Wireless charger pcb, as the name suggests, is a circuit board used for wireless charging of mobile phones. It adopts advanced wireless charging technology, which transmits electricity to the mobile phone battery through electromagnetic induction, realising a charging method without plugging and unplugging. This technology is not only convenient and fast, but also effectively avoids wear and tear of the charging interface and extends the service life of the mobile phone.

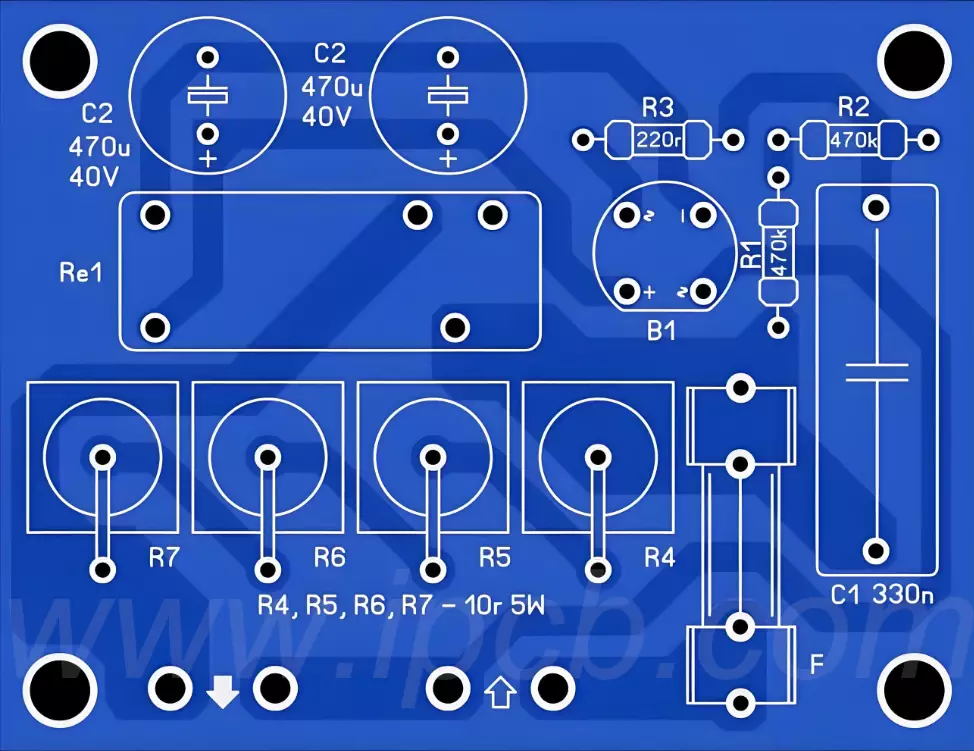

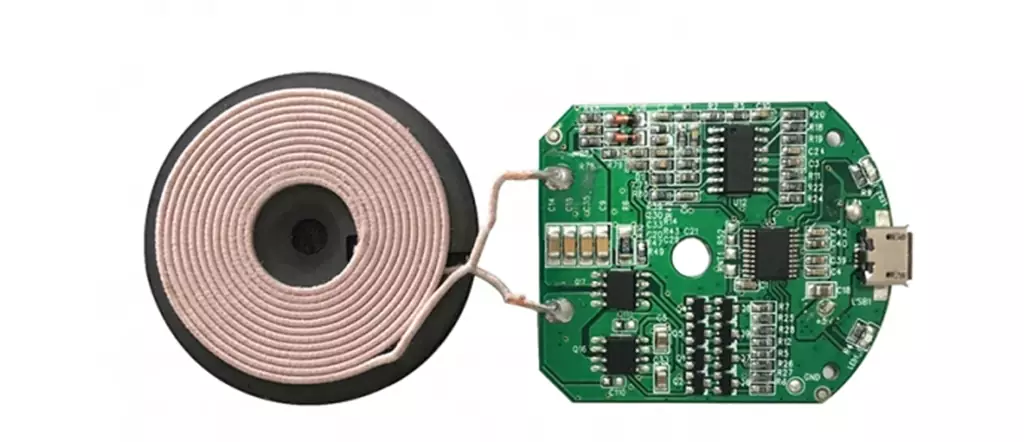

The wireless charger pcb is mainly composed of two parts: the transmitter circuit and the receiver circuit. The transmitter circuit is responsible for converting the input power signal into wireless electromagnetic waves and transmitting them to the receiver circuit. The receiver circuit is responsible for receiving the electromagnetic wave transmitted from the transmitter, and then converting it into DC power through rectifier and converter circuits, and finally outputting it to the battery for charging.

The basic principle of wireless charging is based on electromagnetic induction and the transmission of electromagnetic waves. In a wireless charging system, the transmitting coil in the base of the charger generates an alternating magnetic field through alternating current, and this magnetic field is able to induce a current in the receiving coil of the receiving device, thus realising the charging process. The circuit board plays a crucial role in this process, not only connecting and controlling the transmitting and receiving coils, but also responsible for signal conversion and voltage adjustment to ensure the stability and safety of charging. Common wireless charger pcb includes capacitive wireless charger. Magnetic resonance wireless charger. RF wireless charger. Among them, capacitive wireless chargers are convenient to implement, but the charging efficiency is low, suitable for low power applications. Magnetic resonance wireless charger relative to capacitive wireless charger power is higher, charging efficiency is higher, but the installation configuration is more complex, and can charge the distance is limited. RF wireless charger is the emerging wireless charger technology in recent years, can achieve long-distance wireless charging, but also need the corresponding high-frequency power supply equipment support.

Chips needed for wireless charger pcb:

Power Management IC

One of the core components of the wireless charger pcb is the power management IC, which is mainly responsible for the overall management of the power supply. The IC can precisely regulate the charging current and voltage to ensure the safety and stability of the charging process. At the same time, it can also intelligently adjust the output power according to the charging progress of the device, effectively preventing the battery from being damaged due to overcharging or undercharging.

Magnetic field generation and control chip

The magnetic field generation and control chip is an indispensable key component of the wireless charger pcb,whose main responsibility is to stimulate the magnetic field and monitor the operating mode of the electromagnetic coil. It generates a stable or adjustable magnetic field based on the control commands it receives to drive the electromagnetic coil. It also integrates short-circuit and overheat protection mechanisms to ensure the safety and reliability of the charging process.

Receiver Module Chip

The receiver module chip focuses on capturing signals from the electromagnetic coil and converting them into precise control commands for charging the mobile phone. The chip needs to be highly sensitive and accurate to ensure that the charger can accurately sense and respond to the charging status of the device. It also incorporates an anti-touch design that effectively prevents accidental charging caused by poor contact between the charger and the mobile phone.

Communication Bridge Chip

In order to achieve smooth communication between the wireless charger pcb and mobile phones and other devices, the communication bridge chip plays a crucial role. This chip converts the signals generated by the charger circuit board into a data format that can be interpreted by the mobile phone, and converts the control commands sent by the mobile phone into a language that can be understood by the charger circuit board. Common types of communication bridge chips include I2C, SPI, and UART.

Wireless charger pcb is used in a wide range of industries covering consumer electronics. Automotive electronics. Smart Home. Medical equipment and industrial and other categories:

Consumer Electronics

1.Smartphones and tablets: This is the most common application scenario for wireless charger circuit boards. Users can simply place their mobile phones or tablets on the wireless charging board to enjoy a cable-free charging experience, and this convenience makes wireless charging popular in the consumer market.

2.Wearable equipment: such as smart watches. Wearable devices such as wireless headphones also have wireless charging capabilities. These devices are frequently used despite their limited battery capacity, and the convenience of wireless charging plays a key role in optimising the user experience.

Automotive Electronics

1.Wireless charging for electric vehicles: Wireless charging technology for electric vehicles is becoming increasingly mature and commercially available. The wireless charging system consists of a transmitter (installed on the ground or in a parking space) and a receiver (installed at the bottom of the EV). When the electric car is parked in the charging area, the electromagnetic induction principle is used to realise the wireless transmission of electric energy. This technology reduces the physical contact in the charging process and improves the convenience and safety of charging.

2.In-vehicle wireless chargers: Many automotive circuit board manufacturers have integrated wireless chargers in their vehicles, making it easy for drivers and passengers to charge their mobile phones and other devices. This design not only enhances the sense of technology in the vehicle, but also avoids the problem of cable chaos caused by traditional wired charging.

Smart Home

1.Wireless charging for smart home devices: In the field of smart home,wireless charging technology is also widely used in various types of smart devices. For example, smart speakers. Smart door locks and other devices can be charged with wireless charging boards, without the need to frequently replace the battery or plug and unplug the charging cable.

2.Furniture and wireless charging integration: some high-end furniture such as coffee tables. Bedside tables, etc. into the wireless charging function,users only need to place mobile phones and other devices on the furniture can be charged,this design not only improves the practicality of the furniture,but also adds to the convenience of home life.

Medical equipment field

1.Wireless charging of medical instruments: In the field of medical equipment,wireless charging technology is applied to the charging of various portable medical instruments. For example, electrocardiograph.Blood glucose meter and other equipment can be charged by wireless charging board,avoiding the risk of cross-infection that may be caused by traditional wired charging.

2.Wireless charging of medical robots: such as surgical robots.Medical robots,such as surgical robots and nursing robots,also use wireless charging technology, which eliminates the need for robots to return to the charging station frequently when carrying out their tasks and improves work efficiency and safety.

Industrial Scope

1.Wireless charging for industrial equipment: In the industrial field, wireless charging technology is used in the charging of various industrial equipment. For example, robots in automated production lines. Drones and other equipment can be charged by wireless charging boards, reducing manual intervention and downtime.

2.Wireless charging of industrial environment monitoring equipment: some industrial environment monitoring equipment such as temperature sensors. These devices are usually deployed in inaccessible or hazardous environments, and wireless charging technology eliminates the need for maintenance personnel to frequently enter these environments for charging operations.

With its unique charging method and wide range of applications, wireless charger pcb is gradually becoming an indispensable part of modern life. It provides great convenience for people with its convenient, efficient and safe features. With the continuous progress and innovation of technology, the application prospect of wireless charger circuit board will be broader, bringing more possibilities for our life and work.