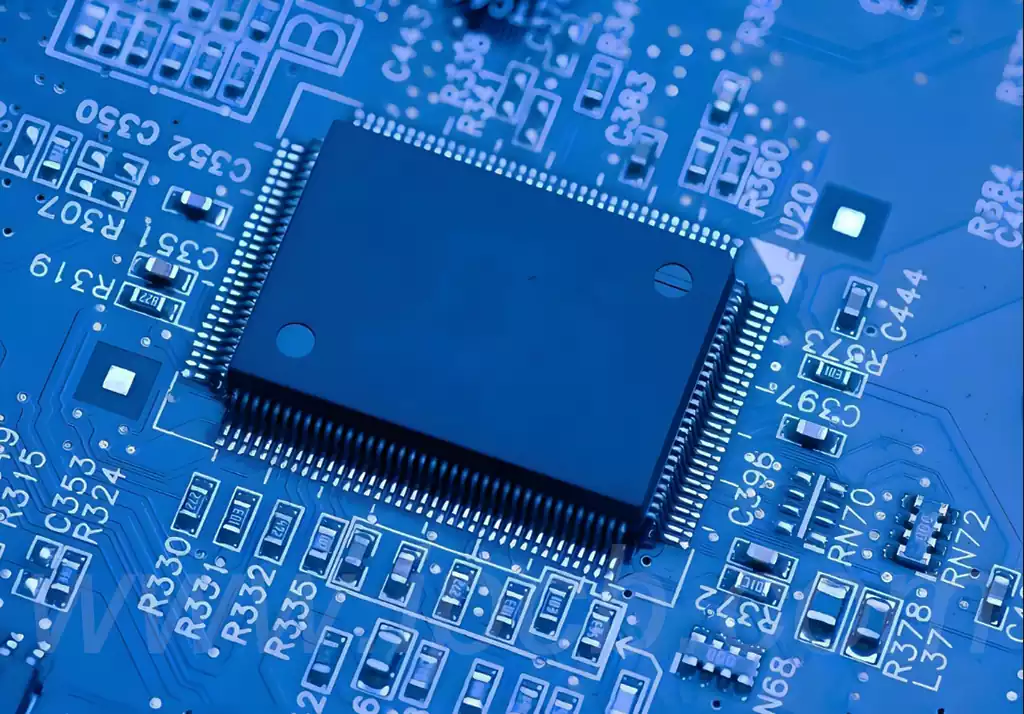

Ceramic circuit boards utilise ceramic as the substrate material, upon which metallic circuits are constructed and conductive vias formed. Ceramics encompass a diverse range of materials, with commonly employed types including aluminium oxide, aluminium nitride, zirconium oxide, silicon carbide, and silicon nitride – all classified as inorganic non-metallic materials. The fabrication of ceramic discs or structural components involves processing powders of these materials into their final form. Ceramics possess numerous excellent properties, enabling them to effectively address various challenges encountered in the electronics industry.

Ceramic discs require firing at temperatures exceeding 1000°C, conferring outstanding high-temperature resistance. Traditional ceramic discs can withstand breakdown voltages as high as 17kV, demonstrating exceptional electrical insulation properties. As inorganic non-metallic materials, they exhibit highly stable chemical behaviour. simultaneously, ceramic materials exhibit remarkably high thermal conductivity parameters. Aluminium oxide (Al₂O₃) thermal conductivity ranges between 17–35 W/m·K, while aluminium nitride (AlN) typically achieves 170–230 W/m·K. Current specifications for commonly used aluminium nitride require thermal conductivity of ≥180 W/m·K. These figures inevitably draw comparisons with metallic thermal conductivities, such as aluminium’s 237 W/m·K and copper’s 397 W/m·K – both notably higher values. However, aluminium and copper are metallic materials and excellent electrical conductors, rendering them unsuitable for direct use in packaging applications. To utilise them, an insulating layer must be applied to their surfaces before wiring operations, significantly diminishing the actual thermal conductivity of aluminium and copper substrates. Consequently, their final thermal conductivity values are reduced to single digits. Thermal conductivity parameters serve as metrics for evaluating a material’s ability to conduct heat; higher values indicate superior thermal performance, fully demonstrating the outstanding thermal properties of ceramic materials.

The electronics industry currently prioritises resolving chip thermal management. Thermal structures demonstrate that addressing heat dissipation directly ensures stable chip operation. Ceramic circuit boards tackle both thermal management and thermal expansion issues. Given silicon’s prevalence as the primary chip material, ceramic’s unique coefficient of thermal expansion closely matches silicon’s properties, making ceramic circuit boards the preferred choice for high-power chip packaging.

As electronic technology deepens across diverse applications, high circuit board integration has become an inevitable trend. High-integration packaging modules demand robust thermal management systems. The thermal conductivity (TC) limitations of traditional FR-4 and CEM-3 circuit boards have emerged as a bottleneck constraining electronic technology advancement. Consequently, the requirements for their component carriers—PCBs—continue to escalate, leading to the emergence of ceramic circuit boards. Ceramic materials exhibit superior high-frequency and electrical properties, coupled with high thermal conductivity, excellent chemical stability, and thermal stability—qualities absent in organic substrates. They represent the ideal packaging material for next-generation large-scale integrated circuits and power electronic modules.

Ceramic circuit boards offer the following significant advantages:

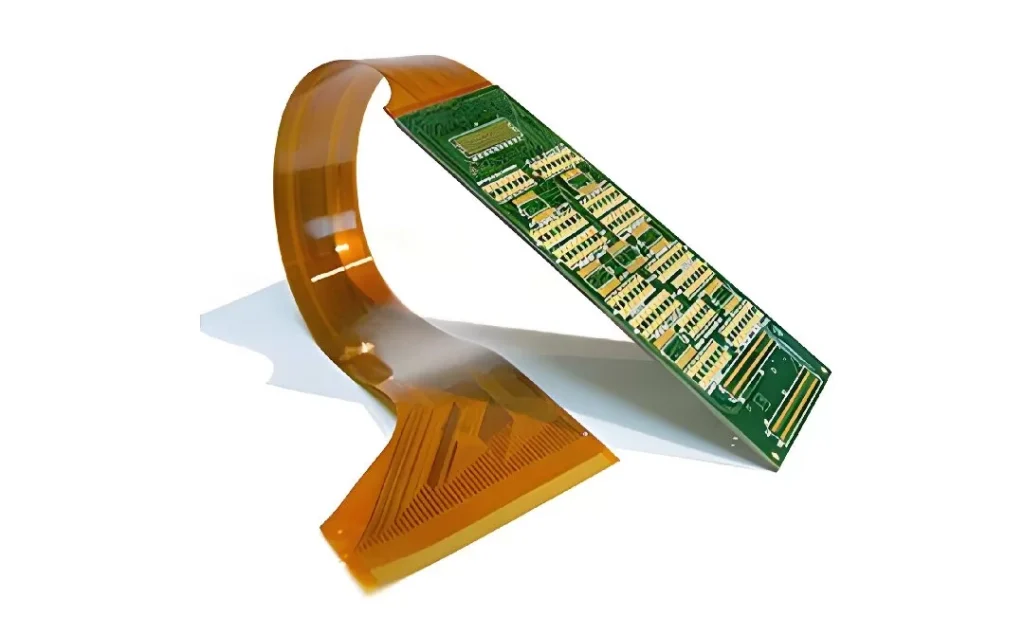

Shape stability with minimal warping:

Conventional PCBs typically comprise copper foil laminated to substrate materials such as fibreglass (FR-4), phenolic resin (FR-3), aluminium-based, copper-based, PTFE, or composite ceramics, bonded with adhesives like phenolic or epoxy resins. During PCB fabrication, factors such as thermal stress, chemical influences, improper manufacturing processes, or asymmetrical copper distribution on both sides can readily cause varying degrees of warping.

Ceramic circuit boards, however, overcome this issue due to the inherent properties of ceramic materials: high hardness, excellent heat dissipation, and a low thermal expansion coefficient. Furthermore, the use of magnetron sputtering ensures a strong, durable bond between the copper and substrate, preventing copper foil detachment and enhancing reliability. This effectively eliminates the warping problems common in standard PCBs.

High current-carrying capacity:

When a 100A current continuously passes through copper bodies of 1mm and 0.3mm thickness, the temperature rise is approximately 17°C. When the same current passes through 2mm and 0.3mm copper bodies, the temperature rise is only about 5°C.

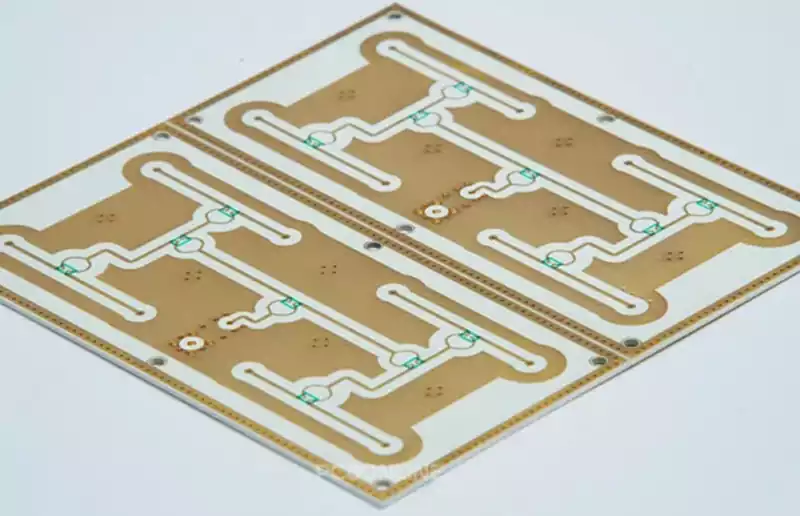

Superior thermal conductivity:

Within ceramic circuit boards, aluminium oxide achieves thermal conductivities of 15–35 W/m·K, while aluminium nitride reaches 170–230 W/m·K. Their thermal expansion coefficients exhibit high compatibility, with tensile strength values tested up to 45 MPa.

High thermal conductivity coefficient:

Thermally conductive aluminium substrates typically exhibit thermal conductivity coefficients between 1–4 W/m·K. Ceramic substrates, however, can achieve coefficients around 220 W/m·K depending on preparation methods and material formulations.

Low thermal resistance:

For a 10×10mm ceramic substrate, the thermal resistance is 0.31K/W at 0.63mm thickness, 0.19K/W at 0.25mm thickness, and 0.19K/W at 0.38mm thickness.

Outstanding Insulation and Voltage Resistance:

Ceramic circuit boards exhibit excellent insulation properties and high voltage resistance, ensuring both personal safety and equipment security. Their strong bonding capability, utilising bonding technology, prevents copper foil detachment, delivering high reliability and stable performance even in high-temperature, high-humidity environments.

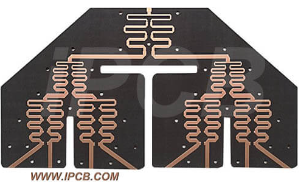

Stable High-Frequency Performance:

Their AK and DK values are lower than PTFE, meeting ceramic-specific requirements and ensuring stable performance in high-frequency applications.

The drilling processes for ceramic circuit boards primarily include the following:

- Mechanical Drilling: A traditional method employing drill bits to physically cut the ceramic substrate to achieve the required hole diameter and depth. Suitable for ceramic materials of varying hardness, though it may induce drilling stresses and thermal damage.

- Laser drilling: Utilises a high-energy laser beam to precisely heat specific areas of the ceramic material, causing evaporation or melting to form the desired aperture. Laser drilling offers high precision, speed, and a minimal heat-affected zone, making it suitable for high-accuracy and complex-shaped drilling requirements.

- Electrical Discharge Drilling: Employing electrical discharge machining technology, this process generates discharges on the ceramic substrate to melt or vaporise material, thereby forming holes. Electrical discharge drilling is suitable for hard ceramic materials, characterised by high machining precision and excellent surface finish.

- Ultrasonic Drilling: Utilises the vibrational energy of ultrasonic waves in conjunction with abrasives to process ceramic substrates for drilling purposes. Ultrasonic drilling minimises thermal damage and mechanical stress, making it suitable for processing brittle materials.

- Horizontal Drilling: This specialised drilling technique employs horizontally oriented drill bits to process ceramic substrates, ideal for hole machining requiring specific angles or positions.

Application Domains of Ceramic Circuit Boards:

- The Ideal Choice for High-Power Electronic Equipment

Owing to their outstanding thermal conductivity and high-temperature resistance, ceramic circuit boards are the preferred choice for high-power electronic equipment. For instance, power modules in electric vehicles must handle substantial currents; traditional materials are prone to failure due to overheating, whereas ceramic boards effectively dissipate heat, ensuring stable operation. Furthermore, power conversion modules within solar inverters widely adopt ceramic circuit boards to enhance energy conversion efficiency. - The unsung hero in high-frequency communications

Within high-frequency communications, ceramic circuit boards’ low dielectric loss and stable signal transmission properties make them a critical material. RF modules in 5G base stations, which handle high-frequency signals, benefit from ceramic boards’ ability to minimise signal attenuation and improve communication quality. Satellite communication equipment likewise relies on ceramic circuit boards to ensure signal reliability in extreme environments. - Reliable Partner in Medical Devices

Medical equipment demands exceptional material stability and safety. Ceramic circuit boards, with their biocompatibility and corrosion resistance, serve as dependable components in medical electronics. For instance, circuit boards within pacemakers require long-term stable operation, and ceramic materials effectively prevent bodily fluid corrosion. Furthermore, medical imaging equipment such as CT scanners utilise ceramic circuit boards to ensure high-precision signal transmission.

Ceramic circuit boards demonstrate outstanding material properties and performance, including high-temperature resistance, excellent thermal conductivity, strong insulation, and stable high-frequency characteristics. Combined with versatile drilling techniques, they adapt to diverse requirements across the electronics industry. As the sector continues its steady advancement, ceramic circuit boards will persistently leverage their inherent qualities to deliver reliable support within established applications.