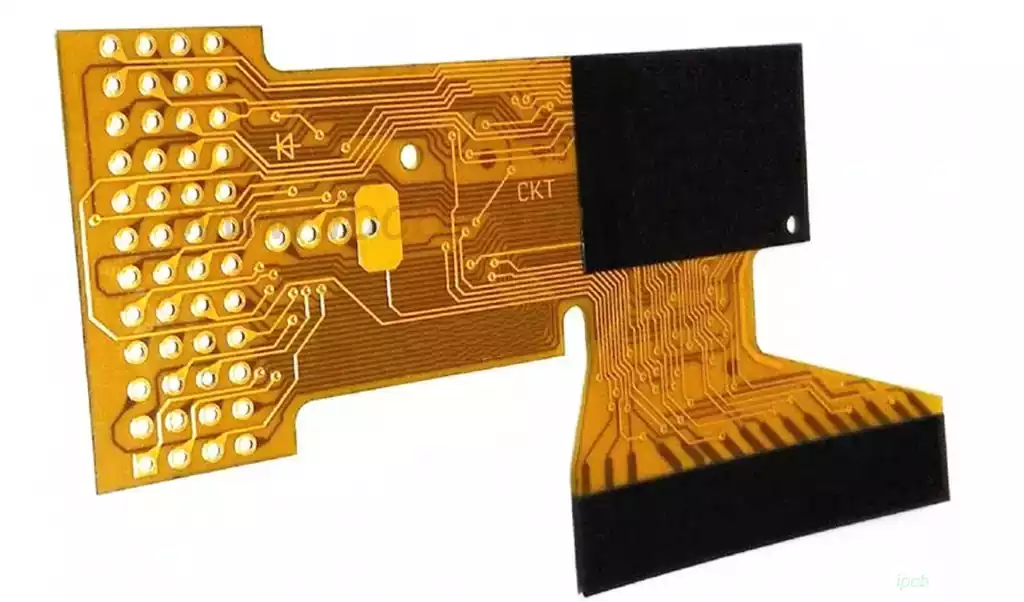

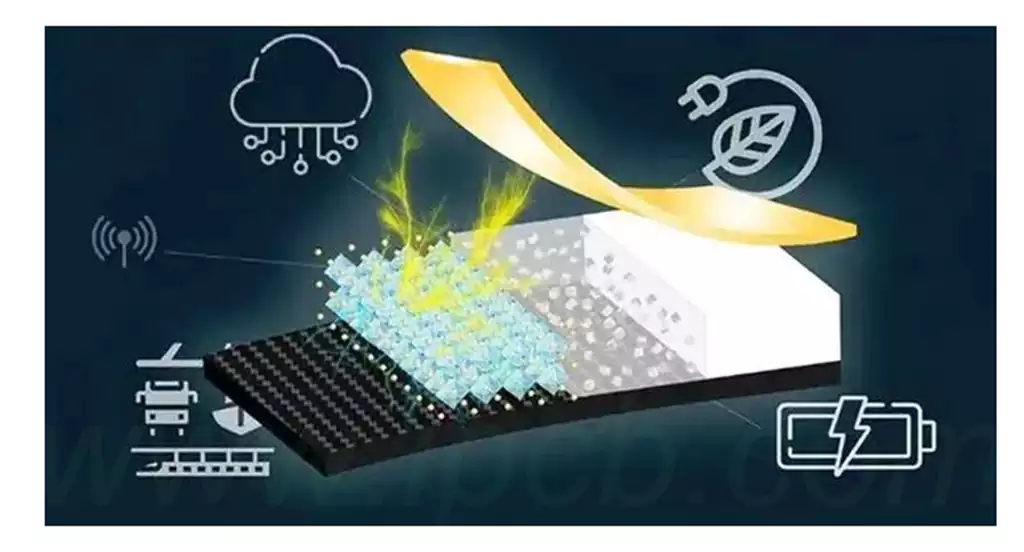

An energy harvesting PCB is a solution that integrates multiple energy harvesting technologies onto a circuit board to harvest and convert energy from the surrounding environment into electricity. It typically involves the use of technologies such as solar cells, thermoelectric generators, piezoelectric materials, or radio frequency (RF) collectors to self-power a device or improve battery life.

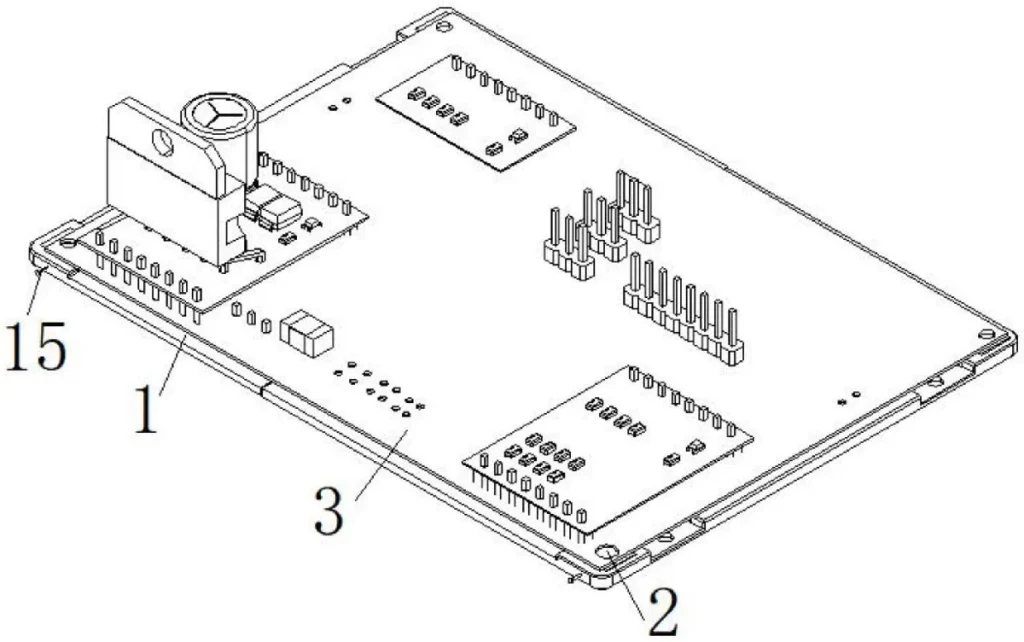

Energy harvesting PCB needs to be equipped with efficient power management circuits to manage the collected electrical energy. These power management systems typically include DC/DC converters, energy storage components such as capacitors or batteries, and voltage regulators to ensure that the output voltage is smooth and meets the power consumption requirements of the device. Effective power management can significantly extend the uptime of a device.

Energy harvesting PCBs typically contain the following key components:

Energy Harvester: responsible for capturing and converting energy from the environment, such as a photovoltaic module or thermoelectric generator.

Power Management Integrated Circuit (PMIC): manages and controls the harvested power, ensures a stable output voltage and effectively manages the charging process.

Energy Storage Module: Usually a capacitor or battery that stores the collected energy to ensure power is available when needed.

Output Interface: Connects to a load or other power supply device to ensure the efficient transmission and use of power.

Energy harvesting technologies mainly include the following:

Solar energy collection: utilizes photovoltaic cells to convert light energy into electricity. It is suitable for environments with sufficient light to provide long-lasting power for equipment.

Thermoelectric generator:Converts thermal energy into electrical energy through temperature differences, suitable for applications such as waste heat recovery.

Piezoelectric Power Generation System:Utilizes mechanical vibration or pressure to meet the power demand of the device,suitable for embedded and mobile devices.

RF energy harvesting:extracting energy from radio waves in the surrounding environment,suitable for low-power IoT devices

Application Scenarios for Energy harvesting PCB

- Internet of Things (IoT) devices

Energy harvesting PCB is increasingly used in Internet of Things (IoT) devices.Devices are often designed to require a long-term stable power supply, and energy harvesting technology can extend the battery life of devices or replace batteries by capturing ambient energy,providing a reliable power solution for sensors, actuators,and other devices. - Wearable Devices

In the design of wearable devices, it can significantly improve the functionality and convenience of the device.This technology can reduce the need for traditional batteries and extend the life of a device by harvesting environmental energy such as motion, temperature, and even solar energy. - Military Equipment

Power management for military equipment is also an important application area. Many military equipment requires long hours of operation and it is difficult to replace batteries, energy harvesting technology can help these devices to obtain continuous power, thereby enhancing operational efficiency. - Self-driving cars

In a self-driving car environment, it is possible to utilize the ambient energy around the vehicle to increase the power supply to internal devices, thus reducing the reliance on external charging facilities. This technology could turn the potential of driving intelligent transportation systems into reality. - Environmental Monitoring

Energy harvesting PCBs are also suitable for a variety of environmental monitoring devices.These devices can be deployed in remote areas and powered by ambient energy (e.g., solar or wind) without the need for frequent battery replacements, thereby reducing maintenance costs and increasing efficiency.

6.Smart City

In the construction of smart cities, it is possible to provide sustainable power for massively deployed sensor networks. These sensors can collect and transmit data that can enhance the intelligence of city management and services.

Difficulties and challenges in energy pcb design

- Selection of energy harvesting technology

Choosing the right energy harvesting technology is an important challenge when designing an energy harvesting PCB. Common energy harvesting methods include solar, mechanical vibration,thermal gradient and radio frequency.Each of these technologies has different power generation capabilities and applicable environments,and the designer needs to carefully evaluate the target application to select the most efficient harvesting method. - Power Management and Energy Storage

Energy harvesting systems typically only generate power at the microwatt level,so effective power management strategies are needed to optimize the energy supply.This includes the use of efficient DC/DC converters and intelligent power management circuits to ensure that energy storage components are efficient and reliable when charging.In addition,the choice of energy storage method is a major challenge,such as capacitors, chemical batteries or ultracapacitors, each of which has its own advantages and disadvantages and needs to be selected according to specific needs. - Overall efficiency of system design

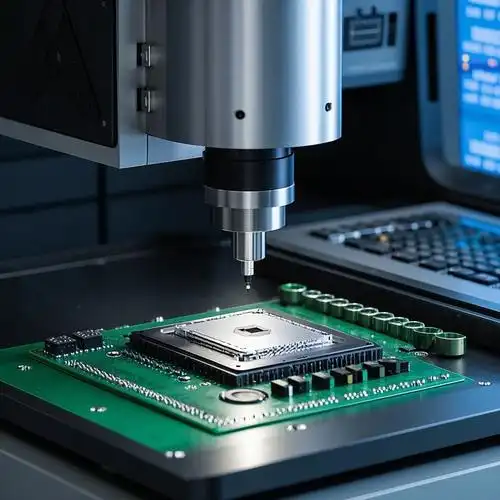

Since the ambient energy for energy harvesting is usually small, the overall energy efficiency of the system is particularly important. Designers need to make efforts to avoid wasting energy in all aspects, including hardware design and software optimization. Using low-power components and ensuring that circuit designs are optimized are key to achieving high energy efficiency. In addition, the design of intelligent power management will also have a direct impact on the power utilization of the system. - Electronic Components Selection and Compatibility

When selecting electronic components, designers need to consider the compatibility and integration of the components to avoid efficiency degradation due to component mismatch.Particularly in the case of customized designs,it may be necessary to work with manufacturers of Application Specific Integrated Circuits (ASICs), which can lead to high upfront investment and increased design complexity, thus affecting the feasibility of the project. - Environmental Adaptability and Sustainability

Energy harvesting systems are often deployed in harsh environments,so their design needs to be environmentally resilient.Designers need to consider temperature,humidity,vibration,and other external factors that can affect the efficiency and longevity of energy harvesting equipment. Therefore, choosing durable and reliable materials and designs is the key to meeting the challenge.

In the future, the design of energy harvesting PCB will focus on improving energy conversion efficiency and the application of multi-source energy integration technologies to accommodate the growing demand for smart devices. In addition, the exploration of new materials and the development of adaptive power management solutions will drive innovation and growth in this area.