movements and operations. For example, robots can use pcb batteries, which are integrated into the motors to control the movement of the robot arm.

- Smart home applications

In the field of smart home applications, pcb motors also have a wide range of applications. For example, they can control the curtains of the smart home, make smart home window openers or automatic door control motors.

In a word,motor drive board, as an effective motor drive technology, will play an important role in the field of industrial robots, home appliances and other automation control. Meanwhile, the future development of pcb motors will face new opportunities and challenges to promote the continuous progress and evolution of motor drive technology.