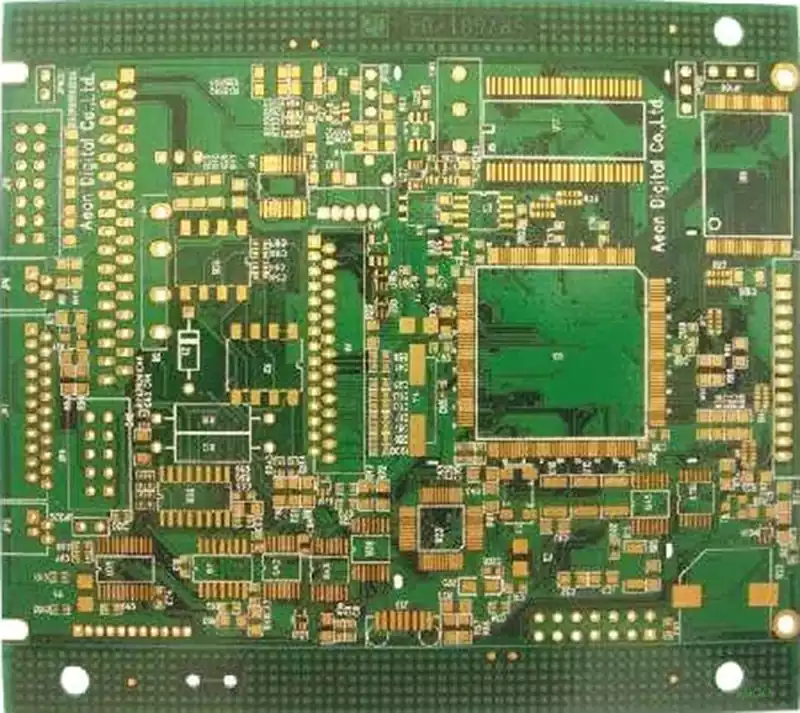

What is fr4 plate?fr4 plate is a commonly used insulating substrate composed of glass fiber and epoxy resin. It has good electrical insulation properties and mechanical strength, and is suitable for the manufacture of electronic circuit boards. Where “fr” is the English abbreviation for “flame retardant”, and fr4 sheet is a material that meets the “fr4” flame retardant rating.

fr4 epoxy fiberglass cloth substrate is a substrate reinforced with electronic grade fiberglass cloth. Its bonding sheet and inner core of thin copper-clad laminate are the primary substrates for the production of multilayer printed circuit boards. Its laminated structure makes it widely used in soldering and printed circuit board (PCB) manufacturing. It has good dimensional stability and temperature resistance and can withstand relatively high temperatures.

Material Properties

It has high insulating properties and can withstand high voltages without conducting electricity.Its insulating properties play an important role in electronic devices,which can effectively isolate various signals and currents in the circuit and improve the stability of electronic equipment.

It has good heat resistance and flame retardancy.This makes it have better stability in high temperature environment, can effectively resist the spread of flame, improve the safety performance of electronic equipment.

Has good mechanical strength and corrosion resistance. It has high strength, can withstand large mechanical stress, and is suitable for all kinds of complex assembly and installation methods.At the same time, it also has good resistance to common solvents and chemicals,not easy to be affected by corrosion.

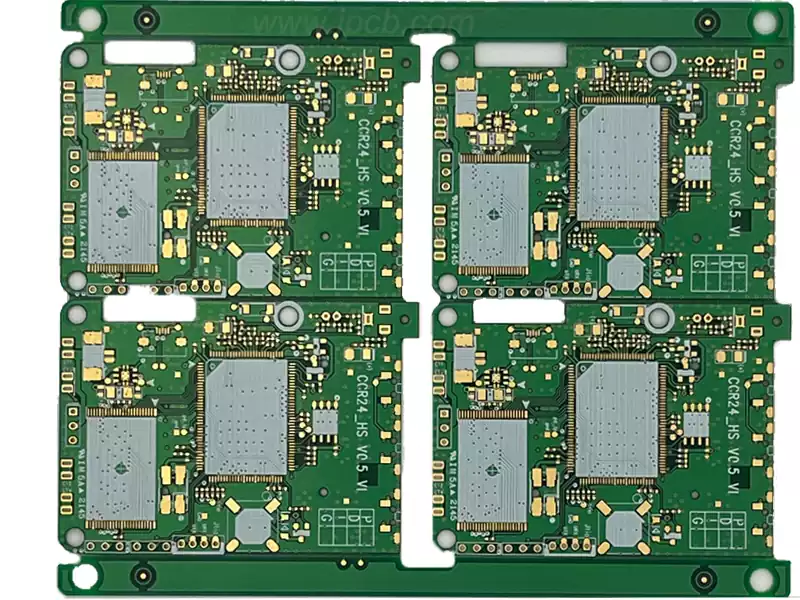

Has excellent electrical properties, for the normal operation of electronic devices to provide a guarantee. fr4 substrate has a low dielectric constant and good impedance stability.This allows it to effectively control the transmission speed and quality of the signal in the design of high frequency circuits and reduce the signal loss in the circuit.The dielectric loss angle tangent of this sheet is small,and the attenuation of signal transmission is small. This is particularly important for high-speed signal transmission electronic equipment, can improve the quality and reliability of signal transmission. Good arc resistance, can withstand high arc energy without breakdown.This is one of the important conditions to ensure the stable operation of electronic equipment for a long time.

Excellent mechanical strength, able to adapt to different stress environments. fr4 substrate has high flexural and tensile strength, able to withstand large mechanical forces.This provides good protection against mechanical vibration and impact during transportation,assembly and use of electronic equipment. It has moderate hardness,which is not easy to crack,but also has a certain degree of toughness,and can withstand a certain degree of impact and pressure to protect the safety of electronic devices.

It has good processing performance,applicable to a variety of processing technology. fr4 substrate is easy to cut into various shapes and sizes, to meet the needs of different electronic devices.It has good cutability and can be processed by tool or laser. High surface flatness makes it easy to form neat soldering joints, which is conducive to the assembly and soldering of electronic components. The surface can be coated with solder paste and solder resist, which is convenient for soldering and protection of electronic components.

Material parameters of fr4 board

The dielectric constant of FR4 material is an important parameter.The dielectric constant determines the material’s ability to respond under the action of an electric field, and is critical to the signal transmission and electromagnetic compatibility of the PCB.Generally,the dielectric constant of FR4 material is around 4.0, which means that it has a moderate responsiveness to electric fields and can meet the requirements of most electronic products.

Secondly, the dielectric loss factor is also one of the parameters to be considered. The dielectric loss factor is an indicator of the material’s energy loss under the action of an electric field, which has an important impact on high-frequency signal transmission and power loss. Generally, FR4 materials have a dielectric loss factor of around 0.02, which means they perform well in high frequency signal transmission and power loss.

In addition to this, the coefficient of thermal expansion is also one of the parameters that need to be understood. The coefficient of thermal expansion determines the dimensional change of the material under temperature change, which has a significant impact on the stability of the PCB in different temperature environments.Generally speaking,the coefficient of thermal expansion of FR4 material is between 13-18ppm/°C,which means that its dimensional change under temperature change is relatively stable.

In addition, the glass transition temperature is a parameter that needs to be understood. The glass transition temperature is the temperature at which the material changes from a glassy state to a polymer flow state during heating, and has an important effect on the thermal stability of the material. Generally speaking, the glass transition temperature of FR4 materials is between 130-140°C, which means that it is more stable in high temperature environments.

Finally, electrical strength is also a parameter that needs to be emphasized. Electrical strength refers to the insulating properties of a material under the action of an electric field, and has a significant impact on the safety of PCBs in high-voltage environments. Generally speaking, the electrical strength of FR4 material is between 16-20kV/mm, which means it can meet the safety requirements of most electronic products.

FR4 boards have a wide range of uses, mainly in electronics, electrical, communications, aerospace and other fields:

- Circuit boards

In electronics manufacturing, this sheet is usually used in the manufacture of circuit boards. It can be used as a substrate material for circuit boards to ensure the stability and reliability of circuit boards. - Spacer and isolation material

It has superb insulating properties and high temperature stability, so it can be used as a spacer and isolation material in electric power systems. This not only ensures the electrical safety of the equipment, but also avoids accidents caused by electrical faults.

3.Mechanical parts

It can be used as the material for mechanical parts, such as machine tool partitions, automobile engine hoods and so on. It has excellent mechanical properties and chemical stability and can be applied in different mechanical systems.

With its excellent electrical insulation properties and mechanical strength, FR4 sheet has a broad application prospect in the electronics industry, and plays an indispensable role in the electronics, electrical, communication and aerospace industries.